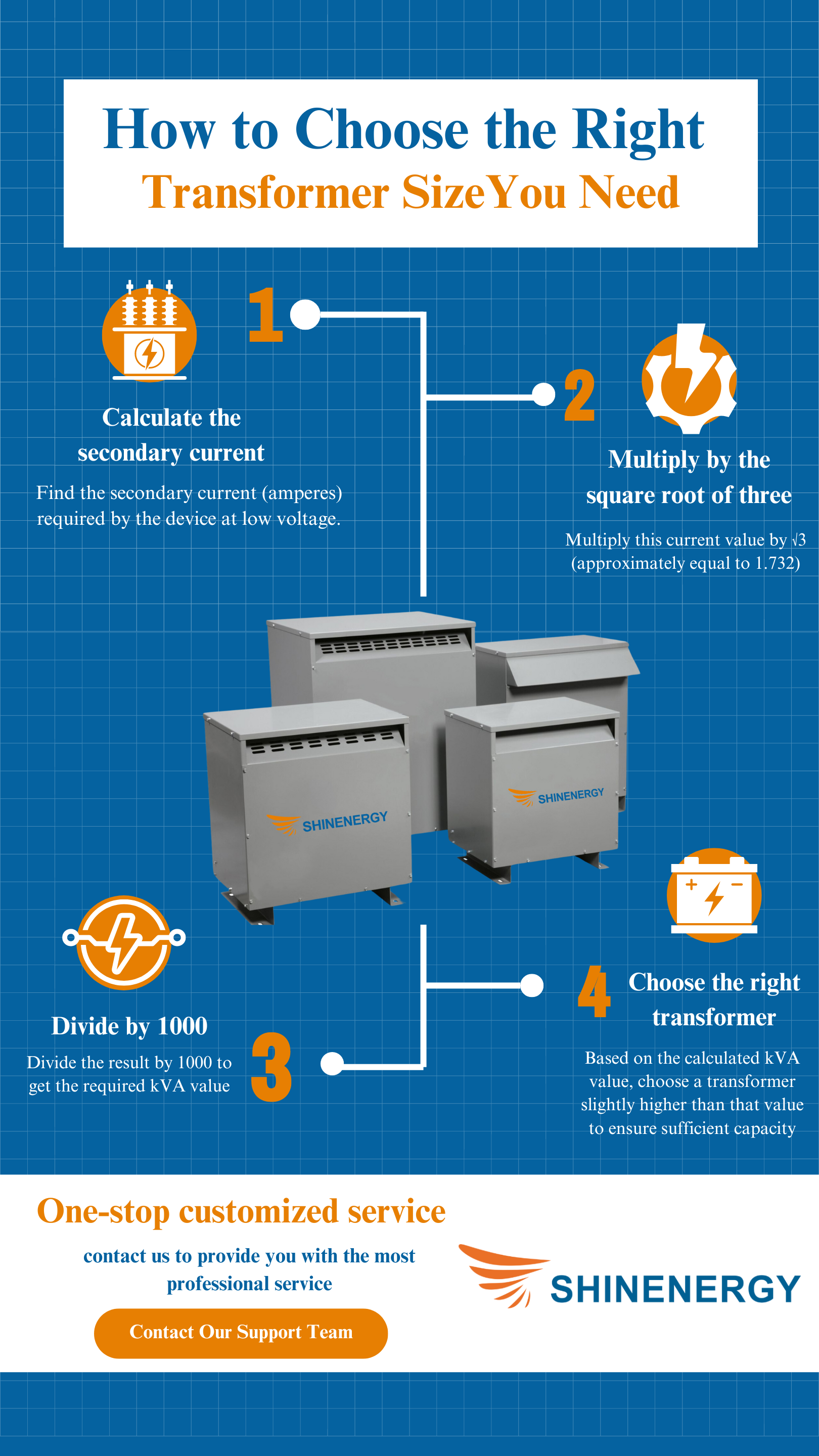

Figure calculate kva

Choosing the right size transformer may sound a little complicated, but it’s actually not that difficult. Whether it’s for home use or industrial needs, finding the right transformer is extremely important because it ensures that your power system operates safely and reliably. In this article, we’ll take a look at what kVA and MVA are, teach you how to calculate these values and help you choose the best transformer size for your needs. Don’t worry, we’ll keep everything simple and clear so you can understand it easily!

