How do common transformer sizes affect selection? From kVA ratings to physical dimensions, this guide walks you through different transformer specifications comparisons and application scenarios to help you make an informed choice.

P1- transformer dimensions chart

Understanding What “Transformer Size” Really Means

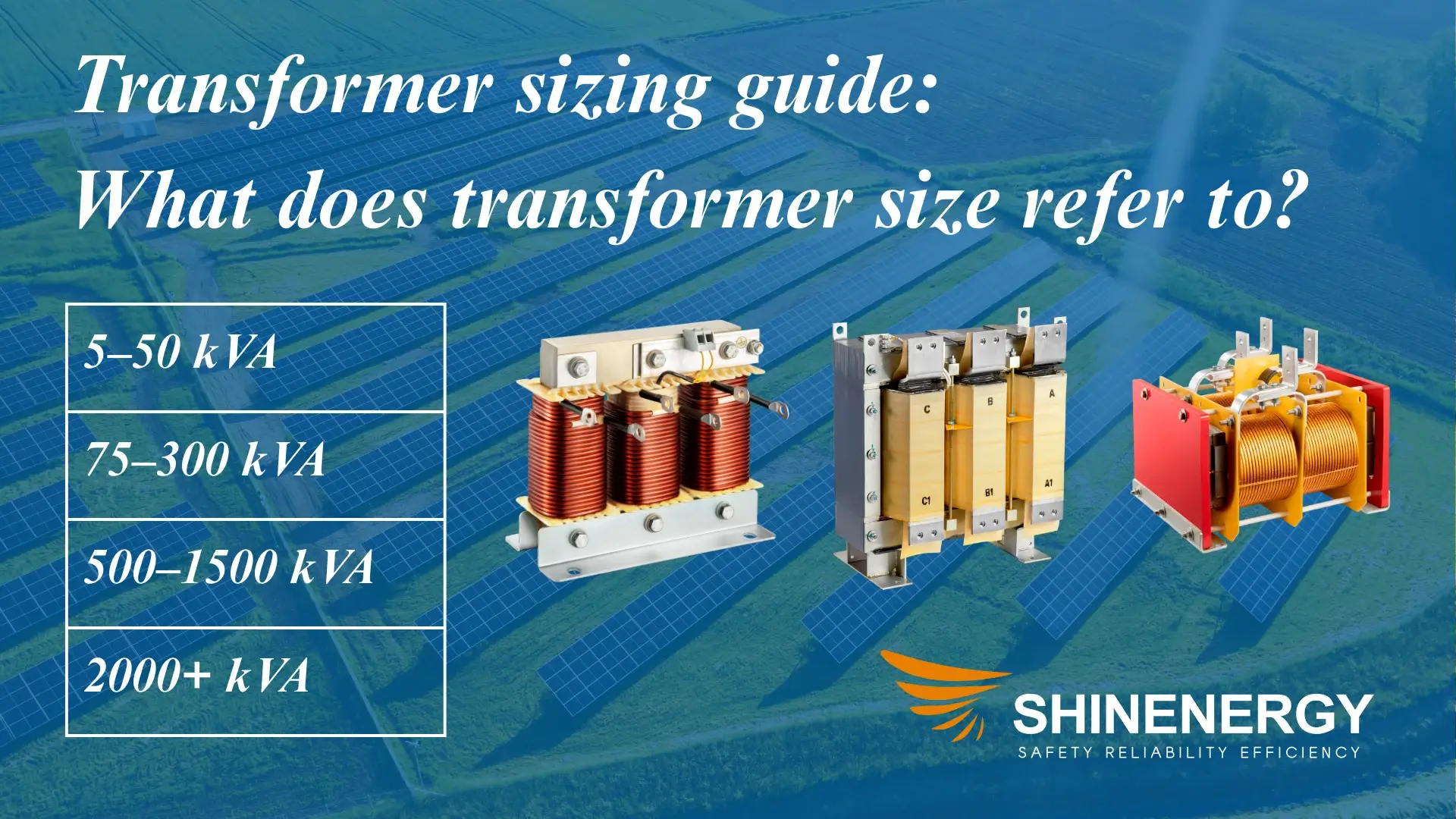

Transformer sizing guide: What does transformer size refer to?

P2- transformer size chart

The term “transformer size” generally includes both the rated power capacity and the physical dimensions of the equipment. It involves not only the external footprint but also key electrical performance indicators. During the selection process, transformer size determines the suitability for the operating environment, load capacity, and compatibility with the power distribution system.

In engineering design, procurement, and installation, transformer size is a critical parameter. Capacity rating, physical size, and voltage level together impact operational safety and overall system efficiency.

