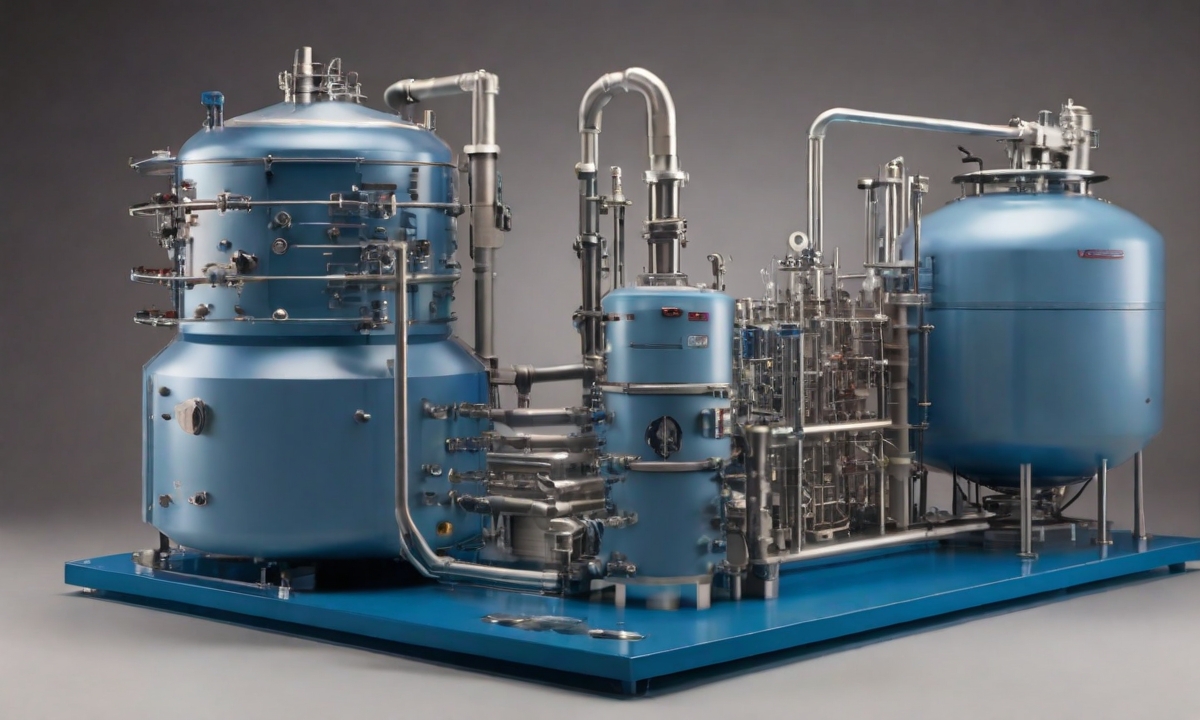

Custom designed reactors are essential for advanced industrial applications that require tailored solutions to meet unique performance demands. Reactor engineering plays a critical role in designing and developing reactors that can function effectively in challenging environments and variable conditions.

Understanding Custom Reactor Design

Custom reactor design is a fundamental aspect in the development of highly efficient industrial applications. Through tailored solutions and bespoke reactor design, manufacturers can optimize performance and reduce operational costs.

A key component of custom reactor design is reactor fabrication. Fabrication techniques are vital in ensuring that the reactor meets industry-specific demands while maintaining optimal functionality.

The design of custom reactors is unique to each industrial application. Industrial reactor design involves the integration of various components such as pumps, heat exchangers, and pressure vessels. Each component must be calculated carefully to ensure optimal performance.

The benefits of bespoke reactor design cannot be overstated. By utilizing specialized reactor design services, manufacturers can achieve unique solutions that address specific challenges in their processes. Custom reactor fabrication ensures that the reactor is tailored to the required specifications and has the desired functionality.

In conclusion, understanding the fundamental aspects of custom reactor design is crucial in achieving optimal performance in industrial applications. Effective reactor fabrication techniques, tailored solutions, and bespoke reactor design are essential in delivering operational efficiency and cost-effectiveness in manufacturing processes.

The Role of Reactor Engineering

Reactor engineering plays a crucial role in providing custom designed reactors for advanced industrial applications. With specialized reactor design, tailored solutions can be developed to meet specific industry requirements and optimize performance. The expertise of reactor engineering ensures that the reactor is designed precisely, meeting safety standards and regulatory requirements, resulting in a dependable product.