Use Our Free Online Calculator

Try our interactive calculator to instantly determine the required transformer size:

👉 Use the Transformer kVA Calculator

What is the kVA rating of a transformer?

Figure 1 defines kva

What are kilovolt amps (kva) and definition of kva? The kVA rating is simply the capacity of the transformer, which indicates the maximum amount of electricity the transformer can handle. In simple terms, kva meaning is short for kilovolt-amperes, which combines two components: voltage and current. Transformers are used to raise and lower voltages. The higher the kVA rating of a transformer, the greater the power demand it can handle. It’s like the horsepower of a car’s engine, the higher the number, the more powerful it is. It’s important to choose a transformer with the right kVA rating to ensure that your equipment can operate normally and not be shut down due to a lack of power. The transformer rating indicates the maximum amount of power it can safely handle, usually measured in kVA or MVA.

Understand transformer sizing

Figure 2-1 how to size a transformer

Choosing the right transformer size is really just about finding out how big it needs to be to meet your power needs. Just like buying clothes, too big or too small is not the right size. The size of the transformer depends on how many devices you will be powering and how much power those devices need. Choosing the wrong size can cause your devices to not work properly or the transformer to overheat. Understanding the basics of load requirements, environmental factors, safety margins, And the transformer equation will help you find the right transformer and ensure it will work safely for a long time.

Standard Transformer Sizes

Figure 3-1 standard size of transformer/ transformer dimensions chart

When choosing a transformer, knowing the common standard sizes can help you make a quick decision. Transformer size is usually expressed in kilovolt-amperes (kVA), which is the amount of power the transformer can provide. Different application scenarios have different requirements for transformers. Here are some common transformer sizes and their typical uses. Transformers in strength order by power strength starting from smaller kVA (kilovolt-amperes), such as 5 kVA household transformers, to larger industrial MVA (megavolt-ampere) transformers, such as 2000 MVA or more.:

Transformer Sizes(kVA) | typical application |

5 kVA transformer | Small appliances, household equipment |

10 kVA transformer | Small office equipment |

15kVA transformer | light industrial equipment |

25 kVA transformer | Medium-sized office equipment, small commercial facilities |

50 kVA transformer | Large commercial equipment |

| 75 kva transformers | factory machinery |

| 100 kVA transformer | Small and medium-sized factories, heavy machinery |

| 150 Kva transformer | Large factory equipment, large data center |

| 300 kVA transformer | Power supply for large industrial equipment and large buildings |

500 kVA transformer | Extra-large factory, widely distributed building system |

750 kVA transformer | Extra large industrial facilities, regional power distribution |

1000 kVA transformer | Super large industrial projects |

| 1500 kva transformer | large power distribution systems |

| 2000 kVA transformer | Large commercial complexes, |

| 2500 kva transformer | large industrial and manufacturing facilities |

| 3000 kVA transformer | Large commercial complexes, large industrial and manufacturing facilities |

Chart 3-2 type r transformer dimensions chart/typical transformer sizes

How to Calculate the kVA Rating of a Transformer

Figure 3-3 volt ampere transformer

Calculating the kVA rating of a transformer is actually quite simple and does not require any complicated math. You just need to know the current (amps) and voltage (volts) that the device requires. For a single-phase transformer, multiply the voltage and current and then divide by 1000 to get the kVA value. The formula is kVA = (voltage x current) / 1000.

To determine the kVA value you need, you will need to do some simple calculations based on the electrical schematic.

First, find the input voltage required by the electrical load on the secondary winding. This is often called the load voltage (V). This voltage value can be found by looking at the electrical schematic. For example, let’s say the load voltage V is 150 volts.

