What does a transformer do? A transformer nameplate provides essential information. It helps engineers, buyers, and technicians understand key transformer specifications. Voltage, power rating, frequency, and impedance are all listed. This data ensures proper selection, installation, and maintenance.

Misreading a nameplate can lead to serious issues. Overloading, incorrect wiring, or inefficient performance may occur. Understanding each parameter prevents these mistakes.

This guide explains how to read a transformer nameplate. It covers key terms, real-world examples, and common errors. By the end, you will know how to use nameplate data effectively.

Figure 1-1 Transformer Nameplate

What is this transformer Nameplate and Why Is It Important?

Definition of a Transformer Nameplate

Figure 1-2 definition of nameplate

A transformer nameplate is a metal tag attached to the unit. It contains key electrical and mechanical details. Voltage, power rating, frequency, and impedance appear on it.

Manufacturers include this information for identification and operation. Engineers, buyers, and technicians use it for selection and maintenance.

Nameplates follow industry standards. IEC, ANSI, and IEEE set guidelines for content and format. These standards ensure accuracy and consistency.

Without a nameplate, identifying transformer specifications becomes difficult. Proper installation and safe operation rely on this data.

The Role of a Transformer Nameplate

Figure 1-3 transformer diagram/transformer symbol

A transformer name plate provides essential details. It helps engineers, buyers, and technicians identify key transformer specifications.Transformer abbreviation varies based on type and function, such as HV for high voltage, LV for low voltage, and kVA for power capacity.

Transformer Nameplate: Ensures Proper

Figure 1-4 electrical symbol for transformer

The nameplate shows voltage, kVA, and frequency. Engineers use this data to choose the right transformer meaning for a system. Transformer and types vary based on design, function, and application.

Transformer Nameplate: Supports Safe Installation

Figure 1-5 transformer electrical symbol

Voltage ratings and wiring configurations prevent transformer connections errors. Proper installation reduces the risk of damage or failure. Transformer and its types serve different purposes in electrical systems. Primary transformer windings are labeled with the letter H to indicate high voltage connections.

Transformer Nameplate: Aids Maintenance and Troubleshooting

Figure 1-6 symbol for transformer electrical

Technicians check impedance, cooling type, and temperature rise. This information helps diagnose issues and plan maintenance. Wiring transformers requires proper terminal identification, correct voltage connections, and adherence to safety guidelines.

Transformer Nameplate: Ensures Compliance with Standards

Figure 1-7 electrical transformer symbol

IEC, ANSI, and IEEE define nameplate requirements. Following these standards ensures safety and reliability.

Different kinds of transformers have distinct nameplates. High voltage transformers display high voltage transformer ratings and cooling methods. Distribution transformers list primary and secondary voltages for grid connections. Dry-type transformers highlight insulation class and temperature rise. Autotransformers show single-winding voltage ratios. Special-purpose transformers include custom transformer specifications for unique applications.

Key Parameters on a Transformer Nameplate

A transformer nameplate contains important technical details. Each parameter affects performance, safety, and compatibility.

