An autotransformer is one of the methods used to adjust voltage levels efficiently in various electrical systems. The autotransformer is an efficient and economical electrical device used in a wide range of industrial and commercial applications. From motor starting to voltage regulation, it stands out for its compact design and efficient performance. In this article, we will unveil the core principles, advantages, and practical applications of autotransformers to help you quickly understand the unique role of this device in power systems.

Figure 1 auto transformer diagram

What is an auto transformer ?

Figure 1-1 what is an autotransformer/autotransformer definition

An autotransformer is a unique type of transformer that has only one winding and achieves voltage regulation through different taps. Simply put, instead of requiring two separate windings, primary and secondary, as in a conventional transformer, it serves as both input and output through the same winding. This structure gives the autotransformer a significant advantage in size, cost and efficiency.

What are autotransformers used for?

Figure 2 the figure shows an autotransformer

In practice, autotransformers are mainly used where voltage changes are required without strict electrical isolation. Transformers automatic adjustment systems help regulate voltage levels without the need for manual intervention. For example, in photovoltaic power generation systems, autotransformers are used to regulate the output voltage to ensure voltage matching between the solar array and the grid. Between large-scale energy storage batteries and the grid, an autotransformer can balance the voltage to optimize the energy storage and release process. In data centers, autotransformers are often used as voltage regulators to ensure a stable power supply for server equipment.

What is the principle of autotransformers?

Figure 3 autotransformer construction

In an autotransformer, the input voltage is applied across the entire winding. By selecting a specific tap along the winding, a fraction of this input voltage can be output as a lower or higher voltage, depending on the tap position. Essentially, a part of the same winding acts as both the primary and secondary circuit, which reduces the amount of copper or aluminum required, making it more compact and cost-effective than conventional transformers.

Imagine a factory that needs to adjust the voltage to operate machinery at different power levels. A Victron autotransformer can step down voltage for lower power needs or step up for higher demands by selecting the right tap. This flexibility supports efficient energy management and minimizes losses, making autotransformers ideal for industrial machinery, HVAC systems, and renewable energy applications like solar inverters.

What is the difference between transformer and autotransformer?

Figure 4 transformer vs autotransformer

What are the advantages of an autotransformer?

1. Cost-Effectiveness

Figure 4-2 auto transform

Autotransformers use a single winding instead of separate primary and secondary windings, which reduces the amount of copper or aluminum required. This design makes them more economical to manufacture, making them a budget-friendly option for applications where electrical isolation isn’t a strict requirement.

Example: In commercial buildings, automatic transformer are used to adjust voltage levels for lighting systems or HVAC units. By using automatic transformer, building owners can achieve reliable voltage regulation without incurring the higher costs associated with traditional transformers.

2. High Efficiency

Figure 4-3 three phase auto transformer

Due to the shared winding, automatic transformer experience fewer energy losses, especially copper losses, compared to conventional transformers. This makes them highly efficient, particularly in applications with a small voltage difference between the input and output. List three other advantages of using reference points, such as improved accuracy, easier alignment, and enhanced consistency in measurements.

Example: In renewable energy systems, such as solar power plants, automatic transformer are used to regulate voltage levels with minimal energy loss. This efficiency is critical for maximizing energy output and ensuring that as much power as possible flows into the grid or battery storage system.

3. Compact Size and Lightweight

Figure 4-4 auto transformer diagram

The single-winding design means auto transformer are generally smaller and lighter than equivalent two-winding transformers. This compactness is beneficial in applications where space is limited or where equipment mobility is a priority.

Example: In data centers, where space is at a premium, auto transformer can be used to stabilize voltage for sensitive electronics without taking up too much rack or floor space. This makes them ideal for supporting high-density server setups.

4. Voltage Flexibility

Figure 4-5 auto transformer symbol

Autotransformers can easily adjust the output voltage by simply changing the tap on the winding. This flexibility allows for fine-tuning of voltage levels, which is useful in applications where variable voltage output is required.

Example: In industrial motor control, auto transformer allow for smooth voltage adjustments to manage motor speed and reduce startup current. This capability not only extends motor life but also improves overall operational efficiency.

5. Improved Regulation

Figure 4-6 autotransformer definition

Autotransformers generally provide better voltage regulation, meaning they maintain a stable output voltage even with varying load conditions. This stability is beneficial in scenarios where consistent power delivery is crucial.

