Dry Type Transformer is an indispensable key device in our daily power system. Although it is not conspicuous, it ensures the safety and stability of electricity use. Let us understand its unique advantages and why it is so important in modern power applications.

What is The Dry-type Transformer?

Figure 1 Dry-type transformer diagram

A dry-type transformer is an electrical device that is cooled by air, rather than relying on oil to dissipate heat. Its design makes it particularly suitable for use in places where high safety and environmental protection requirements are required, such as shopping malls, hospitals, and schools. Because it does not use oil, it not only reduces the risk of fire but is also more environmentally friendly. Overall, dry-type transformers are a safe and reliable electrical device that plays an important role in many modern power systems.

Working Principle of Dry-type Transformer

Figure 2 What is a dry-type transformer

The working method of dry-type transformers is actually very intuitive. The current inside it generates heat when it passes through the coil. This heat is naturally dissipated through the air to keep the temperature of the equipment stable. Because it does not use oil cooling, its heat dissipation process is simpler, and there is no need to worry about oil leakage or other safety issues. It is this simple heat dissipation method that makes dry-type transformers more reliable and environmentally friendly.

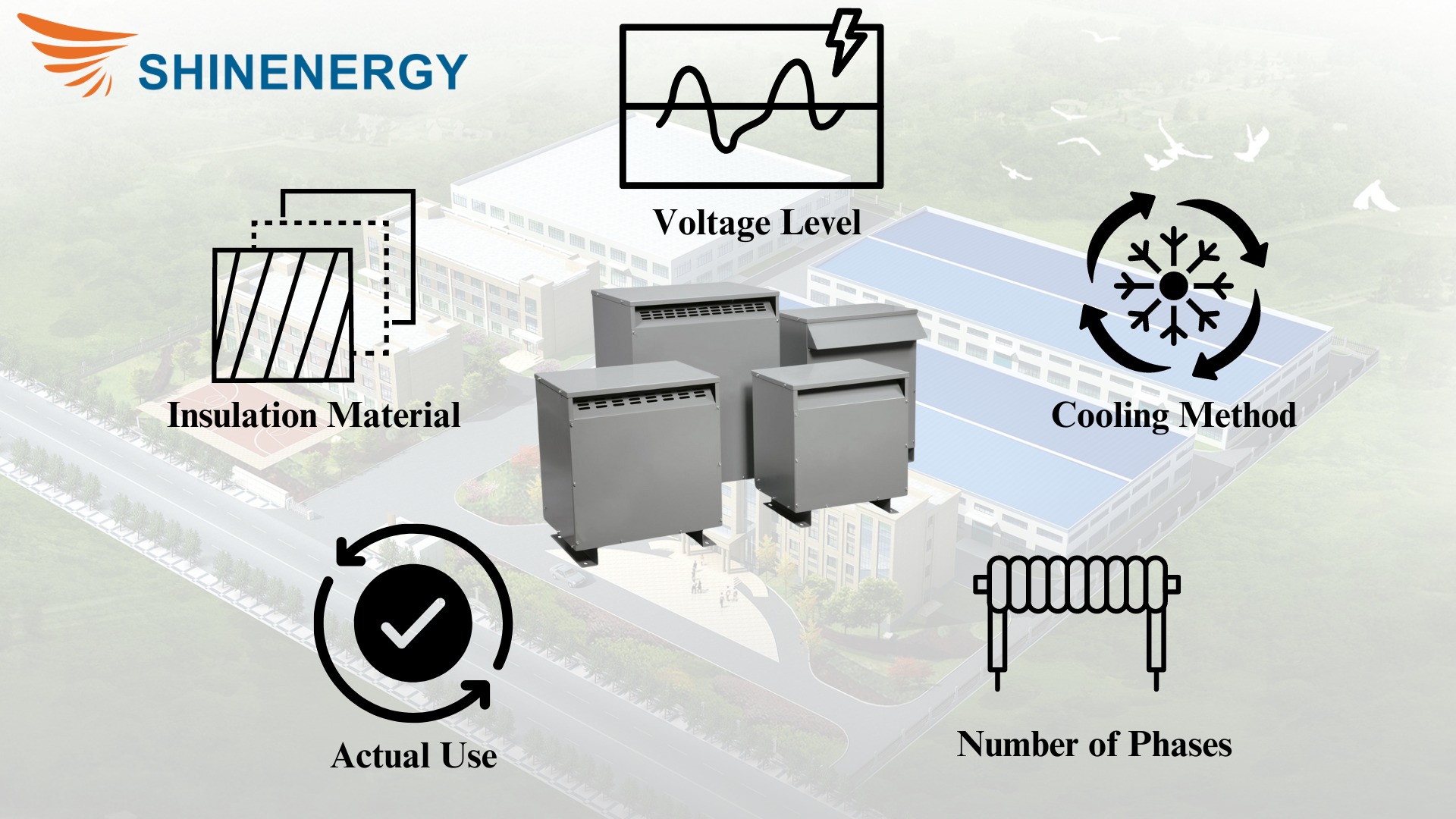

What Are The Dry Type Transformer Types?

Figure 3 Types of dry type transformer

Classified By Cooling Method

Uses natural air circulation for heat dissipation, suitable for environments with lower loads or stable temperatures.

Forced Air Cooling (AF)

Utilizes fans or other cooling devices to assist in heat dissipation, suitable for environments with higher loads or elevated temperatures.

Classified By Insulation Material

Epoxy Resin Cast Dry-Type Transformer

The coils are encapsulated in epoxy resin, providing moisture and dust resistance, making it suitable for humid or dusty environments.

NOMEX Paper Insulated Dry-Type Transformer