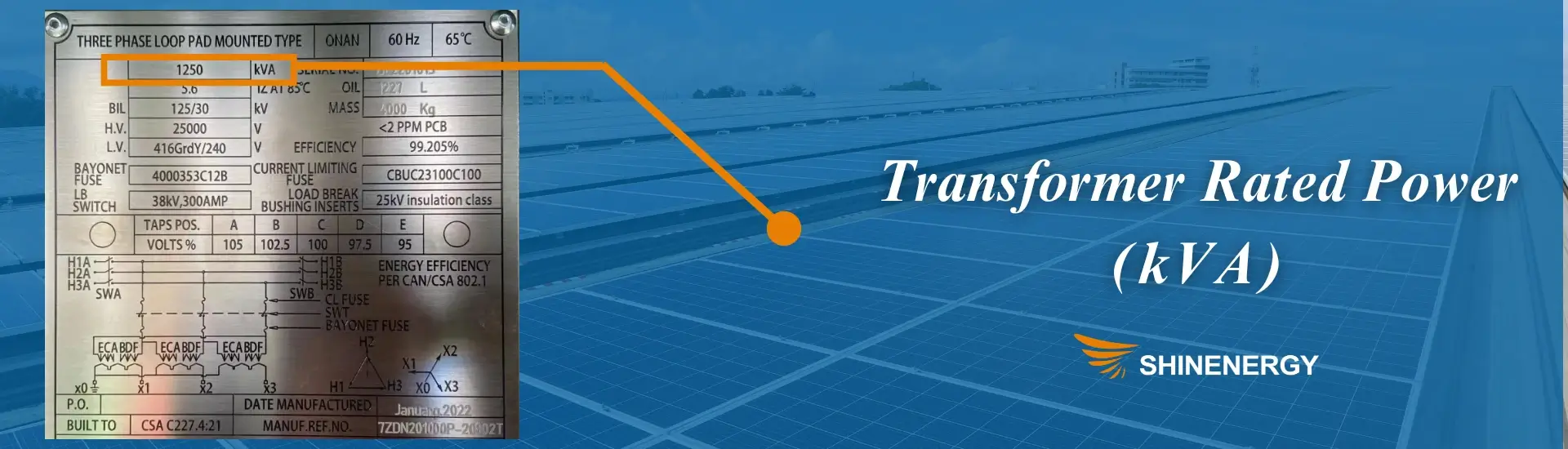

Transformer Rated Power (kVA)

Figure 2-1 transformer electricity symbol

How is transformer rated? This value shows the maximum load a transformer can handle. Choosing the correct kVA prevents overloading and inefficiency. The term capacity on a transformer nameplate refers to the maximum load it can handle, measured in kVA.Typical transformer sizes range from small 10 kVA units for residential use to large 1000 kVA transformers for industrial applications.

Voltage Ratings (HV/LV)

- Primary Voltage (HV):Input voltage from the power source.

- Secondary Voltage (LV):Output voltage for connected equipment.

Matching these values ensures system compatibility.

Frequency (Hz)

Figure 2-2 pictures of electrical transformers

Most transformers operate at 50 Hz or 60 Hz. Using the wrong frequency affects efficiency and performance. A transformer dimensions chart provides size specifications for different transformer types and ratings.

Impedance (%)

Impedance controls short-circuit current levels. Proper selection improves system protection and coordination. First Energy transformer pad specs define the required dimensions, load capacity, and installation guidelines for pad-mounted transformers.

Temperature Rise (°C)

This value indicates how much the windings heat up under load. Common ratings include 55°C, 65°C, and 75°C. Lower values improve lifespan.

Cooling Method (ONAN, ONAF, etc.)

- ONAN (Oil Natural Air Natural):Uses oil for insulation and air for cooling.

- ONAF (Oil Natural Air Forced):Adds fans for better heat dissipation.

Cooling methods affect transformer efficiency and durability.