Next, you need to determine the current required by this electrical load. This value can also be found on the electrical schematic. If you don’t have the current value directly, you can calculate it by dividing the input voltage by the input resistance. Let’s say the load current (let’s call it I) is 50 amps.

Once you have these two numbers, you can use them to determine the power requirements of the transformer and calculate the kVA value required. These basic steps will help you accurately select the appropriate transformer size to ensure stable and safe system operation.

How to calculate the Single-Phase kVA Ratings

1 phase transformers use a single phase of AC power and typically have two AC power lines. There are several common types of single-phase transformers, depending on the application scenario and environment:

| Encapsulated transformers | These single-phase transformers are suitable for a variety of general loads, both indoors and outdoors. They are very common in industrial and commercial use, especially in various lighting applications. | If needed, multiple encapsulated transformers can also be combined to form a three-phase transformer. They are generally rated lower, generally between 50 VA and 25 kVA. |

| Ventilated transformers | These single-phase transformers are suitable for a variety of single-phase loads, both indoors and outdoors. | They are often used in commercial and industrial environments, such as lighting systems. Ventilated transformers are generally rated between 25 and 100 kVA. |

| Fully enclosed non-ventilated transformers: | These transformers can be single-phase or three-phase and are particularly suitable for use in environments with a lot of dust and debris. | They are generally rated between 25 and 500 kVA. |

Chart 3-4 transformer sizing chart

Let’s say your device operates on 240 volts and requires 20 amps of current. You can calculate kVA like this:

transformer formula: kVA = (voltage x current) / 1000

Calculation: kVA = (240 x 20) / 1000 = 4.8 kVA

How to calculate the Three-Phase kVA Ratings

There are several different types of 3 phase transformers, which typically have three power lines that are 120 degrees out of phase with each other. You can use a kVA calculator for 3 phase systems to quickly determine the required transformer size based on voltage and current.

Compared to single phase transformers, three phase transformers also have similar types:

| Enclosed transformers | This type of three-phase enclosed transformer is suitable for a variety of general loads, both indoor and outdoor commercial and industrial applications, | including systems used for lighting. These transformers are generally rated between 3 and 75 kVA.

|

| Ventilated transformers | Three-phase ventilated transformers are suitable for a variety of general indoor and outdoor loads and are widely used in industrial and commercial fields, | including lighting purposes. They have a wide range of power ratings, up to 1000 kVA. |

| Fully enclosed non-ventilated transformers | Similar to the single-phase versions, these three-phase transformers are ideal for use in environments with a lot of dust and debris. | They are generally rated between 25 and 500 kVA.

|

Chart 3-5 transformers size chart

For three-phase transformers, there is a slight extra step: multiply the current and voltage, then multiply by 1.732 (which is √3), and finally divide by 1000. The formula is: kVA = (1.732 x voltage x current) / 1000. Follow these steps and you will be able to figure out how big a transformer you need. Calculating amps on 3-phase requires using the formula: Amps = (kVA × 1000) / (√3 × Voltage).

Power 3 Phase Calculation

Let’s say your device runs on 415 volts and requires 30 amps.

The calculation is slightly more one step:

- Formula: kVA = (1.732 x voltage x current) / 1000

- Calculation: kVA = (1.732 x 415 x 30) / 1000 = 21.54 kVA

Follow these steps and you will be able to figure out how big a transformer you need. This will ensure that your transformer is adequate and your device will work properly.

How to size a transformer: Steps to determine the appropriate transformer sizing

Step 1: Calculate Load Requirements

Figure 4-1 how to find kva

How to check transformer Load Requirements? First, you need to know how much power your device or system requires. Let’s say you have a device that says on its label that it requires 240 volts and 10 amps. You can calculate the power requirement by simply multiplying the voltage by the current: 240 volts x 10 amps = 2400 watts (or 2.4 kilowatts). If you have multiple devices, add up the wattage of each device to get the total power requirement.

Example: If you have three devices with power requirements of 2.4 kW, 3.6 kW, and 1.2 kW, the total requirement is 2.4 + 3.6 + 1.2 = 7.2 kW.