Uses high-temperature resistant NOMEX paper as the insulation material, ideal for high-temperature or harsh environments. The cast coil dry-type transformer is ideal for applications requiring robust mechanical strength and resistance to moisture, making it a reliable choice for challenging environments. On the other hand, the cast resin dry-type transformer is favored in commercial and residential buildings due to its durability, safety features, and minimal maintenance needs, ensuring consistent performance over time.

Classified By Voltage Level

Low Voltage Dry-Type Transformers

Suitable for voltages below 1000 volts, commonly used in residential areas, offices, and other low-voltage power distribution applications.

| 15 kva dry type transformer | 25 kva dry type transformer |

| 30 kva dry type transformer | 1000 kva dry type transformer |

Medium Voltage Dry-Type Transformers

Suitable for voltages between 1000 volts and 35 kilovolts, typically used in industrial parks, data centers, and similar settings.

High Voltage Dry-Type Transformers

Suitable for voltages above 35 kilovolts, commonly used in power plants, substations, and other large-scale infrastructure.

Ultra High Voltage Dry-Type Transformers

Suitable for voltages above 110 kilovolts, used in ultra-high voltage transmission systems, ideal for long-distance power transmission.

| 500 kva dry-type transformers | 750 kva dry-type transformers | 112.5 kva dry-type transformers | 150 kva dry-type transformers |

| 225 kva dry-type transformers | 1500 kva dry-type transformers | 1500 kva dry type transformer price | 2000 kva dry-type transformers |

| 2000 kva dry-type transformer dimensions | 2500 kva dry-type transformers |

Classified by Actual Use

Dry Type Distribution Transformers/Dry Type Pad Mounted Transformers

These transformers are used to step down high voltage from the power grid to a lower voltage suitable for everyday use in homes and businesses. The dry-type distribution transformer efficiently lowers the high voltage from the main grid, making it suitable for safe use in residential and commercial areas.

Dry-Type Power Transformer/Dry-Type Electrical Transformers/ Dry-Type Substation Transformer

These transformers are used for voltage conversion between power plants and transmission networks, and a dry-type power transformer is crucial in transmitting electricity from power plants to substations, where it is further distributed to end-users.