Specialized reactor design can help improve efficiency and reduce costs while providing the best solution for the given application. Selecting a reputable company that provides tailored reactor solutions ensures that the customized design is of the highest quality. Utilizing specialized reactor design allows industries to create the perfect reactor to meet their specific needs, improving production and efficiency overall.

In summary, reactor engineering plays a pivotal role in creating reactor designs that satisfy the unique demands of the industrial world. The tailored solutions offered by specialized reactor design provide businesses with the means for optimal performance in their industrial processes.

Factors Influencing Reactor Design

Custom designed reactors play a crucial role in industrial processes. However, designing a custom reactor is a complex process that requires taking into account various factors that influence the final design. Choosing the right reactor design service provider is crucial to ensure that the design meets the safety standards, regulatory requirements, and industry-specific demands.

Reactor design services offered by a reputable reactor design company can help to mitigate potential issues and ensure that the reactor design is optimal for the intended process. Some of the factors that influence custom reactor design include the type of reaction, reactants used, temperature, pressure, kinetics, and the desired product. Other factors that need to be considered before designing a custom reactor include the expected residence time, mixing requirements, and scalability.

Partnering with a reactor design company that has a proven track record of delivering tailored reactor solutions can help in developing a custom reactor that is suitable for the process at hand. The right reactor engineering expertise and specialized reactor design can ensure that the reactor meets complex and unique challenges required for advanced applications.

Key Considerations in Tailored Reactor Solutions

Developing tailored reactor solutions involves careful consideration of various factors to ensure optimal performance and efficiency. Custom designed reactors offer numerous benefits over standard solutions, including increased safety, improved productivity, and reduced costs. Partnering with specialized reactor manufacturing services can provide added value by leveraging their expertise in bespoke reactor design and fabrication.

Factors to Consider

- Specific industry requirements

- Budget and resources

- Regulatory compliance

- Safety considerations

- Operating conditions

Each of these factors provides critical insights into the design and manufacturing of custom reactors that meet unique requirements. By thoroughly evaluating them, tailored reactor solutions can be optimized for maximum effectiveness.

Benefits of Custom Designed Reactors

Custom designed reactors offer several advantages over off-the-shelf solutions:

- Increased safety

- Improved efficiency

- Bespoke solutions for specific requirements

- Reduced costs in the long run

Customized reactors tailor to specific applications, allowing for more precise control and optimal performance.

Value of Specialized Reactor Manufacturing Services

Partnering with specialized reactor manufacturing services offers the following benefits:

- Expertise in bespoke reactor design and engineering

- State-of-the-art facilities and technology

- Compliance with regulations and safety standards

- Customized solutions for specific applications

- Cost-effective services and reduced turnaround time

By working closely with experienced reactor manufacturing services, industries can benefit from their extensive knowledge and produce custom reactors tailored to their unique needs.

Achieving Precision in Reactor Design

Achieving precision in reactor design is critical in ensuring optimal performance of custom reactors for complex industrial applications. The importance of expert reactor engineering and design services cannot be overstated in achieving this precision. Reputable reactor design companies that specialize in tailored reactor solutions offer the expertise needed to optimize design and performance.

Through specialized reactor design, these experts can produce reactors that meet specific requirements unique to each industry or application. The use of computer modeling and simulation techniques can effectively analyze, optimize, and validate reactor designs, ensuring that they perform precisely as intended under various conditions.

Furthermore, reactor design services that specialize in tailored solutions are dedicated to continuous improvement, monitoring feedback from clients to make incremental changes over time that lead to further refinements and advancement in reactor design.

Industrial actors who seek to achieve optimal performance and precision in reactor design must partner with experienced and reputable reactor design services well-versed in reactor engineering to achieve the desired result. This includes utilizing specialized reactor design services that offer tailored solutions to meet specific client requirements while improving overall reactor performance, efficiency, reliability, and safety.

Advanced Technologies and Innovations in Reactor Design

As the demand for custom designed reactors continues to increase, there has been significant innovation in industrial reactor design and custom reactor fabrication. Experienced reactor design companies are utilizing advanced technologies and techniques to deliver optimized solutions that meet specific industry requirements and enhance performance.

The advancements in reactor design technology have revolutionized the way custom reactors are developed, manufactured, and deployed. With computer-aided modeling and simulation techniques, reactor engineering teams can test and optimize designs, leading to improved performance.

Other innovations in industrial reactor design include the use of new materials and coatings, instrumentation and control systems, and enhanced safety features. These advancements have allowed reactor design companies to deliver high-quality custom reactor fabrication and tailored solutions, resulting in enhanced process control and cost-effectiveness.