Step 2: Understand the load characteristics

Figure 4-2 Transformer rating

Next, figure out what type of load you have. Different devices have different power requirements, for example, some devices need a steady current, while devices such as motors require a higher current when starting. If you have a lot of motor devices, you need to consider these starting currents.

Example: Suppose you have a motor whose starting current is three times the normal operating current. When choosing a transformer, you need to make sure the transformer can withstand this instantaneous high current, not just the current when the motor is running normally.

Step 3: Add a safety margin

Figure 4-3 volt transformer

After determining the basic requirements, it is recommended to add a safety margin. This margin is usually to cope with future expansion or unexpected power requirements. For example, you can add a 20% margin to your total power requirements in case new equipment is added in the future or the power demand exceeds expectations.

Example: If your total power requirement is 7.2 kW, after adding a 20% safety margin, the total power you need becomes 7.2 kW x 1.2 = 8.64 kW.

Step 4: Consider environmental conditions

Figure 4-4 Transformer equation

Don’t forget to consider the environment in which the transformer will be used. Factors such as temperature, humidity, and dust can affect the performance of the transformer. If the transformer is to be placed in a very hot place, or in a workshop with a lot of dust, you need a transformer that can operate stably under such conditions.

Example: Suppose your transformer is to be installed in an outdoor factory where the temperature is very high in the summer and there is a lot of dust. You may need a fully enclosed transformer that prevents dust from entering and can withstand high temperatures.

Step 5: Choose the right transformer

Figure 4-5 Transformer formula

Finally, use all the information you calculated to choose a suitable transformer. You need to find a transformer with a slightly higher power rating than your calculations to ensure that you have enough power but also avoid unnecessary waste.

Example: If your final total power requirement is 8.64 kilowatts, you can choose a 10 kVA (kilovolt-ampere) transformer so that there is enough margin to handle the load without overloading it.

By following these steps and referring to these examples, you can choose a suitable transformer to ensure the stable and safe operation of your equipment.

Common mistakes when selecting a transformer

When choosing a transformer, common mistakes can sometimes lead to unstable operation or damage to equipment. Here are some common mistakes and suggestions on how to avoid them, with specific examples attached at each step to help you better understand:

Mistake 1: Underestimating load requirements

Figure 5-1 amperage to kva

Sometimes, we may underestimate the total power requirements of the equipment and choose a transformer that is too small. As a result, the transformer may be overloaded during use, causing heating or damage.

Example: Suppose you have several devices that require 15 kVA of power together, but you only choose a 10 kVA transformer. As a result, the transformer is always overloaded and will soon fail, which may even cause safety issues.

Mistake 2: Ignoring load characteristics

Figure 5-2 kva a amp

Different types of equipment have different power requirements, and some equipment requires a much higher current at startup than during normal operation. If you do not consider these load characteristics and choose an inappropriate transformer, the equipment may have problems when starting.

Example: Suppose you have a high-power motor whose starting current is four times the running current. If you only consider the running current when selecting a transformer and do not consider the starting current, the transformer may not provide enough power when the motor starts, causing the motor to fail to start normally.

Mistake 3: Ignoring environmental conditions

Figure 5-3 kva in ampere

The working environment of the transformer is also very important. If the special requirements of the transformer environment, such as temperature, humidity, dust and other conditions, are ignored, it may cause the transformer to have unstable performance or premature damage in actual use.

Example: If the transformer you choose is to be installed in a very humid place, but you choose an ordinary ventilated transformer, the result may be that the internal circuit of the transformer is short-circuited due to the influence of moisture, causing the transformer to fail. The 50 kVA transformer max current for single phase can be calculated based on the voltage supplied.

Mistake 4: Not considering future expansion

Figure 5-4 480 voltage power and current formula

It is also a common mistake to not consider the possible increase in equipment or power requirements in the future when selecting a transformer. The result of this is that once new equipment is added, the original transformer may not be enough and needs to be replaced with a larger one, causing unnecessary trouble and cost.