The Relationship Between Capacity, Physical Size, and Voltage Rating

P3- transformer kva ratings

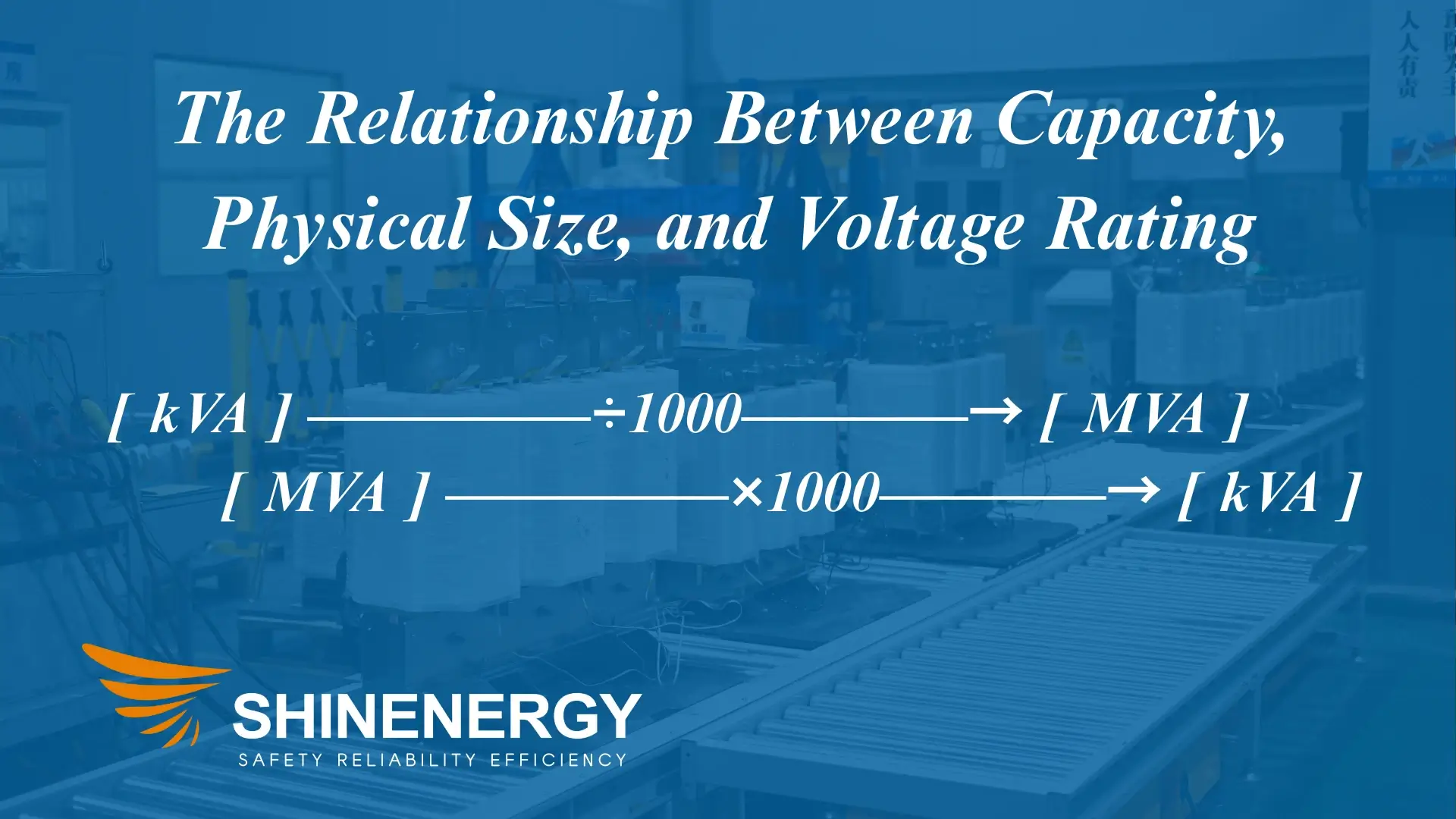

Transformer capacity is measured in kVA or MVA, indicating how much load the unit can handle. A higher capacity corresponds to higher current, which requires thicker conductors and more windings. As a result, the enclosure becomes larger and heavier.

However, physical size is not determined by capacity alone. Cooling method, voltage class, and insulation design also influence the overall volume. For example, a 1000 kVA dry-type transformer is often larger than an oil-immersed one due to the need for enhanced airflow and insulation clearance.

Higher voltage ratings require wider insulation distances. This affects the height, winding arrangement, and clearances within the unit. High-voltage transformer kva ratings typically feature larger housings and heavier support structures.

Why Transformer Size Matters in Real Applications

Size a transformer directly affects cable routing, installation layout, transport logistics, and ease of maintenance. In confined rooms, a compact transformer helps save space. In outdoor settings, a robust structure improves ingress protection and thermal performance.

Undersized capacity can cause overloading and shorten service life. Oversized specifications increase cost and reduce energy efficiency. Choosing the right transformer size ensures a balance between performance and cost, supporting long-term system reliability.

Breaking Down Transformer Ratings

P4- transformers size chart

What is kVA Capacity?

kVA (kilovolt-ampere) is the unit used to measure a transformer’s apparent power output. The larger the kVA rating, the greater the load the transformer can support. Higher capacities are suitable for more demanding electrical systems.

Different standard transformer sizes correspond to different kVA classes. Ranging from 5 kVA to several thousand kVA, each class is linked to specific application types. The selected capacity must exceed the maximum expected load current and include a safety margin to ensure long-term stable operation.

Basic Understanding of Input/Output Voltage, Frequency, and Impedance

Rated voltage refers to the designed operating voltage at both the primary and secondary terminals. The input voltage determines the primary winding configuration, while the output voltage must match the secondary load. Voltage class impacts internal clearances and coil layout, which ultimately influence transformer size.

Standard power frequencies are typically 50 Hz or 60 Hz. Frequency affects core design, material selection, and energy loss patterns. North America typically uses 60 Hz; Europe and Asia use 50 Hz. Transformers are frequency-specific and cannot be interchanged across systems.

Impedance is the combined value of a transformer’s internal resistance and reactance, expressed as a percentage. It affects short-circuit current and voltage stability. Higher impedance reduces fault current but may lower efficiency. Impedance selection must consider transformer capacity and system protection requirements.

Common Standards: ANSI, IEEE, and IEC

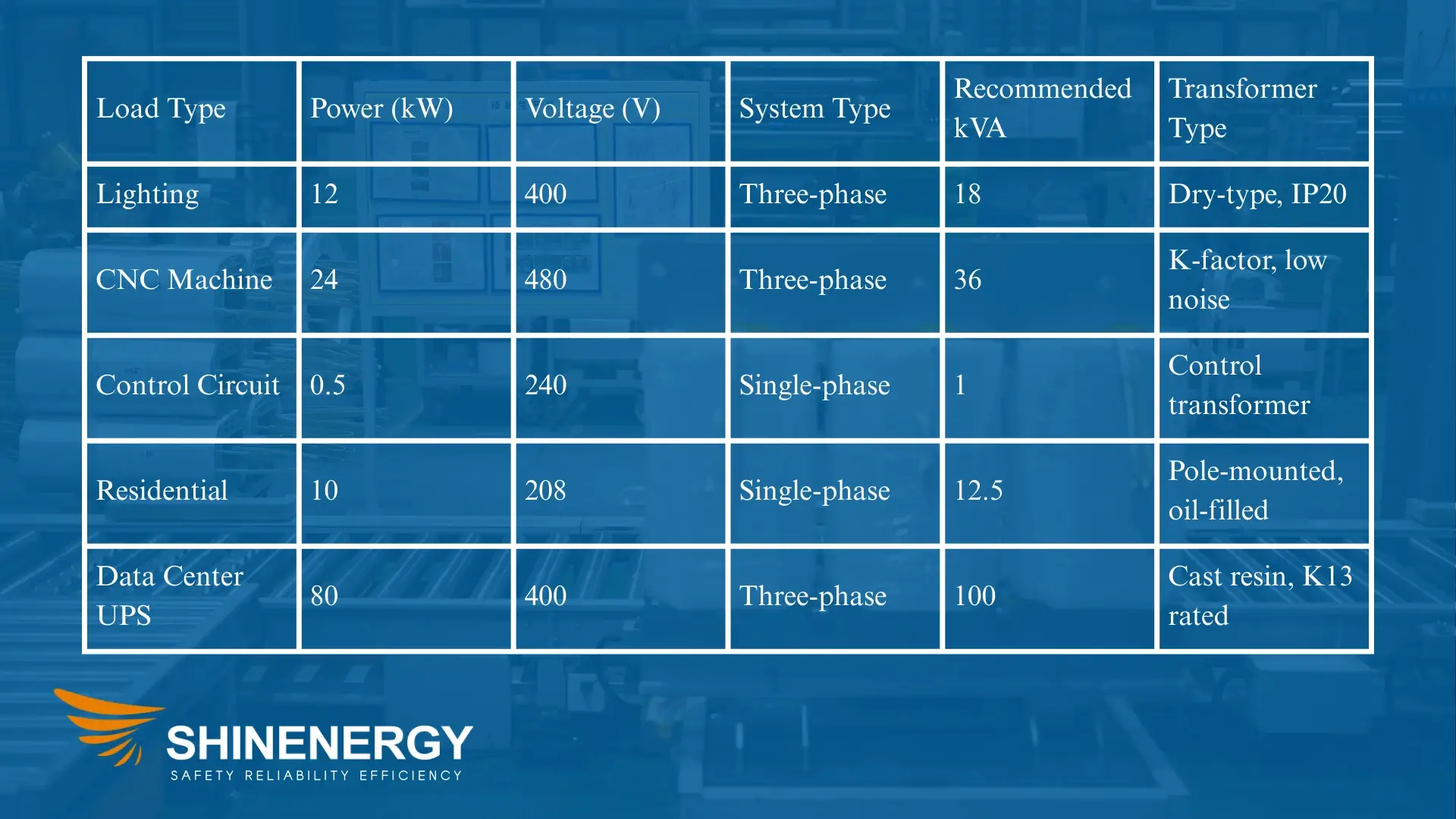

| Load Type | Power (kW) | Voltage (V) | System Type | Recommended kVA | Transformer Type |

| Lighting | 12 | 400 | Three-phase | 18 | Dry-type, IP20 |

| CNC Machine | 24 | 480 | Three-phase | 36 | K-factor, low noise |

| Control Circuit | 0.5 | 240 | Single-phase | 1 | Control transformer |

| Residential | 10 | 208 | Single-phase | 12.5 | Pole-mounted, oil-filled |

| Data Center UPS | 80 | 400 | Three-phase | 100 | Cast resin, K13 rated |

P5- transformer selection chart

ANSI and IEEE are widely used in North America and apply to industrial, commercial, and utility-grade transformers. These standards cover structural safety, electrical performance, and testing requirements.