Example: In electrical testing and calibration laboratories, auto transformer are often used to deliver precise, stable voltage outputs for equipment testing. Consistent voltage regulation ensures accurate test results and prevents equipment malfunction due to voltage fluctuations.

What is a disadvantage of an autotransformer?

Figure 4-7 disadvantageous meaning

1. No Electrical Isolation

Figure 4-8 auto transform

In a traditional transformer, the primary and secondary windings are separate, providing complete electrical isolation between the input and output. However, in an automotive transformer, both the input and output share a common winding, meaning there’s no isolation. This lack of isolation can be a safety risk in situations where protection from high voltage is needed. An isolation transformer has the same input and output voltages, providing electrical isolation without altering the voltage level. An isolation transformer has the same input and output voltages, which helps to provide safety by isolating different sections of a circuit.

Example: In high-voltage industrial settings, using a powerstat variable autotransformer can transfer faults or high-voltage spikes from the primary to the secondary side, risking connected devices and personnel. Therefore, variable transformers are generally avoided in applications requiring electrical isolation, like medical or sensitive instrumentation.

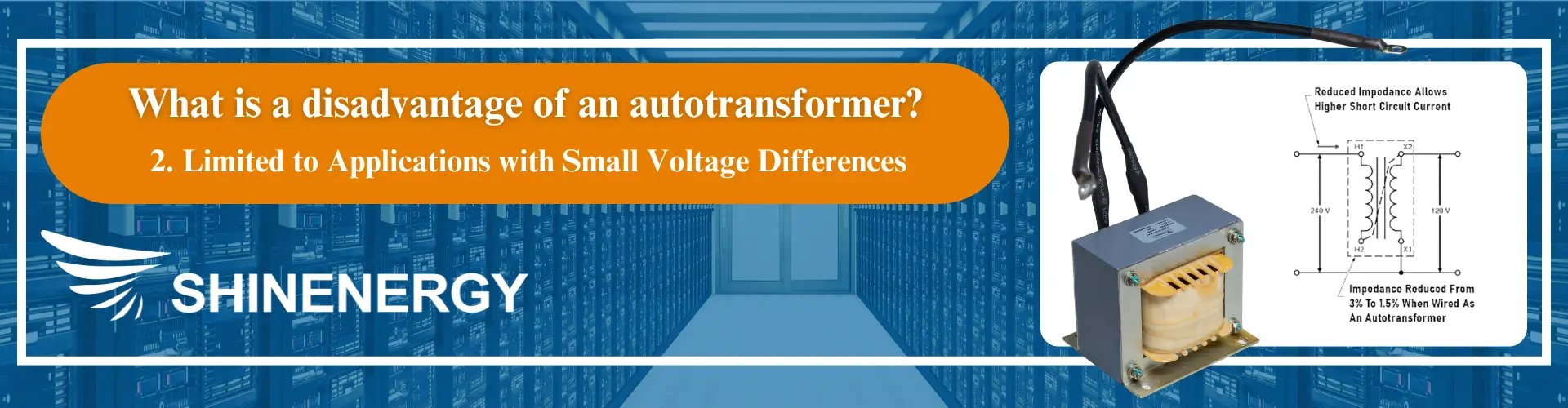

2. Limited to Applications with Small Voltage Differences

Figure 4-9 primary side of transformer

Autotransformers are most efficient and cost-effective when there is a relatively small difference between the input and output voltage. When a significant voltage change is needed, a conventional transformer with separate windings is often more practical and safer.Transformer auto converting enables seamless adjustment of voltage levels to match the requirements of different electrical systems.Example: To step down from a high voltage like 11kV to 400V, a traditional transformer is preferred. A variable voltage transformer would require a complex design and pose higher risks, offsetting its cost and efficiency benefits.

3. Higher Short-Circuit Current Risk

Figure 4-10 autoformer

The shared winding structure in autotransformers can lead to higher short-circuit currents, risking overheating or damage without proper protection, making them more vulnerable than traditional transformers. Three-phase autotransformers are widely used to adjust voltage in three-phase systems with high efficiency and lower material costs.

Example: In power distribution networks, a fault on the load side of an variable transformer can result in high fault currents that could damage the transformer if protection systems like circuit breakers or fuses fail to activate in time. This risk requires careful design and monitoring, which can add complexity and cost.