Example: Your current equipment requires 20 kVA of power, and you choose a transformer that is exactly 20 kVA. Later, you added some new equipment and the total power demand increased to 30 kVA. As a result, you have to buy a larger transformer again, adding additional expenses.

By avoiding these common mistakes and referring to the examples above, you can better choose the right transformer to ensure the stable and safe operation of your equipment.

Practical Example of Transformer Sizes

When selecting transformer size, practical examples can help us better understand how to apply these principles and steps. Below are several practical examples of transformer size selection to help you master how to choose the right transformer for different application scenarios:

Example 1: Outdoor Industrial Equipment Application

Figure 6-1 Residential transformer

Suppose you need to select a transformer for a group of outdoor industrial equipment, which is located in a dusty and humid environment. The total power demand of the equipment is 40 kW, and the environmental conditions are relatively harsh, so the transformer needs to have good protection performance. We need to install transformers to ensure a stable power supply for the building.

Steps:

- Calculate the total power demand: 40 kW.

- Consider the environmental conditions: Because the environment is dusty and humid, you need to select a fully enclosed non-ventilated transformer to prevent dust and moisture from entering.

- Add a safety margin: Considering future expansion and long-term reliable operation of the equipment, you decide to add a 20% safety margin, 40 kW x 1.2 = 48 kW.

- Select a transformer: Select a 50 kVA fully enclosed non-ventilated three-phase transformer, which can ensure that the transformer can operate stably in harsh environments.

Example 2: Photovoltaic Energy Storage System

Figure 6-2 turn kw into amps

Suppose you are selecting a transformer for a photovoltaic energy storage system. This system needs to convert the DC power generated by the solar panels into AC power, which is then stored in the battery or directly supplied to the user. The total power requirement of the system is 80 kW, and you also need to consider the efficiency of the inverter and the possibility of future system expansion.

Steps:

- Calculate the total power requirement: 80 kW.

- Consider the system efficiency: Assume that the inverter efficiency is 90%, and you need to consider this efficiency loss. The actual power required = 80 kW / 0.9 = 88.89 kW.

- Add a safety margin: Add a 10% safety margin for possible future expansion, 88.89 kW x 1.1 = 97.78 kW.

- Choose a transformer: Choose a 100 kVA three-phase transformer, which can ensure that the transformer can still provide stable power when the photovoltaic system is expanded and under high load.

Example 3: Data Center

Figure 6-3 3 phase to single phase transformer

Suppose you are selecting a transformer for a data center. Data centers usually have a large number of servers and related equipment, and the demand for electricity is very high and very stable. Assume that the total power demand of this data center is 500 kW, and you also need to consider the power demand of the uninterruptible power supply (UPS) and cooling system.

Steps:

- Calculate the total power demand: 500 kW.

- Consider other equipment requirements: Assume that the UPS and cooling system require an additional 100 kW, the total demand becomes 600 kW.

- Add a safety margin: Considering possible future expansion and redundant design, add a 20% safety margin, 600 kW x 1.2 = 720 kW.

- Choose a transformer: Choose a 750 kVA three-phase transformer, which can ensure that the data center still has enough power supply when all equipment is running at full load.

Example 4: Medical Facility

Figure 6-4 va transformer

Suppose you are selecting a transformer for a hospital. Hospital equipment has very high power requirements and must be very reliable. Any power outage can lead to serious consequences. Assume that the total power demand of the hospital is 250 kW, including operating room equipment, MRI scanners, X-ray machines, and other important life support systems.

Steps:

- Calculate the total power demand: 250 kW.

- Consider equipment characteristics: Some medical equipment, such as MRI scanners, may require higher currents when starting, so consider the high starting currents of these devices.

- Add a safety margin: To ensure power supply stability in emergencies and possible addition of new equipment, add a 25% safety margin, 250 kW x 1.25 = 312.5 kW.

- Select a transformer: Select a 350 kVA three-phase transformer, which can not only meet the needs of existing equipment but also cope with emergency and future expansion power needs.