IEC (International Electrotechnical Commission) standards are globally recognized and favored for international projects. IEC emphasizes energy efficiency and environmental compliance, while ANSI/IEEE prioritize dielectric strength and thermal stability.

Different standards may define typical transformer sizes and classifications slightly differently. Selecting the appropriate standard depends on the region and regulatory environment of the project.Transformers are rated according to their apparent power output, typically measured in kVA or MVA.

Common Transformer Sizes and Their Applications

Typical Capacity Ranges for Residential, Commercial, and Industrial Use

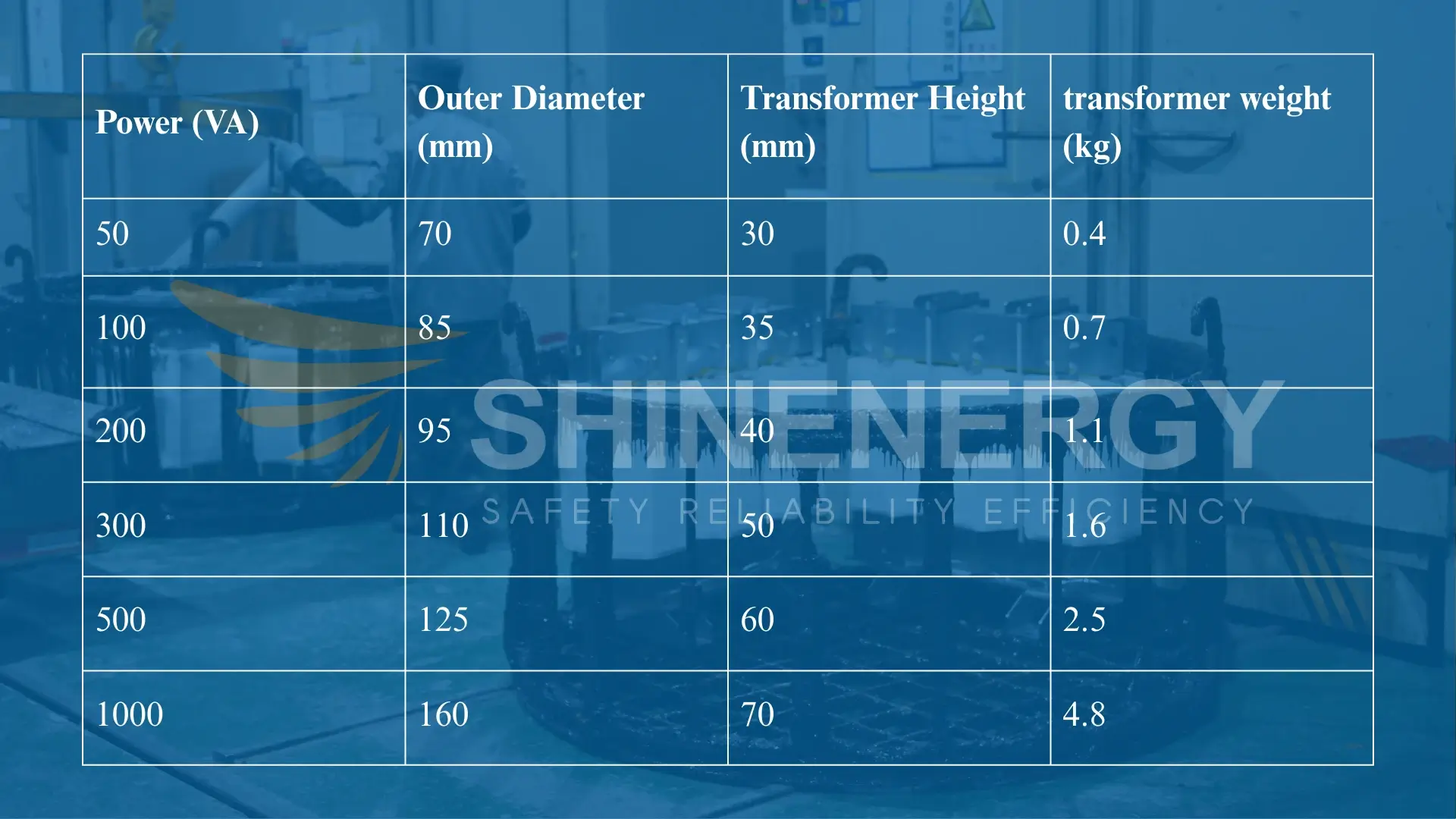

| Power (VA) | Outer Diameter (mm) | Transformer Height (mm) | transformer weight (kg) |