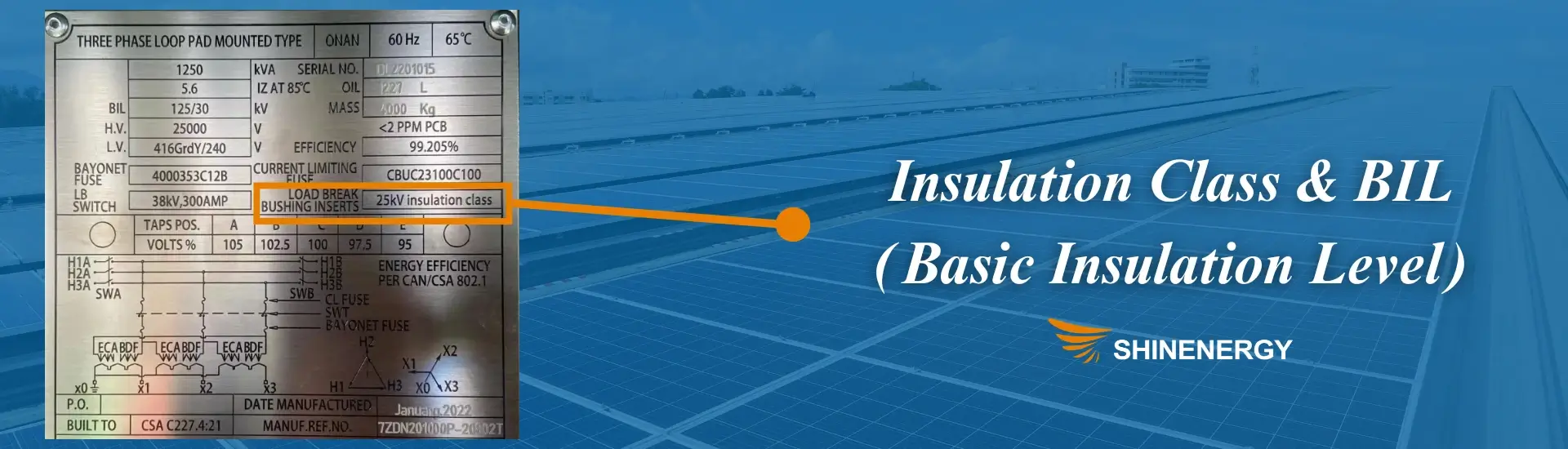

Insulation Class & BIL (Basic Insulation Level)

Figure 2-3 diagram transformer

BIL shows the maximum voltage a transformer can withstand. Higher ratings improve protection against surges and lightning.

Winding Material (Copper vs. Aluminum)

Figure 2-4 schematic for transformer

- Copper:Higher efficiency and better conductivity.

- Aluminum:Lower cost and lighter transformer

Nameplates specify the winding material for proper selection.

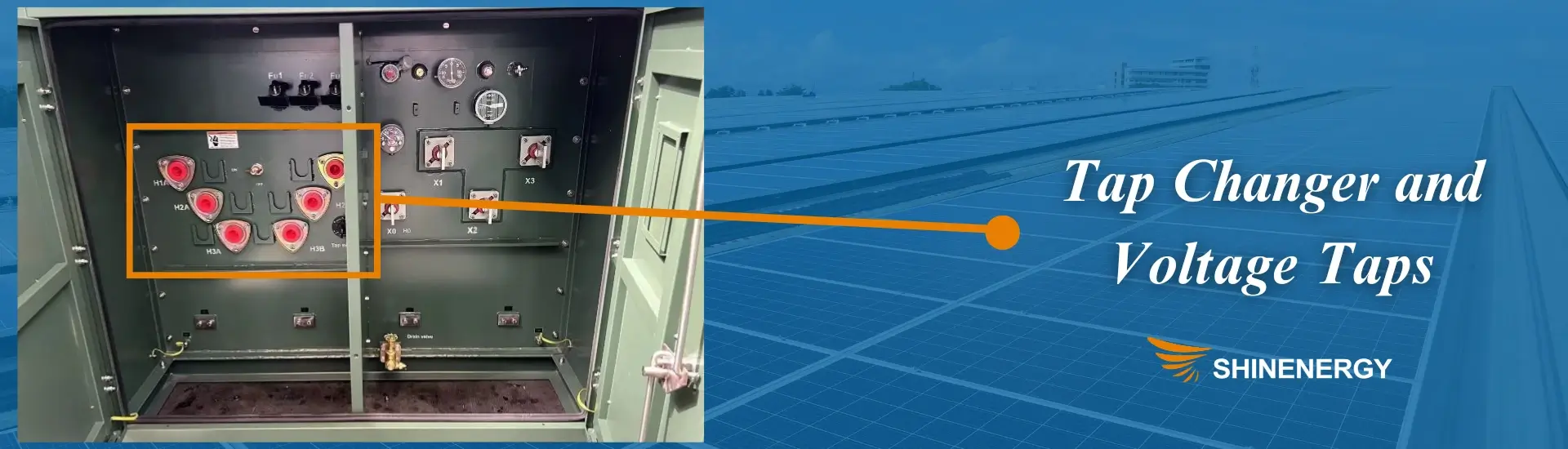

Tap Changer and Voltage Taps

Figure 2-5 electrical transformer photo

Voltage taps allow small adjustments to primary voltage. Engineers use them to maintain stable output. The transformer type determines its application, voltage rating, and insulation requirements.