These examples show how to select the appropriate transformer size according to different application scenarios. Whether it is a photovoltaic energy storage system, a data center, or a medical facility, the key is to accurately calculate the total power demand, consider equipment characteristics and environmental conditions, and add appropriate safety margins for future expansion. This ensures that the selected transformer is both cost-effective and meets the requirements of a reliable power supply.

What is the Start Factor?

Figure 6-5 3 phase to 1 phase transformer

Starting equipment often requires more current than it does during normal operation. To account for this additional current demand, it is helpful to include a starting factor when calculating the transformer’s kVA. A common rule of thumb is to multiply the voltage by the current and then multiply by an additional starting factor, such as 125%. In practice, this is equivalent to dividing the power factor of 0.8 by 1.25.

However, if you start the transformer frequently (such as more than once per hour), then you may need a higher kVA value than this calculation suggests. If you are working with special loads, such as large motors or medical equipment, your kVA requirements may be different. In these cases, it is best to consult us for appropriate kVA recommendations.

How to Convert Kilowatts to kVA?

Figure 7-1 convert kva to amps per phase

To convert kilowatts to kilovolt-amperes, you need to divide by 0.8, which is the typical power factor for the load. Let’s say you know your transformer runs at 6 kW. Here’s the formula:

kVA=6 kW/0.8

In this example, you divide 6 by 0.8, which gives you 7.5 kVA. However, when you’re choosing a transformer, you won’t find one rated at 7.5 kVA. Most transformers have kVA ratings in whole numbers, many in multiples of 5 or 10, like 10 kVA, 50 kVA, 100 kVA, etc. Therefore, in most cases, you’ll want to choose a transformer rated slightly higher than the kVA you calculated – in this case, probably 10 kVA. You can also use the KVA calculator and transformer calculator. The relationship between kVA and amps is that kVA indicates the power capacity of the transformer, while amps indicate the strength of the current, and the two combined can determine the power requirements of the equipment.

How Do You Figure Amperage and Ampere Convert to kVA?

Figure 8 amps convert to kva

You can also work backward and use the known kVA rating of the transformer to calculate the current (amperes) of a three-phase transformer:

I = (kVA x 1,000 volts) ÷ 1.732 (square root of 3)

Suppose your transformer is rated for 2 kVA and you want it to run at 30 volts, you would multiply 2 by 1,000 to get 2,000, and then divide 2,000 by 30 to get 66.67. Finally, divide 66.67 by the square root of 3 (1.732), which is 38.5 amps. So, your transformer can run at a maximum current of about 39 amps.

If calculating kVA is a little cumbersome or you don’t feel like doing the math, use a chart. Many manufacturers provide charts that make it easier to determine the correct kVA value. To use a chart, you simply find the intersection of the corresponding voltage and current values on the chart to find the kVA value you need.