| 50 | 70 | 30 | 0.4 |

| 100 | 85 | 35 | 0.7 |

| 200 | 95 | 40 | 1.1 |

| 300 | 110 | 50 | 1.6 |

| 500 | 125 | 60 | 2.5 |

| 1000 | 160 | 70 | 4.8 |

P6- toroidal transformer dimensions chart

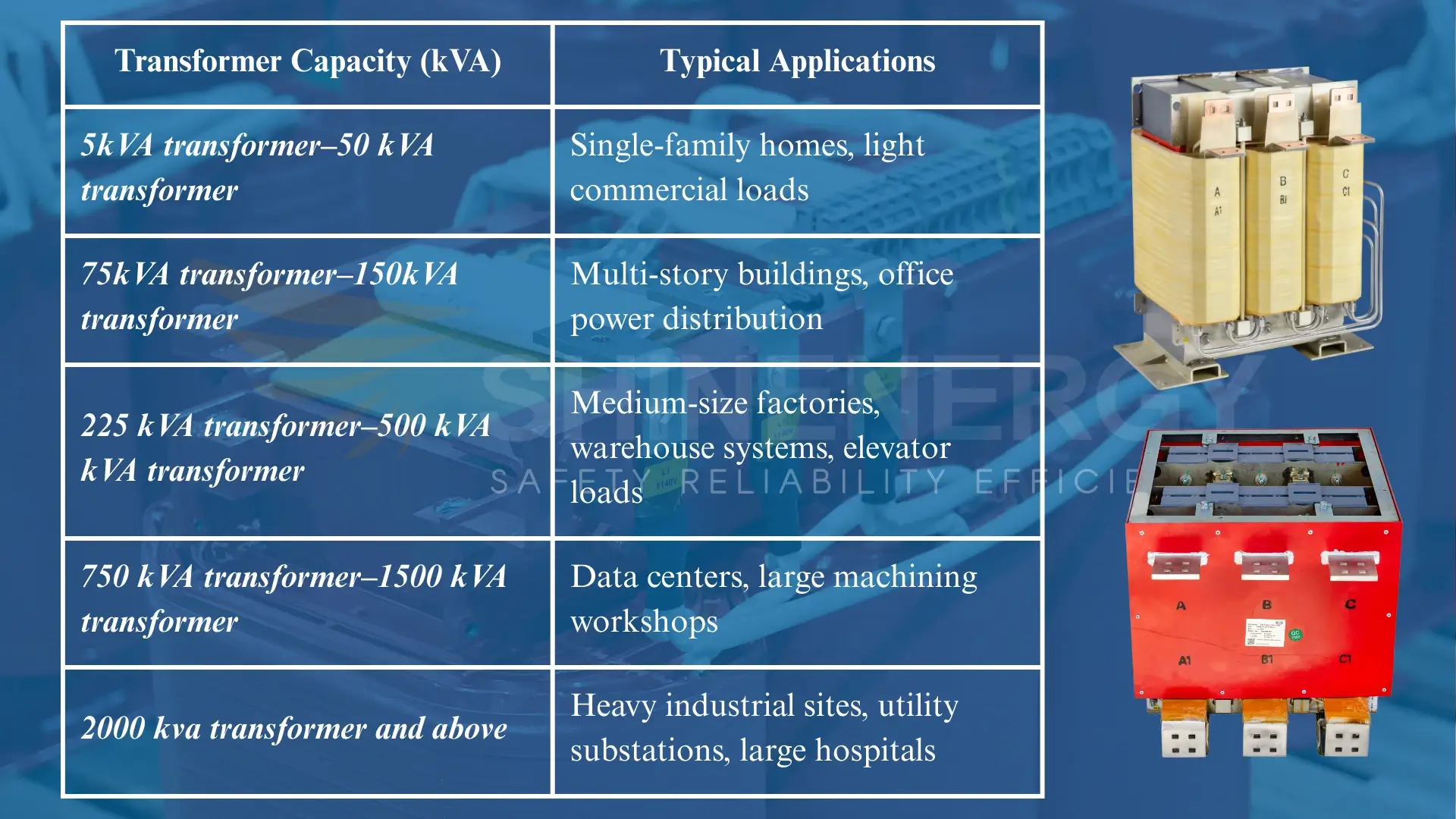

Different electrical environments require different transformer specifications. Residential systems typically use small transformer standard sizes ranging from 5 kVA to 50 kVA. These units are suitable for single-family homes, small apartment buildings, and low-power appliances.

Commercial applications—such as office buildings, elevator systems, and lighting networks—usually require transformer capacities between 75 kVA and 500 kVA. As capacity increases, changes occur in physical size, terminal configuration, and cooling method.

Industrial environments demand larger capacities. Facilities like manufacturing plants, heavy equipment operations, and data centers often use transformers rated at 750 kVA or higher. Heavy-duty applications may require transformer size of 2500 kVA or more. These high-capacity units provide greater load support and incorporate more advanced thermal management systems.

Common kVA Capacity and Usage Scenarios

| Transformer Capacity (kVA) | Typical Applications |

| 5kVA transformer–50 kVA transformer | Single-family homes, light commercial loads |

| 75kVA transformer–150kVA transformer | Multi-story buildings, office power distribution |

| 225 kVA transformer–500 kVA kVA transformer | Medium-size factories, warehouse systems, elevator loads |

| 750 kVA transformer–1500 kVA transformer | Data centers, large machining workshops |

| 2000 kva transformer and above | Heavy industrial sites, utility substations, large hospitals |

P7-transformer sizing table

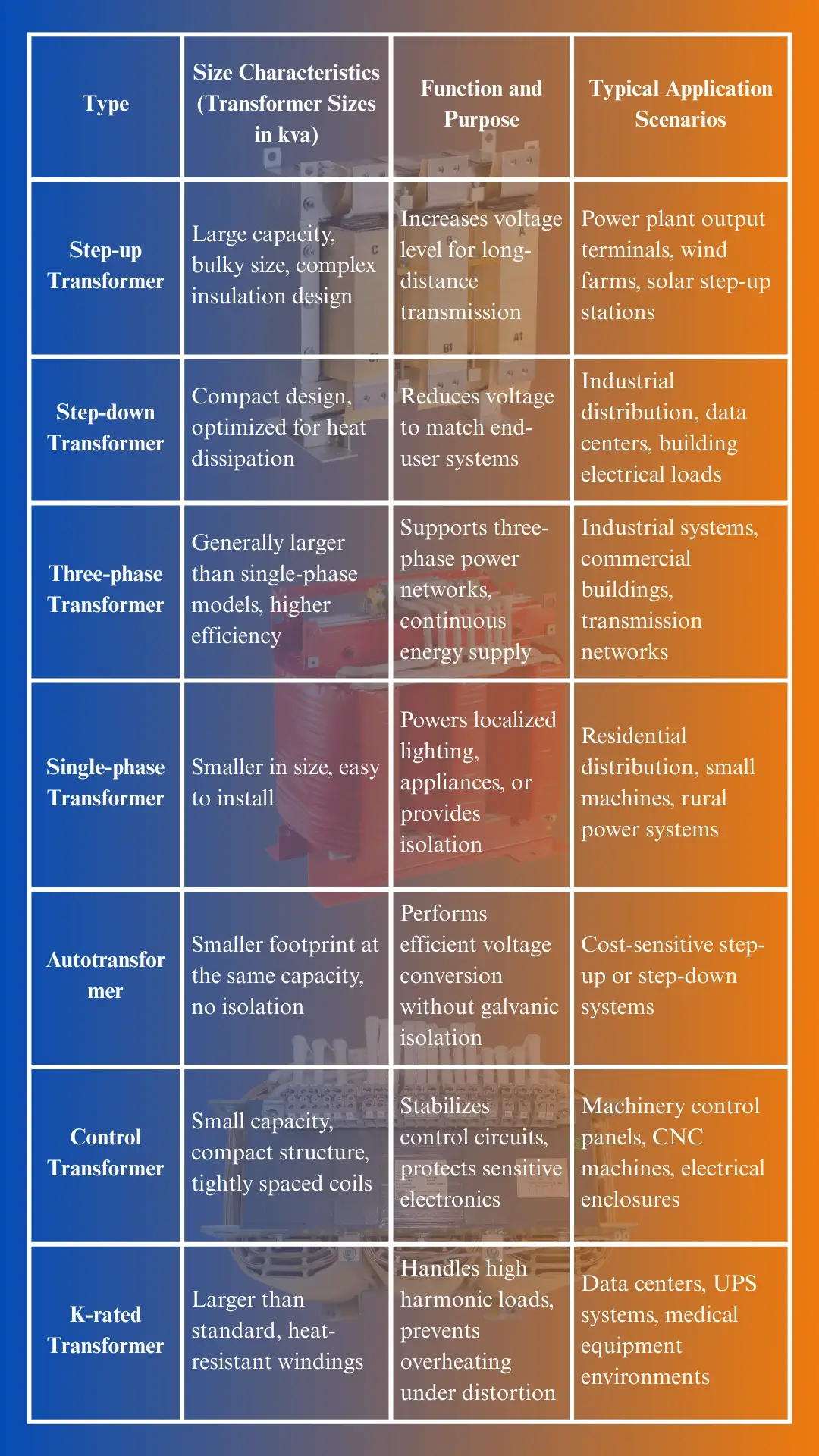

Comparison of common transformer construction types and dimensional characteristics

| Type | Size Characteristics (Transformer Sizes in kva) | Function and Purpose | Typical Application Scenarios |

| Step-up Transformer | Large capacity, bulky size, complex insulation design | Increases voltage level for long-distance transmission | Power plant output terminals, wind farms, solar step-up stations |

| Step-down Transformer | Compact design, optimized for heat dissipation | Reduces voltage to match end-user systems | Industrial distribution, data centers, building electrical loads |

| Three-phase Transformer | Generally larger than single-phase models, higher efficiency | Supports three-phase power networks, continuous energy supply | Industrial systems, commercial buildings, transmission networks |

| Single-phase Transformer | Smaller in size, easy to install | Powers localized lighting, appliances, or provides isolation | Residential distribution, small machines, rural power systems |

| Autotransformer | Smaller footprint at the same capacity, no isolation | Performs efficient voltage conversion without galvanic isolation | Cost-sensitive step-up or step-down systems |

| Control Transformer | Small capacity, compact structure, tightly spaced coils | Stabilizes control circuits, protects sensitive electronics | Machinery control panels, CNC machines, electrical enclosures |

| K-rated Transformer | Larger than standard, heat-resistant windings | Handles high harmonic loads, prevents overheating under distortion | Data centers, UPS systems, medical equipment environments |

P8-transformer dimensions chart

Calculate the appropriate transformer capacity

How to size a transformer? Selection formulas for single-phase and three-phase systems

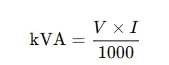

Capacity calculation is the first step when determining transformer size. Basic conversions based on voltage, current and system type (single-phase or three-phase) are required.A low voltage transformer size calculator helps determine the required kVA rating based on load current and voltage.