Partnering with a reputable reactor design company specializing in custom reactor fabrication can provide industries with access to the latest technologies and techniques in reactor design, ensuring tailor-made solutions that meet specific needs.

The Role of Computer Modeling in Reactor Design

In the field of custom reactor fabrication and design services, computer modeling is becoming an increasingly important tool for achieving optimal performance and cost-effectiveness. Through simulation and modeling techniques, reactor engineering experts can efficiently analyze and optimize designs, reducing development time and ensuring accuracy.

Computer modeling allows for rapid testing of different designs, materials, and operational scenarios. This iterative process enables reactor design engineers to fine-tune designs until they meet or exceed industry-specific requirements, resulting in tailored reactor solutions that are optimized for their intended application.

In addition to streamlining the design process, computer modeling also supports improved safety and reliability. By simulating the behavior of a reactor under a range of conditions, experts can identify and mitigate potential issues before they arise. This helps to ensure the safe operation of the reactor and minimizes downtime related to maintenance or repairs.

Overall, the role of computer modeling in reactor design cannot be overstated. By leveraging the power of simulation and modeling techniques, custom reactor fabrication and design services can deliver cost-effective, high-performance solutions that meet the precise needs of industrial applications.

Quality Assurance in Reactor Design and Manufacturing

Ensuring quality in reactor design and manufacturing is crucial for the optimal performance of custom-designed reactors. Industries need to partner with reliable reactor manufacturing services and reputable reactor design companies to achieve high-quality tailored reactor solutions.

Quality assurance in reactor design and manufacturing involves a comprehensive approach that covers design, fabrication, testing, and documentation. It ensures that custom reactors meet or exceed safety standards, regulatory requirements, and industry-specific demands.

Partnering with expert reactor design and manufacturing services providers facilitates access to specialized reactor design expertise, state-of-the-art technologies, and advanced manufacturing processes. This enables the efficient production of high-quality custom reactors that meet the unique requirements of each industry.

With the continuous advancements in the field of reactor engineering, reliable quality assurance practices are crucial in achieving precision, efficiency, and optimal performance in industrial processes.

Case Studies: Successful Custom Designed Reactors

In this section, we will showcase real-world examples of successful implementations of custom designed reactors. These case studies serve as compelling evidence of how bespoke reactor design and reactor engineering expertise can solve specific challenges and deliver exceptional performance.

Case Study 1: Specialized Reactor Design for Pharmaceutical Production

Our client, a leading pharmaceutical company, approached us for a tailored Reactor solution that could handle the complex chemistry and rigorous demands of their API production process. Our team of expert reactor engineers developed a specialized design with superior agitation and temperature control mechanisms, leading to a significant increase in the overall yield and quality of their final product.

Case Study 2: Custom Designed Reactors for Petrochemical Refining

In the petrochemical refining industry, effective catalyst distribution is critical. Our team worked on a bespoke reactor design that included advanced catalyst coating and hollow fiber membranes, ensuring uniformity and maximized efficiency. This custom solution led to improved product quality, increased production and significant cost savings for our client.

Case Study 3: Tailored Reactor Solutions for Polymer Production

For our client in the polymer production sector, we developed a custom designed reactor that offered superior mixing, a homogenous temperature distribution, and an advanced automated control system. This bespoke solution led to a substantial increase in polymer yield, reduced waste, and enhanced product quality.

These case studies demonstrate the inherent value of specialized and bespoke reactor design in achieving optimal performance for specific industrial processes. By partnering with experienced reactor engineering companies and utilizing tailored reactor solutions, businesses can significantly enhance their operations and stay ahead of the competition.

Future Trends in Custom Reactor Design

As the demand for advanced industrial applications continues to grow, custom reactor design is evolving to meet new challenges and opportunities. One of the key emerging trends is the integration of cutting-edge technologies into reactor engineering.

Advancements in artificial intelligence, machine learning, and IoT are transforming the way we design and fabricate custom reactors. Custom reactor fabrication is becoming more automated, efficient, and precise, thanks to innovative software and hardware solutions.

Another significant trend is the increased focus on sustainability in industrial reactor design. Many industries are exploring ways to reduce energy consumption, minimize waste, and enhance environmental performance. Innovative reactor engineering strategies are being developed to support these goals, such as the use of renewable energy sources and the integration of waste-management systems.

Overall, the future of custom reactor design looks promising, with exciting advancements on the horizon. As reactor engineering continues to evolve, industries will be able to achieve even greater precision, efficiency, and performance in their processes, driving innovation and growth in the industrial sector.