Single Phase (240V) Transformer Amperage

| 1kva transformer amperage(amps) | 4.17 A |

| 10 kva transformer amperage(amps) | 41.67 A |

15 kva transformer amperage(amps) | 62.50 A |

25 kva transformer amperage(amps) | 104.17 A |

| 30 kva transformer amperage(amps) | 125.00 A |

| 35 kva transformer amperage(amps) | 145.83 A |

| 40 kva transformer amperage(amps) | 166.67 A |

| 45 kva transformer amperage(amps) | 187.50 A |

| 50 kva transformer amperage(amps) | 208.33 A |

| 75 kva transformer amperage(amps) | 312.50 A |

| 112.5 kva transformer amperage(amps) | 468.75 A |

| 150 kva transformer amperage(amps) | 625.00 A |

| 400 kva transformer amperage(amps) | 1666.67 A |

| 500 kva transformer amperage(amps) | 2083.33 A |

3000 kva transformer amperage(amps) | 12500.00 A |

transformer kva/ transformer amp chart

Three Phase (480V) Transformer Amperage

| 1kva transformer dimensions | 1.20 A |

| 10 kva transformer dimensions | 12.02 A |

| 15 kva transformer dimensions | 18.03 A |

| 25 kva transformer dimensions | 30.05 A |

| 30 kva transformer dimensions | 36.06 A |

| 35 kva transformer dimensions | 42.07 A |

| 40 kva transformer dimensions | 48.08 A |

| 45 kva transformer dimensions | 54.09 A |

| 50 kva transformer dimensions | 60.10 A |

| 75 kva transformer dimensions | 90.15 A |

| 112.5 kva transformer dimensions | 135.22 A |

| 150 kva transformer dimensions | 180.23 A |

| 400 kva transformer dimensions | 480.54 A |

| 500 kva transformer dimensions | 600.68 A |

| 3000 kva transformer dimensions | 604.08 A |

transformer amperage chart

How to calculate MVA?

Figure 9-1 va mva

When selecting and using transformers, we often hear the terms kVA and MVA. Although they are both used to measure the power capacity of a transformer, they actually represent different power levels. kVA, kilovolt-ampere, is a unit of power commonly used for small and medium-sized transformers, suitable for smaller power needs. MVA, megavolt-ampere, is used for larger transformers, usually used in industrial facilities and large power distribution systems.

What is MVA?

Figure 9-2 define mva

MVA is actually “Megavolt-Ampere”, which is used to express the power capacity of a transformer or other power equipment. In simple terms, MVA is a larger unit used to describe the amount of power a device can handle. When we say that a transformer has a capacity of 1 MVA, it means that it can handle 1000 kVA of power, which is suitable for large factories, power plants, or buildings that need a lot of power. In contrast, kVA is “Kilovolt-Ampere”, which is a smaller unit of MVA and is used to describe smaller power needs. So, if you see the unit MVA, know that it is used to describe larger power systems!

How to Convert kVA to MVA?

Figure 9-3 MVA and mw

Converting kVA to MVA is actually very simple because they are related just like kilograms and tons. 1 MVA is equal to 1000 kVA. To convert kVA to MVA, you just need to divide the kVA value by 1000.

Mva to kW conversion: you just multiply the MVA value by 1000 and by the power factor (usually 0.8). The formula is: kW = MVA x 1000 x power factor.

For example, if you have 2000 kVA and you want to know how many MVA it is equivalent to, divide 2000 by 1000 and you get 2 MVA. Therefore, 2000 kVA is 2 MVA. Remember this simple conversion method, and you can easily convert between kVA and MVA!

How to Calculate MVA?

Figure 9-4 convert kva to amp

Calculating MVA is actually quite simple. It is used to calculate the power of a transformer or power device. MVA stands for Megavolt-Ampere and is a measure of the maximum amount of power a device can handle.

To calculate MVA, you need to know the voltage (expressed in kilovolts, kV) and the current (expressed in amperes, A). The formula is simply to multiply the voltage by the current and divide by 1000.

For example, if you have a device that has a voltage of 10 kilovolts and a current of 100 amperes, the calculation for MVA is:

MVA=10 kV×100 A/1000=1 MVA

So, a device with 10 kilovolts and 100 amperes has a capacity of 1 MVA. Remember, just multiply the voltage by the current and divide by 1000 to easily calculate MVA!

How to determine the load voltage?

Figure 10 how to calculate load of transformer

Generally, the required voltage will be indicated on the nameplate or manual of the equipment. For example, household appliances usually require 220 volts, while industrial equipment may require higher voltages, such as 380 volts or higher. The transformer on load is supplying power to the connected devices.

If you are not sure about the load voltage of the equipment, you can check the electrical schematic or equipment label, which usually clearly states the voltage value required by the equipment. If the voltage requirements of the equipment are inconsistent with the voltage of your power supply system, you may need to use a transformer to adjust the voltage.

In general, the key to finding the load voltage is to check the markings on the equipment to confirm the voltage they require, and then make sure your power system can provide this voltage. In this way, the equipment can operate normally and safely!

How to determine the secondary voltage?