Single-phase transformer capacity calculation formula:

P9-transformer kva table

where V is the voltage in volts and I is the load current in amps.

Three-phase transformer capacity calculation formula:

P10-3 phase transformer sizing chart

This formula applies to balancing three-phase loads.

Using these two formulas, it is possible to quickly estimate the required capacity rating and then make an initial judgment on the range of transformer size options. The transformer VA rating indicates the maximum apparent power the unit can deliver to the load without overheating.

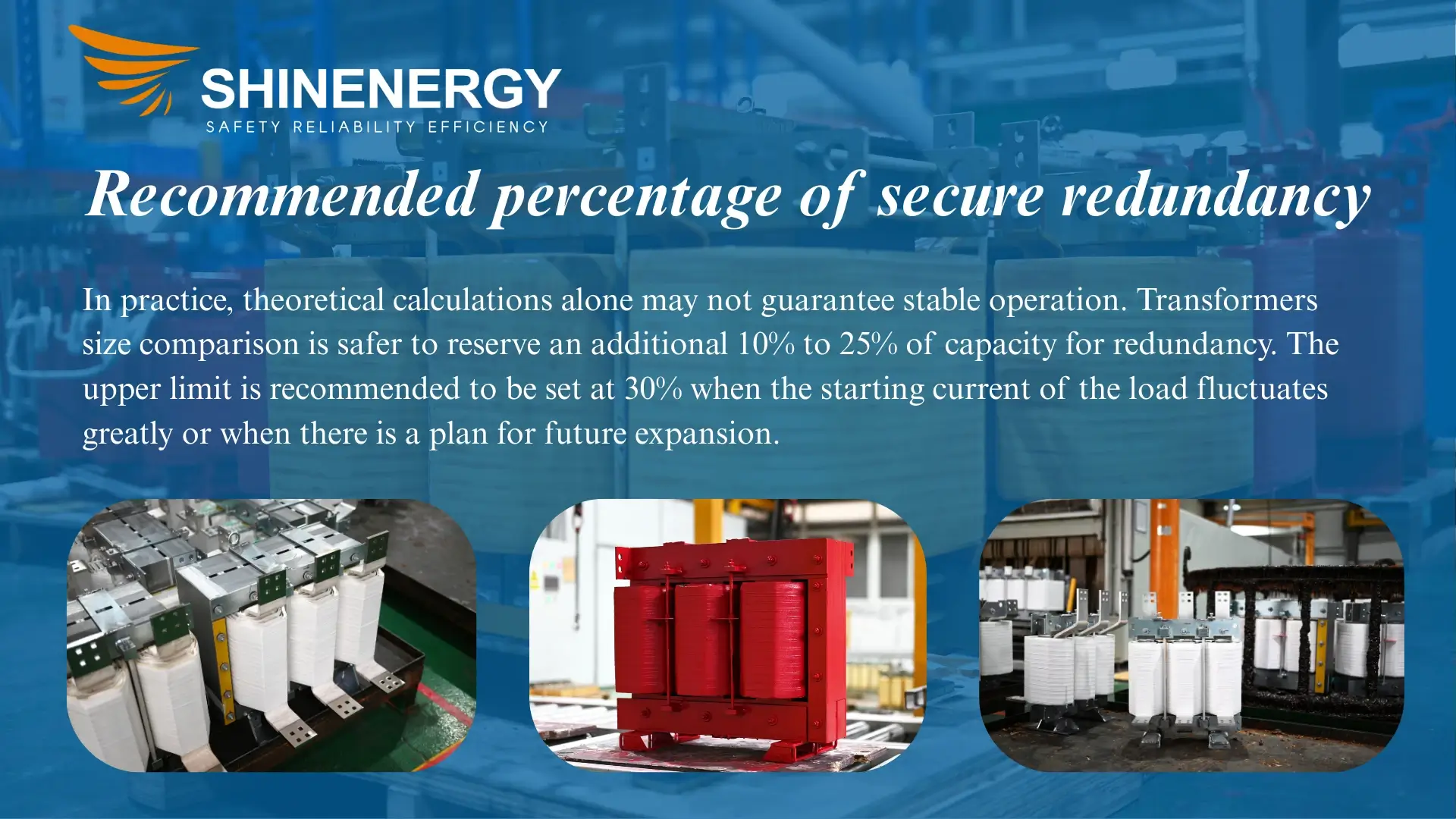

Recommended percentage of secure redundancy

P11-transformer sizing chart 3 phase

In practice, theoretical calculations alone may not guarantee stable operation. Transformers size comparison is safer to reserve an additional 10% to 25% of capacity for redundancy. The upper limit is recommended to be set at 30% when the starting current of the load fluctuates greatly or when there is a plan for future expansion.

Capacity redundancy prevents equipment from operating for long periods of time under high temperatures and high loads, prolongs service life, and reduces the risk of short-term overloads.

How to Select Matching Capacity for a 100A Load?

Assuming a three-phase system with an operating voltage of 400 V and a load current of 100 A, calculate the required transformer capacity:

P12-three phase transformer sizing chart

Combined with the redundancy factor (taken as 25%), the final recommended capacity is:![]()

P13-transformer kva chart

An optional 100 kVA transformer is available. This transformer size allows a margin for future loads and is also suitable for short-term overloads.

Consider the actual installation environment and physical volume

More capacity, more volume? Not necessarily!

3 phase Transformer sizes do not always increase linearly with capacity. While products with higher capacity ratings are typically larger, internal structural design, cooling methods, and insulation requirements also affect form factor.

Certain high-efficiency structures, such as autocoupled designs or low-loss cores, can reduce overall size while maintaining capacity. For actual projects, the transformers length, width and height of the unit should not be judged by kva calculator transformer alone, but rather by the dimensional drawings provided by the manufacturer. Transformers are usually rated in units called kilovolt-amperes (kVA), which represent their apparent power capacity.