4. Increased Ground Fault Potential

Figure 4-11 autotransformer vs transformer

Since the winding is common to both primary and secondary circuits, any fault on the ground or neutral side can affect both sides of the circuit, increasing the risk of ground faults.An autotransformer is one of the methods used to efficiently change voltage levels in power distribution systems. Transformer bonding is essential for ensuring safety and preventing electrical faults by creating a secure ground connection.

Example: In settings like data centers, where power quality and fault tolerance are crucial, an auto transforming transformers could expose sensitive electronic systems to ground faults, potentially causing operational disruptions or equipment damage.

Is an autotransformer right for my application?

Figure 5 application of autotransformer

1. Voltage Regulation Needed

Figure 5-1 symbol of autotransformer

Autotransformers are best suited for situations where voltage differences are small. For example, if your application requires voltage regulation within a small range, or a voltage range such as 400V to 450V, then an variac transformer may be an ideal choice because it is efficient and inexpensive to regulate voltage within this small range. A transformer has a primary voltage of 115 V, allowing it to step up or step down the voltage as needed for various applications.

Example: In industrial motor control, variac transformer are used to reduce starting current, which can reduce the current surge when the motor starts. If your device has similar needs, an variac transformer may be a good fit.

2. Whether Electrical Isolation is Required

Figure 5-2 autotransformer advantages

If your application requires high electrical isolation (for example, high and low voltage circuits need to be isolated for safety reasons), an autotransformer may not be suitable. Because its structure does not provide electrical isolation, which means that the input and output are directly connected. In high-risk or isolation-required scenarios, such as medical equipment or precision instruments, a traditional two-winding transformer may be safer.

Example: If you are using a transformer in a photovoltaic system, and the system needs to isolate the AC grid and the DC side battery, a two-winding transformer is more suitable.

3. Size and Cost

Figure 5-3 autotransformer for sale

Autotransformers are generally more compact and less expensive than traditional transformers. If your application has limited space and a tight budget, an autotransformer is an ideal choice due to its simple structure and low cost. Auto transformation is a technique used to adjust voltage levels with a single winding, making it efficient for specific applications.

Example: In a data center, an 3 phase auto transformer can be used to adjust the supply voltage to ensure stable server operation while saving valuable space and cost.

4. Fault risk and protection measures

Figure 5-4 autotransformer grounding

Autotransformers have a higher risk of short circuits and ground faults, so if your application environment is prone to these, extra protection is necessary. Variac transformers also increase short circuit current risk; if your application cannot handle high short circuit currents, a conventional transformer may be a better choice.

Example: In power transmission systems, variable transformers are often equipped with additional protection devices (such as circuit breakers) to prevent short circuits when used for voltage regulation. If your system cannot afford this additional protection cost, it may be more practical to use a two-winding transformer.

Conclusion

Figure 6 three phase auto transformer

Shinenergy tailors unique 3 phase auto transformer for you. Our products meet the demands of power systems, industrial equipment, photovoltaic storage, and more, with designs optimized for your specific needs. From size and efficiency to protection, we offer precise customization to ensure stable operation and cost savings.

Choose Shinenergy, you will get an autotransformer that is not only highly adaptable but also durable. Let us help you easily meet power challenges and experience the perfect combination of technology and customized services.

FAQ

What are the advantages and disadvantages of automatic?

Automatic systems offer clear benefits, including increased efficiency, consistent quality, and cost savings over time by reducing manual labor. However, they come with some drawbacks, such as high setup costs, reliance on technology (making them vulnerable to malfunctions), and the potential for reducing job opportunities in certain roles.

Which winding of a transformer is connected to the load?

The secondary winding of a transformer is connected to the load. This winding receives the transformed voltage from the primary winding and delivers it to the load at the required level, whether stepped up or down. An isolation transformer has identical input and output voltages.

What is the voltage supplied to the autotransformer called?

The voltage supplied to the autotransformer is called the primary voltage or input voltage. This is the initial voltage applied to the autotransformer’s winding, which is then adjusted through taps along the winding to provide the desired output voltage level.

Pingback: jav

Pingback: feestopdemarkt

Pingback: ซื้อเหล้าออนไลน์

Pingback: endoliftX ที่ไหนดี

Pingback: alyosha video