Conclusion

Custom designed reactors are essential components in advanced industrial applications, and the importance of tailored solutions cannot be overstated. Reactor engineering plays a crucial role in achieving optimal performance, and specialized reactor design can address specific industry requirements.

It is imperative to consider various factors that influence reactor design, including safety standards, regulatory requirements, and industry-specific demands. Utilizing reliable reactor design services from reputable companies can ensure the production of high-quality, custom reactors.

Expert reactor engineering and design services contribute to the optimal performance of custom reactors in complex industrial applications. Advanced technologies such as computer modeling and simulation techniques allow for efficient analysis and optimization, leading to enhanced performance and cost-effective custom reactor fabrication.

Quality assurance is critical in reactor design and manufacturing, and partnering with reliable reactor manufacturing services and reputable reactor design companies can ensure the delivery of tailored reactor solutions of the highest quality.

Successful implementations of custom designed reactors have been demonstrated through various case studies, illustrating how bespoke design can address specific challenges and deliver exceptional results.

As advancements and innovations continue to emerge in reactor engineering, the future of custom reactor design looks promising. Industries can anticipate a continued focus on precision, efficiency, and optimal performance in their processes.

FAQ

What are custom designed reactors?

Custom designed reactors are reactors that are specifically designed and tailored to meet the unique requirements of a particular industrial application. These reactors are engineered to optimize performance and efficiency, ensuring the best possible results for the specific processes they are designed for.

Why are tailored reactor solutions important?

Tailored reactor solutions are important because they allow industries to address their specific needs and challenges effectively. By customizing the design of reactors, industrial processes can be optimized for maximum efficiency, reliability, and safety.

How does reactor engineering contribute to custom reactor design?

Reactor engineering plays a crucial role in custom reactor design as it involves the use of specialized knowledge and skills to develop reactors that meet specific industry requirements. This includes considering factors such as reaction kinetics, thermodynamics, and mass transfer to ensure optimal performance and safety.

What is involved in custom reactor fabrication?

Custom reactor fabrication involves the manufacturing of reactors according to custom-designed specifications. This includes selecting the appropriate materials, components, and manufacturing techniques to ensure the reactor meets the desired performance, safety, and durability standards.

How can reactor design services benefit industries?

Professional reactor design services provide industries with the expertise and experience needed to develop reliable and efficient reactor designs. These services ensure that the reactors are designed to meet safety standards, regulatory requirements, and industry-specific demands, minimizing risks and optimizing performance.

What is the role of a reactor design company?

A reactor design company specializes in providing custom-designed reactor solutions to industries. They have the expertise and knowledge to develop tailored reactor designs that meet specific requirements, ensuring optimal performance and efficiency in industrial applications.

What factors should be considered in reactor design?

There are several factors that influence reactor design, including the specific industrial application, safety considerations, regulatory requirements, reaction kinetics, heat transfer, and mass transfer. These factors need to be carefully analyzed and considered to ensure the design meets the desired performance and safety standards.

How can tailored reactor solutions benefit industries?

Tailored reactor solutions offer numerous benefits to industries. They allow for optimized performance, improved efficiency, and enhanced safety in industrial processes. Custom designed reactors can also lead to cost savings and increased productivity by specifically addressing the unique needs and challenges of a particular application.

What is the significance of computer modeling in reactor design?

Computer modeling plays a crucial role in reactor design as it allows for efficient analysis and optimization. Through simulation and modeling, engineers can analyze various design parameters, predict the reactor’s behavior, and optimize its performance, leading to cost-effective custom reactor fabrication.

How can industries ensure quality in reactor design and manufacturing?

Industries can ensure quality in reactor design and manufacturing by partnering with reputable reactor manufacturing services and reactor design companies. These companies have the knowledge, expertise, and quality assurance processes in place to ensure the production of high-quality custom reactors that meet industry standards and specifications.

Can you provide examples of successful custom designed reactors?

Yes, there have been numerous successful implementations of custom designed reactors. For example, in the pharmaceutical industry, reactors have been tailored to accommodate specific chemical reactions, allowing for efficient and precise drug synthesis. In the petrochemical industry, custom reactors have been designed to handle unique feedstocks or catalytic processes, maximizing production efficiency.

What are some future trends in custom reactor design?

The future of custom reactor design is likely to involve advancements in the use of renewable energy sources, integration of digital technologies for real-time monitoring and control, and further optimization of reactor designs for enhanced sustainability. Additionally, increased automation and artificial intelligence in reactor design and operation are expected to play a significant role in improving efficiency and productivity.