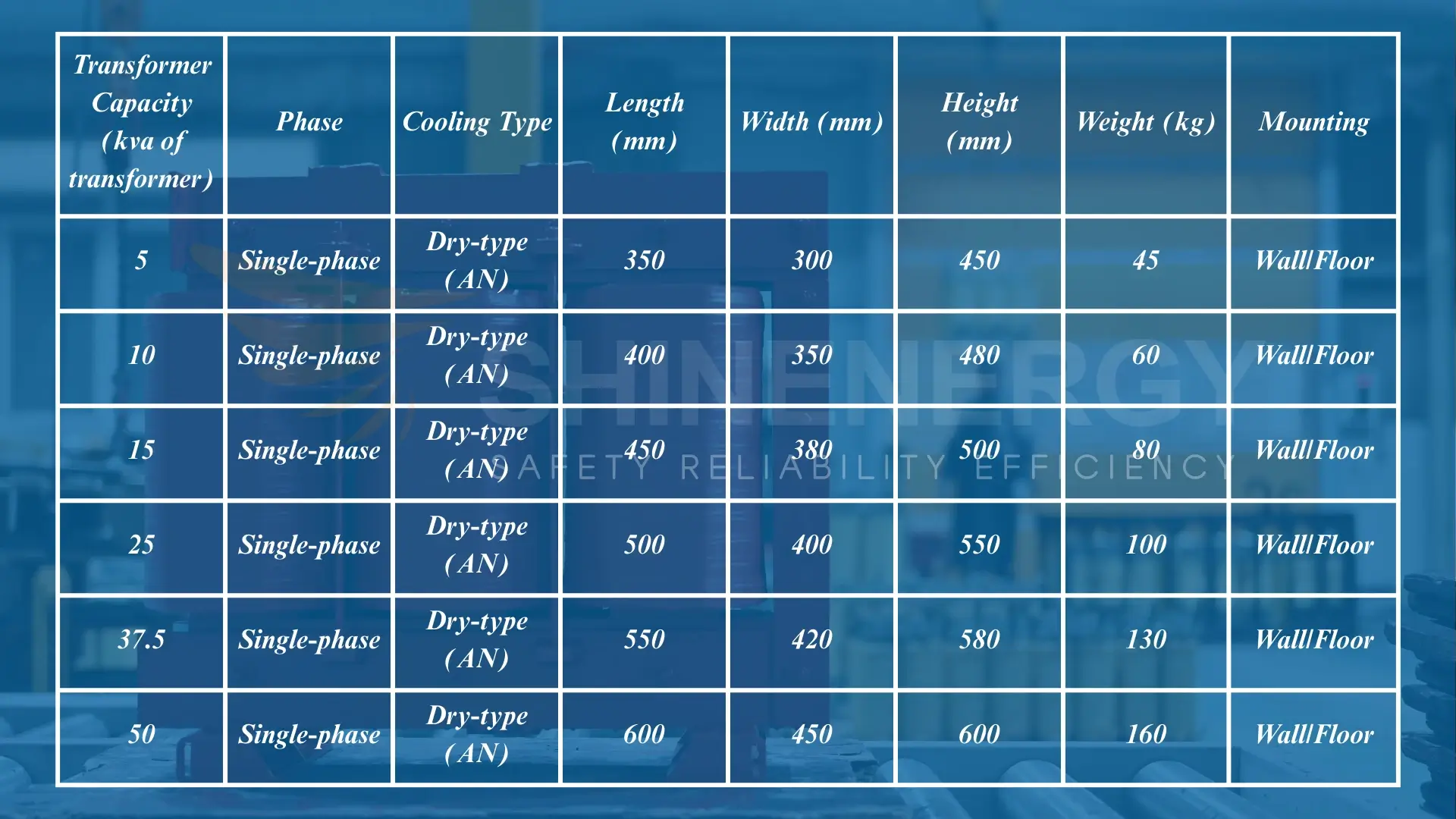

Dry vs. Oil-immersed Differences in Size

Dry-type transformers are naturally cooled by air or forced air-cooled, with large insulation spacing and exposed coils, so the shells are generally larger. For the same transformer capacity, the volume and weight of dry-type products are often higher than oil-immersed.

The oil-immersed structure uses transformer oil to conduct heat, with compact windings, efficient heat dissipation and a smaller footprint. It is suitable for high power density or places with limited installation space. However, because it involves oil circulation, it has higher requirements for fire protection and environmental protection.

| Transformer Capacity (kva of transformer) | Phase | Cooling Type | Length (mm) | Width (mm) | Height (mm) | Weight (kg) | Mounting |

| 5 | Single-phase | Dry-type (AN) | 350 | 300 | 450 | 45 | Wall/Floor |

| 10 | Single-phase | Dry-type (AN) | 400 | 350 | 480 | 60 | Wall/Floor |

| 15 | Single-phase | Dry-type (AN) | 450 | 380 | 500 | 80 | Wall/Floor |

| 25 | Single-phase | Dry-type (AN) | 500 | 400 | 550 | 100 | Wall/Floor |

| 37.5 | Single-phase | Dry-type (AN) | 550 | 420 | 580 | 130 | Wall/Floor |

| 50 | Single-phase | Dry-type (AN) | 600 | 450 | 600 | 160 | Wall/Floor |

P14-type r transformer dimensions chart

Installation constraints: indoor/outdoor, ventilation/transportation/maintenance factors

Indoor installation requires that equipment dimensions be coordinated with switchgear, bus ducts and other systems. Transformers that are too tall or too wide may not fit through doorways or elevators, so measurements must be taken in advance.

Outdoor environments are more concerned with protection ratings and heat dissipation efficiency; IP ratings need to be met for dust and water resistance, and enclosures need to be adequately ventilated or externally ducted.

Transportation constraints also affect the design of transformer size. Some large models need to be transported in sections and assembled on site. Maintenance also requires sufficient space for inspection, dust removal, or component replacement.The transformer volt amp rating defines the maximum apparent power the unit can deliver under full load conditions.

what size transformer do i need? Avoiding Common Size Selection Mistakes

P15- What size transformer do i need

Too large: wasted costs, reduced efficiency

3 phase transformer size chart

Some projects tend to choose high-capacity models for insurance purposes. However, the transformer size chart exceeds the actual load too much, which will lead to the increase of no-load running time and the rise of iron loss. The efficiency of equipment running under low load for a long period of time decreases significantly.

At the same time, the procurement cost of large sizing transformers is higher, the footprint is larger, and the requirements for the installation environment are more stringent. If there is no expansion plan or standby demand, it is not recommended to blindly choose a higher grade transformer specification.