Dry-Type Current Transformers

These transformers convert AC to DC, and the dry-type current transformers are essential in applications requiring this conversion, especially in electrochemical processes or direct current equipment used in industrial settings.

Dry-Type Isolation Transformers

These transformers are used to isolate different sections of a circuit and dry-type isolation transformers are often employed to separate sensitive equipment from the main power source, thereby enhancing safety and reducing electrical interference.

Classified by Number of Phases

Single-Phase Dry-Type Transformers

Suitable for voltage conversion in single-phase power supplies, commonly used in homes and small commercial settings.

Three-Phase Dry-Type Transformers

Suitable for voltage conversion in three-phase power supplies, and is the mainstream choice for industrial and commercial applications.

Two-Phase Dry-Type Transformers (Less Common)

Used for voltage conversion in special power requirements or in legacy systems.

Dry-type step-down transformers

Dry-type step-down transformers reduce high voltage to a safer, usable level for residential and commercial applications.

Dry-type step-up transformers

Dry-type step-up transformers increase the low voltage to a higher level for efficient transmission in power generation and renewable energy systems.

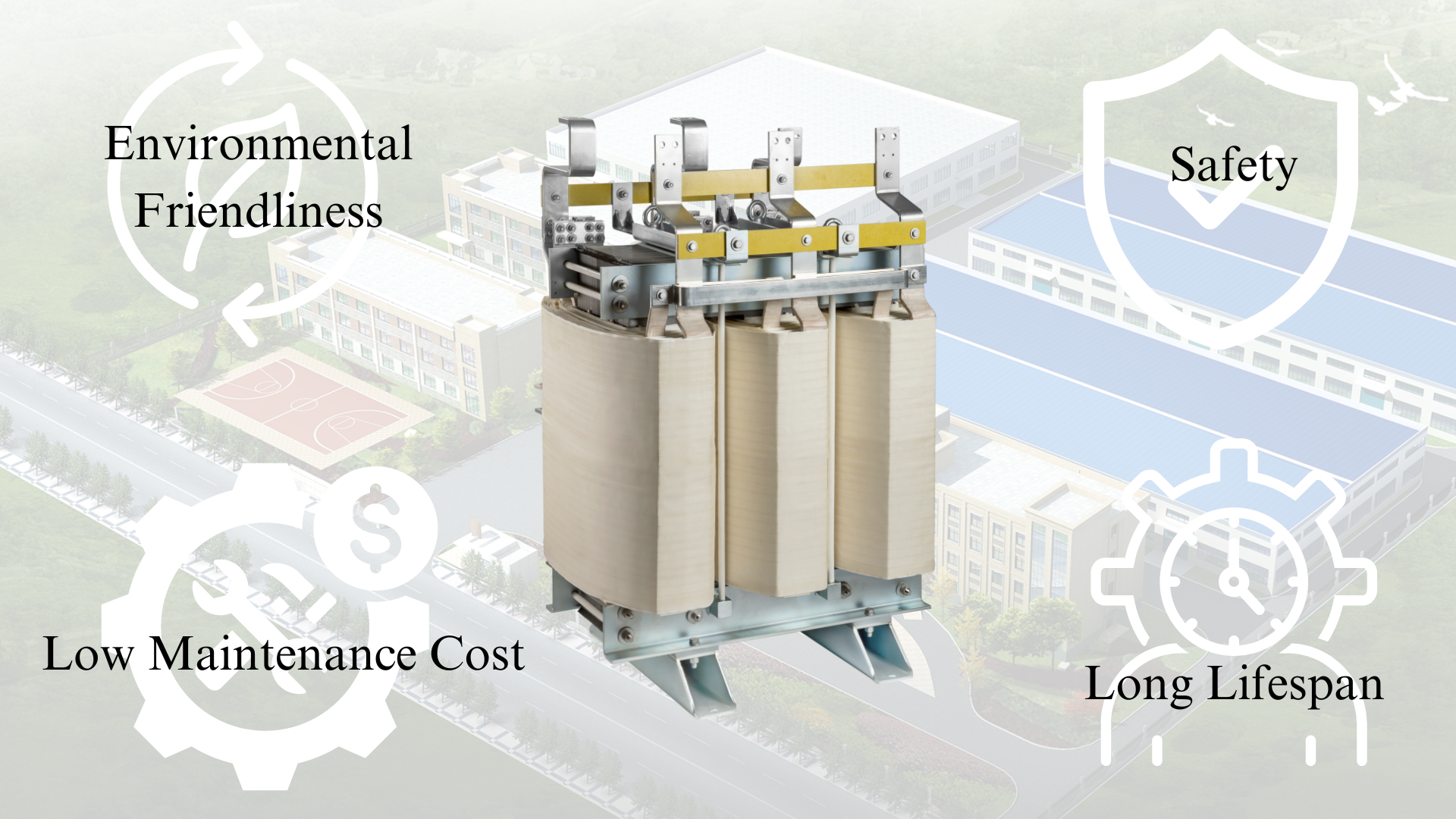

Advantages of Dry Type Transformer

Figure 4 Dry-type transformer advantages

- Environmental Friendliness: Oil-free design reduces the risk of pollution.

- Safety: No risk of fire or explosion.

- Low Maintenance Cost: Lower maintenance requirements compared to oil-immersed transformers.

- Long Lifespan: Durability and reliability ensure a long service life.

Dry Type Transformers Applications

Commercial and Residential Buildings

Figure 5-1 Commercial and Residential Buildings

Dry-type transformers are very common in places like shopping malls, office buildings, and residential areas. They are responsible for converting high-voltage electricity into a voltage suitable for daily use, ensuring that there will be no voltage problems when you use elevators, turn on lights, or use home appliances. Because dry-type transformers are safe and environmentally friendly, they are particularly suitable for use in places with a large number of people and high safety requirements.

Data Centers

Figure 5-2 Data Centers