Figure 11 transformer primary and secondary

Determining the secondary voltage is actually quite simple. It mainly depends on the voltage output of the transformer, which is the voltage at which the transformer delivers power to the device. The secondary voltage is the output voltage of the transformer, which is directly related to the operating voltage of the device.

To determine the secondary voltage, you can check the nameplate or manual of the transformer, which usually indicates its secondary voltage. For example, some transformers may have a secondary voltage of 24 volts, which is used to power some small devices, while other transformers may have a secondary voltage of 220 volts, which is used to power household appliances or industrial equipment.

If you have a transformer specification sheet or wiring diagram, you can also find the secondary voltage information from it. As long as you make sure the transformer’s output voltage matches your device’s needs, you can make the device run properly and safely! So, to understand the secondary voltage, it is mainly to find out the output specifications of the transformer.

How to determine the primary voltage?

Figure 12 kva amperes

Determining the primary voltage is pretty simple. This is the voltage that the transformer receives from the grid or power source. The primary voltage determines the type and size of power the transformer needs, so it’s important to know this.

To find the primary voltage, you can look at the nameplate or manual of the transformer, which usually states what the transformer’s input voltage is. For example, some transformers have a primary voltage of 110 volts, which is standard voltage in North America, while others have a primary voltage of 220 volts, which is standard voltage in other countries or regions.

If you have a data sheet or wiring diagram for the transformer, you can also find information about the primary voltage there. The key is to make sure your power source can provide the primary voltage that the transformer needs so that the transformer can work properly. As long as you know the input voltage requirements of the transformer, you will be able to install and operate the equipment smoothly!

Conclusion

To sum up, choosing and using a transformer is not as complicated as you think. The key is to figure out your power needs, including the voltage and current your equipment needs, and then choose an appropriate transformer based on this information. Don’t forget to consider environmental conditions and possible future power increases so that the transformer you choose can work more safely and stably.

Whether it’s determining the primary voltage, and secondary voltage, or calculating kVA and MVA, just follow these simple steps and you will be able to do it easily. If there are some areas that you are not sure about, don’t be afraid to ask an expert to make sure that the transformer you choose is exactly what you need. This way, your equipment will always run stably and you will save a lot of trouble!

FAQ

What does VA stand for?

VA stands for Volt-Ampere, a unit used to measure apparent power in an electrical circuit.

How is amperage divided in a 3-phase circuit breaker?

In a 3-phase circuit breaker, the total amperage is evenly divided across the three phases, each carrying one-third of the total current.

How much electricity does a high-voltage transformer produce?

A transformer doesn’t produce electricity; it transforms voltage levels. The amount it handles depends on its rating, which could range from a few kVA to several hundred MVA.

How much electricity does a high-voltage transformer use?

High-voltage transformers use electricity proportional to the load they are supplying, as well as a small amount of energy lost as heat.

What is a kVA?

kVA stands for kilovolt-ampere, a unit that measures apparent power in a transformer or electrical system.

What does a transformer do?

A transformer changes the voltage level of electricity, either stepping it up (increasing) or stepping it down (decreasing), for safe and efficient power distribution.

How to figure out amperage?

Amperage can be calculated using the formula: Amps = Power (Watts) / Voltage (Volts).

What does VA stand for in electrical?

In electrical terms, VA stands for Volt-Ampere, which measures apparent power in an AC circuit.

What does kVA stand for?

kVA stands for kilovolt-ampere, a unit that represents 1,000 Volt-Amperes, used to measure apparent power in electrical systems.

How many types of transformers are there?

There are several types, including step-up, step-down, isolation, autotransformers, and instrument transformers, among others.

How to calculate the number of turns in a transformer?

The number of turns in a transformer can be calculated using the formula: Turns ratio = Primary Voltage / Secondary Voltage. This gives the ratio between the number of turns in the primary and secondary windings.

Pingback: What are the main parts of a power transformer? - Voltori Transformer | Powering Canada with Precision & Performance

Pingback: How to Size Transformers for Canadian Residential Voltage (120V/240V)? - Voltori Transformer | Powering Canada with Precision & Performance