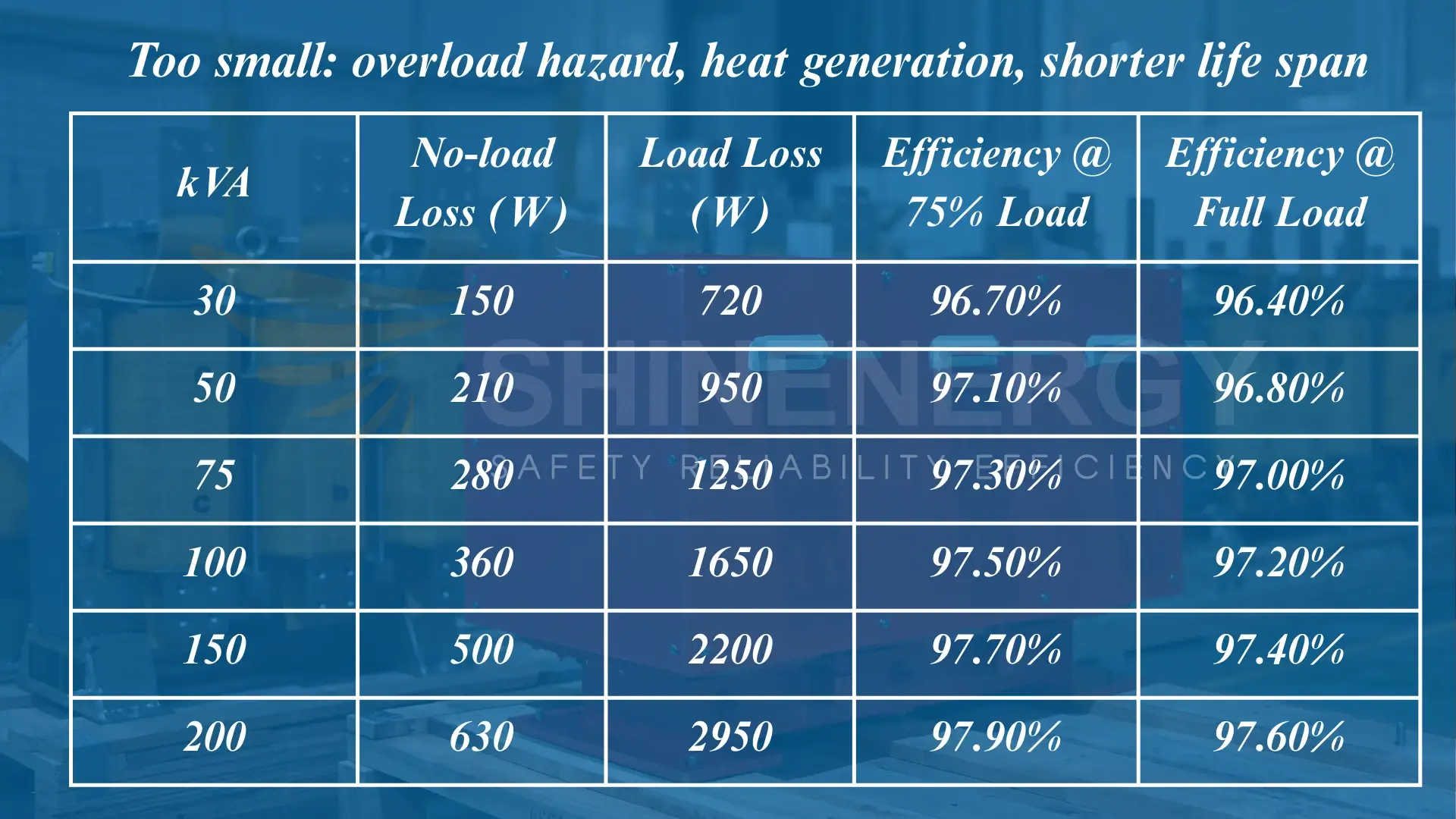

Too small: overload hazard, heat generation, shorter life span

| kVA | No-load Loss (W) | Load Loss (W) | Efficiency @ 75% Load | Efficiency @ Full Load |

| 30 | 150 | 720 | 96.70% | 96.40% |

| 50 | 210 | 950 | 97.10% | 96.80% |

| 75 | 280 | 1250 | 97.30% | 97.00% |

| 100 | 360 | 1650 | 97.50% | 97.20% |

| 150 | 500 | 2200 | 97.70% | 97.40% |

| 200 | 630 | 2950 | 97.90% | 97.60% |

P16- transformer calculation table/kva transformer chart

The problem of insufficient capacity is even more serious. Long-term overload operation will lead to overheating of the winding, insulation aging, and even breakdown failure. If the load current exceeds the rated value by more than 10%, the operating temperature will rise significantly and the life span will be shortened by more than half.

Too small transformer size not only affects the stability of the system, but also increases the maintenance cost and the risk of power outage. Frequent tripping and thermal protection interferes with the entire power supply chain.

Engineers practical advice: how to avoid these “pitfalls”

Calculate the load accurately. Actual load current + safety redundancy is the basis for capacity judgment and should not be estimated.

- Combine with the usage environment. For sites with high room temperature, poor ventilation, and large load fluctuations, it is recommended to float the capacity appropriately.

- Pay attention to later expansion. If the equipment increases in the future, reserve 20% capacity margin to avoid secondary remodeling.

- Check the actual size diagram. Avoid that the transformer size cannot pass through the doorway, elevator or foundation mismatch.

- Communicate the parameters with the manufacturer. Information such as load type, harmonics, operating hours, etc. will help to give an accurate selection program.

- Proper sizing is not about choosing the “biggest”, but the “best”. The right size makes the system stable, economical and sustainable.

Decision making with the help of size charts and manufacturer’s information

Interpretation of common transformer size comparison table

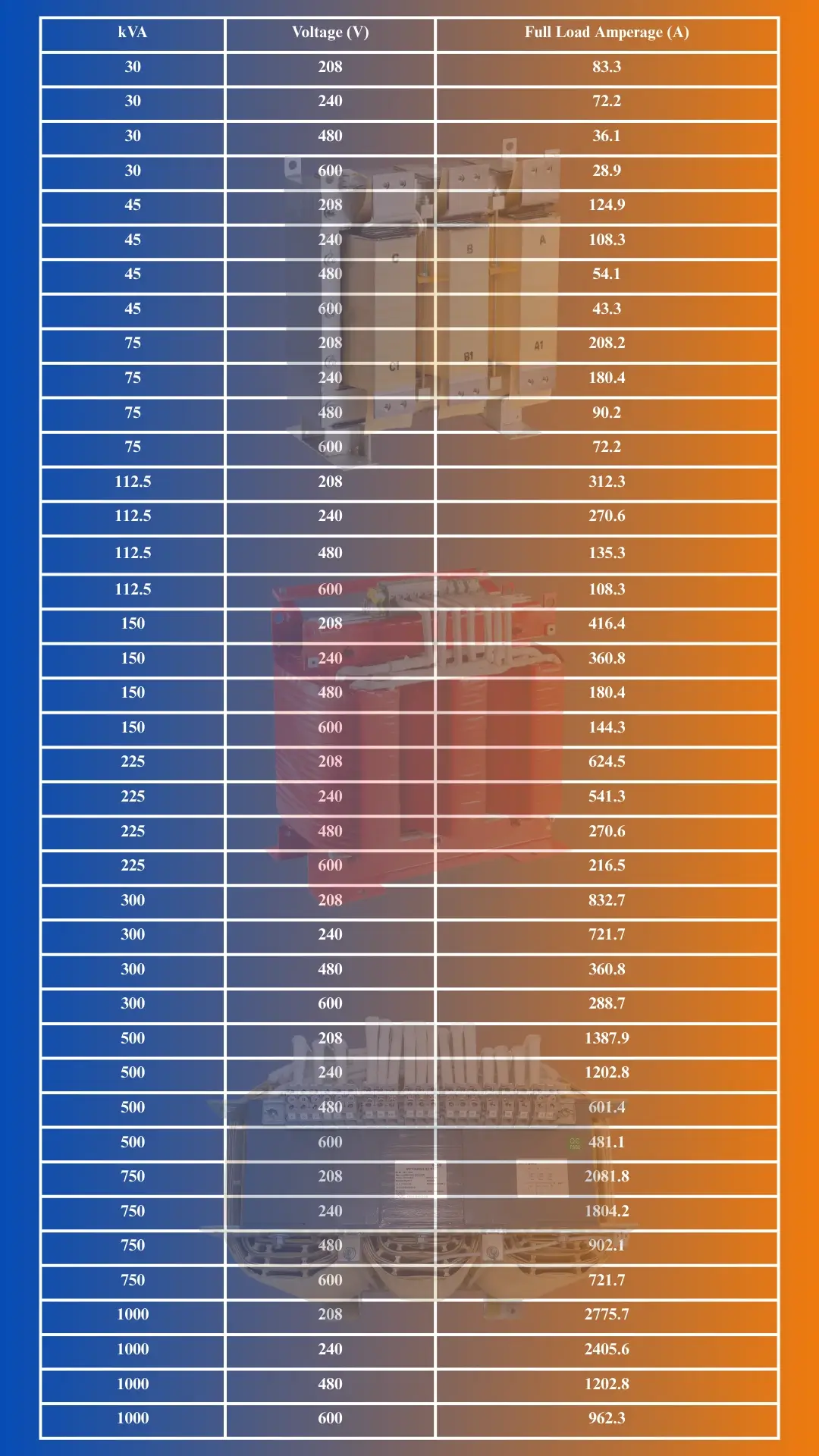

P17- 3 phase transformer kva to amps chart

Manufacturers often provide three phase transformer sizes cross-reference tables that contain core data such as capacity, voltage rating, cooling method, physical dimensions and weight. The comparison table can help you quickly determine if the installation meets your requirements.