Manufacturer Information & Serial Number

This data helps track production details, warranties, and replacements.

How to Use Transformer Nameplate Data

A nameplate of a transformer provides essential information for selecting, installing, and maintaining a transformer. Understanding this data ensures compatibility, efficiency, and safety.

Choosing the Right Transformer

Figure 3-1 electrical symbol of transformer

The nameplate of a transformer helps engineers select a transformer that meets system requirements. Checking the kVA rating ensures the transformer can handle the expected load. Matching primary (HV) and secondary (LV) voltages prevents compatibility issues. Selecting the correct frequency (50 Hz or 60 Hz) ensures efficient operation. Impedance values help manage short-circuit current, preventing system damage.

Installing the Transformer

Figure 3-2 electrical symbol for a transformer

Proper installation depends on the nameplate transformer specifications. Wiring configurations must align with system requirements to avoid misconnection. Voltage taps allow minor adjustments to compensate for supply fluctuations. Checking the cooling method (ONAN, ONAF, etc.) ensures the transformer receives adequate ventilation, preventing overheating and failure.

Performing Maintenance and Troubleshooting

Figure 3-3 transformer symbol schematic

Regular maintenance extends transformer lifespan and prevents failures. Temperature rise ratings indicate how much heat the transformer generates under load, helping technicians monitor performance. Cooling system details guide inspections of oil levels, fans, and radiators. Impedance and insulation ratings help diagnose electrical faults and ensure the system operates within safe limits. If issues arise, the manufacturer details and serial number provide essential information for repairs, replacements, and technical support.

Ensuring Compliance with Electrical Standards

Figure 3-4 nameplate transformer

Electrical standards ensure transformer safety and performance. The nameplate transformer lists compliance with IEC, ANSI, or IEEE standards, helping engineers confirm regulatory approval. BIL (Basic Insulation Level) ratings indicate the transformer’s ability to withstand voltage surges, reducing the risk of insulation failure. Checking these transformer specifications ensures transformers meet legal and operational requirements in different regions.

Shinenergy’s Transformer Nameplate Case Study

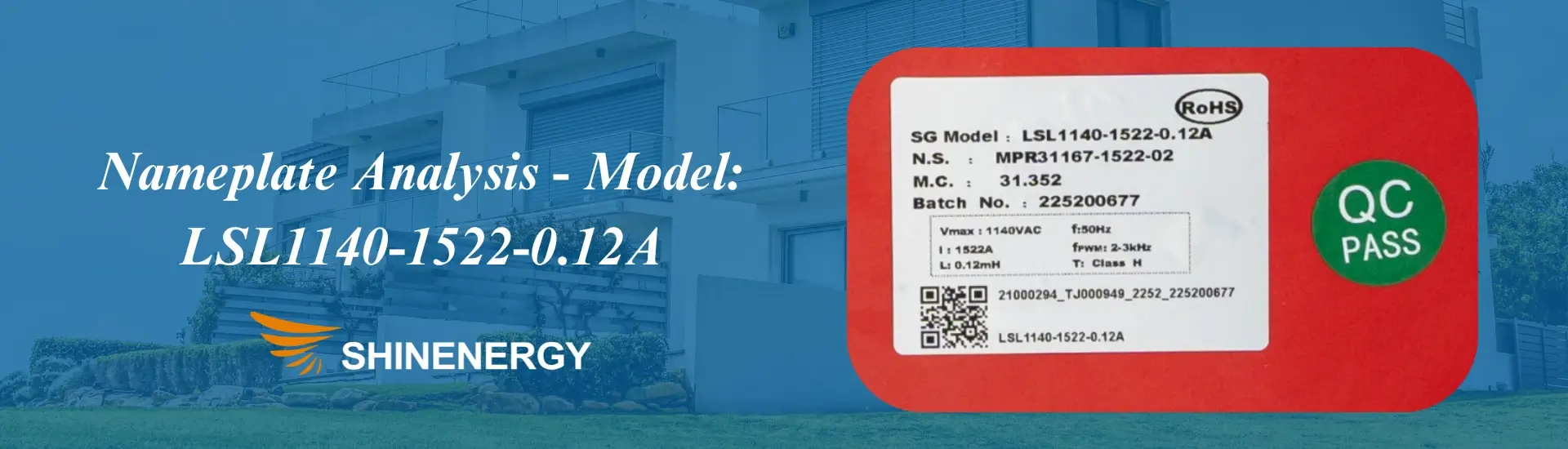

Nameplate Analysis – Model: LSL1140-1522-0.12A

Figure 4-1 3 phase transformer wiring schematic

Key Parameters:

- Model:LSL1140-1522-0.12A

- Serial Number (N.S.):MPR31167-1522-02

- Magnetic Core (M.C.):352

- Batch Number:225200677

- Maximum Voltage (Vmax):1140V AC

- Frequency (f):50Hz

- Current (I):1522A

- Inductance (L):12mH

- Pulse Width Modulation Frequency (fpwm):2-3kHz

- Insulation Class (T):Class H

Interpretation:

This transformer operates at 1140V AC with a frequency of 50Hz. It has a high current capacity of 1522A and an inductance of 0.12mH, which suggests it is designed for high-power applications. The pulse width modulation (PWM) frequency of 2-3kHz indicates possible use in power electronics or inverter applications. Class H insulation allows for higher operating temperatures.

Nameplate Analysis – Model: SHINENERGY-180-2

Figure 4-2 transformer label

Key Parameters:

- Part Number:282033928N00

- Model:SHINENERGY-180-2

- Type:DPM NA 275KVA

- Inductance (INV):04µH

- Current:330A

- Issue Number:E345752

- Manufacturer:SHINENERGY TECHNOLOGY (SHANGHAI) LTD

- Date:2022-11-25

Interpretation:

This transformer has a power rating of 275 kVA, suitable for medium to high-power applications. The 149.04µH inductance and 330A current capacity suggest a well-designed coil for high-load conditions. Manufactured by Shinenergy Technology (Shanghai) Ltd, the production date is November 25, 2022, indicating a relatively new unit.

Nameplate Analysis – Model: MPT32004-80-01

Figure 4-3 electric transformer picture

Key Parameters:

- Model:MPT32004-80-01

- Magnetic Core (M.C.):352

- Primary Voltage (Uprim):690/630/550V AC

- Secondary Voltage (Usec):400V AC

- Connection Group:Dyn11

- Insulation Class:H

- Date Code (D/C):224806984

- Power Rating (P):80 kVA

- Frequency (f):50Hz

- TransformerWeight: 360 kg

Interpretation:

This transformer has a primary voltage range of 690V, 630V, or 550V AC and a secondary output of 400V AC, making it ideal for step-down applications. The Dyn11 connection group is a standard vector grouping for three-phase transformers, ensuring proper phase shift. With a power rating of 80 kVA and a frequency of 50Hz, it is designed for medium-power applications. The transformer weight of 360 kg suggests a robust design.

Nameplate Analysis – Model: MPR10256-600-03

Key Parameters:

- Part Number (PN):MPR10256-600-03

- Inductance:5mH

- Current (Ir):600A

- Insulation Class:H

- Date Code (D/C):245201287

- Manufacturer Website:shinenergy.net

Interpretation:

This transformer has a high inductance of 5mH, making it suitable for applications requiring strong magnetic fields or energy storage. The 600A current rating indicates it is designed for heavy-load applications. Class H insulation provides resistance to high temperatures. The website www.shinenergy.net suggests that more details about the transformer can be found online.

Common Mistakes When Reading a Transformer Nameplate

Confusing Primary and Secondary Voltage

Many assume the higher voltage is always the primary. Always check HV (high voltage) and LV (low voltage) labels.Standard transformer sizes vary based on application, ranging from small 10 kVA units to large 1000 kVA or higher power ratings.

Ignoring Frequency (Hz)

Using a 50Hz transformer in a 60Hz system or vice versa affects performance. Always match the frequency with the power supply.Transformers sign is used to indicate high-voltage areas and safety precautions.

Overlooking Impedance (%)

Low impedance increases short-circuit current. High impedance affects voltage regulation. Choose the right value for system stability.A transformer selection chart helps engineers choose the right transformer based on voltage and load requirements.