Dry-type transformers are one of the core equipment in places like data centers that require uninterrupted power supply around the clock. They not only provide stable power but also prevent overheating or other power problems from affecting servers. Since data centers have very high requirements for safety and reliability, the oil-free design of dry-type transformers makes them more popular and reduces fire hazards.

Medical Facilities

Figure 5-3 Medical Facilities

Many equipment in hospitals have strict requirements for power supply, such as instruments in operating rooms, monitoring equipment, etc. Dry-type transformers can ensure a stable and reliable power supply for these key equipment, and their environmental protection and safety characteristics also reduce the risk of fire, which is especially important for places like hospitals.

Industry and Manufacturing

Figure 5-4 Industry and Manufacturing

In factories and manufacturing industries, dry-type transformers are responsible for powering various large machinery and production lines. They can handle high power demands and remain stable in high-temperature and high-load environments. Since these places usually have many devices and complex environments, the efficient heat dissipation and safety performance of dry-type transformers ensure continuous and smooth production.

6. Conclusion

Summary of the advantages and applications of dry-type transformers

Figure 6-1

Although dry-type transformers are usually not very noticeable, they play a vital role in our lives and work. They are highly safe, environmentally friendly and pollution-free, and relatively simple to maintain. This makes them an ideal choice for various places such as shopping malls, residential areas, factories, and hospitals. Dry-type transformers perform very well in both protecting personal safety and ensuring power stability.

Outlook for Future Development

Figure 6-2

Looking to the future, dry-type transformers will continue to play a greater role in various fields. With the development of technology, transformers will become more intelligent and may incorporate more monitoring and automation functions to further improve their efficiency and reliability. At the same time, as people pay more attention to environmental protection, the environmental advantages of dry-type transformers will also allow them to play a more important role in green energy and sustainable development. In general, dry-type transformers have broad prospects for future development and will continue to play an important role in meeting the growing demand for electricity.

FAQ

Are dry-type transformers filled with oil to reduce overheating?

What is the difference between an oil-type and a dry-type transformer?

What are the special structures of dry-type transformers?

Pingback: หา Influencer