When reviewing the transformer kva table, look for the following key fields:

- Rated capacity (kVA): Determines base load capability

- Input/output voltage: Needs to be matched to the on-site power system

- Cooling method: Affects dimensions and operating noise

- Overall dimensions (L x W x H): Determines ease of transportation and installation

- Weight: Checks to make sure that the floor load limitations have not been exceeded

sizing a transformer design varies from manufacturer to manufacturer. Different manufacturers have differences in transformer size design. Different manufacturers vary in transformer size design. The size difference can be more than 10% for the same capacity.

How to Quickly Read a Manufacturer’s Specification Sheet

Every parameter in a transformer specification sheet has practical value. Here are the key elements to focus on:

- Electrical Parameters: Pay attention to frequency, impedance, and insulation class. These determine compatibility with your power system.

- Structural Details: Confirm the wiring configuration, terminal positions, and cooling method.

- Performance Metrics: Evaluate efficiency rating, core and load losses, and noise level to avoid unnecessary energy consumption.

- Certification Standards: Check for compliance with UL, IEC, CE, or other applicable certifications, especially for projects requiring regulatory approval or bidding qualifications.

Do not rely solely on the kVA rating. A complete assessment of transformer size requires considering electrical performance, mechanical layout, and environmental adaptability.

When Should You Consider a Custom Transformer?

Standard models are suitable for most applications. However, custom-built standard size transformersshould be considered in the following situations:

- Transformer sizes Limited installation space — requires reduced height or footprint

- Transformer sizes Non-standard voltage or frequency — incompatible with catalog offerings

- Transformer sizes Special load characteristics — includes harmonic-rich loads, frequent starts/stops, or high inrush current

- Transformer sizes Special protection requirements — such as anti-vibration, corrosion resistance, or explosion-proof design

- Transformer sizes System integration needs — identical dimensions or wiring layout for side-by-side installations

Customized utility transformer sizes improve compatibility with specific site conditions, streamline system layout, and enhance long-term operational reliability.Control transformers are rated in volt-amperes (VA), which indicate the total power available for control circuits.

Seeking Expert Advice for Final Transformer Selection

When Should You Consult a Specialist or Manufacturer?

Not all transformer sizes kva can be determined solely by formulas or sizing charts. In the following scenarios, early consultation with professionals is highly recommended:

- Complex load profiles involving inductive loads, high inrush current, or non-linear loads

- Irregular installation spaces or discrepancies between field measurements and design drawings

- Harsh environments, such as high temperatures, humidity, altitude, or dusty conditions

- Specialized electrical systems involving neutral grounding, specific phase sequence, or unique earthing methods

- Projects requiring international certifications or third-party inspection for bidding or compliance

- The power transformer rating determines the maximum load it can handle without exceeding thermal limits.

Professional guidance can prevent mismatches in transformer size, avoid electrical incompatibilities, and reduce the risk of installation conflicts.

What Information Helps Improve Sizing Accuracy?

Providing the following key details to manufacturers or engineering consultants can significantly enhance rating of transformer recommendations:

Load type and power factor: Motors, capacitors, or lighting systems affect how capacity is calculated

- Voltage levels and wiring configurations: Include input/output voltages and star/delta connections

- Environmental parameters: Ambient temperature, humidity, altitude, and ventilation conditions

- Mounting method: Whether floor-mounted, wall-mounted, enclosed, or mobile

- Future expansion plans: Whether capacity reserves or modular scalability are required

- Lead time requirements: Whether it’s a rush order or standard delivery with stock availability

The more detailed the input, the more precise the standard size of transformer recommendation—and the more tailored the delivery solution.

Standard vs. Custom: How to Choose the Right Fit for Your Project

Standard models offer shorter lead times, lower costs, and complete documentation. They are ideal for typical loads, standard voltage systems, and sites with ample installation space.

Custom-built models provide greater flexibility and are suitable for the following cases:

- Limited installation space

- Non-standard wiring or terminal layouts

- High power density requirements

- Specialized features or certifications (e.g., K-factor rating, anti-vibration, noise suppression)

- System-wide integration where multiple units must match in size and layout

Choosing between standard and custom transformer sizes kva depends on project priorities: Is fast delivery the goal? Or is structural optimization or compliance more critical? Defining these priorities helps you make the right decision.

Summary: Choose the right size and get twice the result with half the effort

The choice of transformer sizes 3 phase has far-reaching consequences. Parameters such as capacity, volume and voltage level not only determine the performance of the equipment itself, but also the operational efficiency and sustainability of the entire system.

- From a technical point of view, size matching guarantees stable voltage and sufficient current. The system runs more efficiently and the equipment lasts longer.

- From the safety point of view, the transformer sizes determine the thermal stability and insulation capacity. Too small is easy to overheat, too big may not be able to install or transport.

- From a cost point of view, a reasonable selection can reduce the initial investment and later maintenance. Reduced losses also reduce the risk of failure.

FAQ

How transformers are rated?

How transformers are rated depends on their ability to handle electrical load under defined operating conditions. Most units are classified based on their apparent power capacity, expressed in kilovolt-amperes (kVA) or megavolt-amperes (MVA). When asking how a transformer is rated, engineers consider several factors, including input/output voltage, frequency, insulation class, and cooling method. For example, a dry-type transformer rated at 150 kVA is designed for continuous operation without exceeding thermal limits at full load. How are transformers rated in practice? Through standardized testing procedures that simulate real-world electrical conditions, ensuring the unit performs safely and efficiently across its intended application range.

What is the 3 phase transformer amperage chart?

A 3-phase transformer amperage chart shows how much current (in amps) a transformer will carry at full load, based on its kVA rating and voltage. It helps users quickly check how much current flows through the system, so they can size wires, breakers, and equipment properly.

How to size a transformer chart?

P18-3 phase transformer amperage chart

What is the current transformer sizing chart?

A Current Transformer (CT) Sizing Chart helps determine the appropriate CT ratio and burden rating based on system current, application type, and metering or protection needs. What transformer do is convert electrical energy from one voltage level to another without changing frequency.

| Primary Current (A) | CT Ratio (Primary:Secondary) | Typical Application | Recommended Accuracy Class | Burden (VA) |

| 50 | 50:05:00 | Small panel metering | 0.5 / 1.0 | 2.5 |

| 100 | 100:05:00 | Residential main switchboard | 0.5 / 1.0 | 5 |

| 200 | 200:05:00 | Light commercial panel | 0.5 / 1.0 | 5 |

| 400 | 400:05:00 | Industrial load centers | 1.0 / 3.0 | 10 |

| 600 | 600:05:00 | Sub-distribution applications | 1.0 / 5.0 | 10 |

| 1000 | 1000:05:00 | Utility & protection circuits | 5.0 / 10P10 | 15 |

The largest Class 2 transformer supplier in North America offers UL-certified models designed for HVAC, lighting, and control circuits.

What is kva on a transformer?

kVA stands for kilovolt-amperes, which is the unit used to rate a transformer’s apparent power capacity. It indicates how much load the transformer can handle safely under full-load conditions. To simplify selection, engineers often use a transformer kVA chart, which lists common kVA ratings alongside their corresponding voltage and amperage values. This helps ensure the transformer matches the actual system requirements. For quicker calculations, a size-a-transformer calculator can be used. By entering load power, voltage, and safety margin, the tool instantly recommends the right transformer size for your application.