Misinterpreting kVA Rating

kVA shows maximum load capacity. Running above this limit causes overheating. Always match kVA to system requirements.Meaning: Transformer is an electrical device that transfers energy between circuits by electromagnetic induction.

Neglecting Cooling Method

ONAN, ONAF, and KNAN indicate different cooling systems. Using the wrong method leads to overheating or reduced lifespan.The standard size of a transformer depends on its power rating and application.A wiring diagram of a transformer illustrates the connections between primary and secondary windings.

Forgetting Insulation Class

Class A, B, F, H define maximum operating temperatures. Ignoring this may cause insulation failure and transformer damage.

Skipping Nameplate Details in Maintenance

Maintenance teams often overlook tap settings, serial transformer numbers, and manufacturing details. These values help in troubleshooting and repairs.

Conclusion

Transformer nameplates provide essential data for selection, installation, and maintenance. Each unit serves different applications based on power rating, voltage, current, and insulation class. Understanding these details helps prevent mismatched installations, improves efficiency, and ensures safe operation. Proper interpretation leads to better performance, reliability, and longevity.

FQA

how to wire a step down transformer?

To wire a step-down transformer, first, turn off the power to ensure safety. Identify transformers the primary (high voltage input) terminals and connect the live (L) and neutral (N) wires from the power source to the corresponding terminals. Then, locate the secondary (low voltage output) terminals and connect them to the load based on the required voltage. If grounding is needed, attach the ground wire to the designated terminal. Double-check all connections, restore power, and test the output voltage to confirm proper operation. Always follow manufacturer guidelines and safety precautions.

what does a transformer look like?

A transformer electricity symbol represents different transformer types in circuit diagrams. The abbreviation for transformer varies, with “T” and “XFR” being commonly used. Common transformer sizes depend on application, ranging from small distribution units to large industrial transformers. Engineers refer to transformers symbols and names in schematics to ensure proper connections. A low voltage transformer wiring diagram helps in correctly connecting primary and secondary windings. The abbreviation of transformer simplifies labeling in electrical blueprints. Transformer VA rating indicates its apparent power capacity, crucial for load calculations. Some manufacturers use unique identifiers like an orange transformer name to categorize specific models.

How to Check Transformer Primary and Secondary?

To check the primary and secondary windings of a transformer, first, look at the nameplate to identify the primary (HV) and secondary (LV) terminals, usually labeled H1, H2 for primary and X1, X2 for secondary. Use a multimeter to measure resistance; the primary winding has higher resistance than the secondary. Applying a low AC voltage to the primary and measuring the secondary output can confirm step-up or step-down functionality. Always ensure the transformer is de-energized before testing.

How to Read Nominal Voltage?

Nominal voltage refers to the rated operating voltage of a transformer under normal conditions. It is listed on the transformer nameplate and includes both primary (HV) and secondary (LV) voltage levels. Standard nominal voltages include 480V, 230V, 120V, and 24V, depending on the application. While the actual voltage may vary slightly due to load conditions, it should remain within tolerance limits to ensure efficient performance.

How Much Does a Transformer Weigh?

A transformer’s weight depends on size, power rating, and construction materials. Small transformers (1-10 kVA) typically weigh 10-100 kg (22-220 lbs), while medium transformers (10-500 kVA) range from 100-2,000 kg (220-4,400 lbs). Large industrial transformers (500+ kVA) can weigh several thousand kilograms, and grid-scale transformers can exceed 100 metric tons. The actual weight can be found on the nameplate or manufacturer’s specifications.

How Much Do Transformers Weigh?

Transformers vary in weight depending on core materials, cooling method, and design. Dry-type transformers are generally lighter than oil-filled transformers due to the absence of insulating oil. Copper-wound transformers weigh more than aluminum-wound versions. As the kVA rating increases, the transformer becomes heavier due to more windings and insulation. Checking the nameplate or manufacturer specifications provides the most accurate weight for a specific transformer model.

Pingback: นำเข้ามอเตอร์ โบลเวอร์

Pingback: Source

Pingback: altogel