An autotransformer is a special type of transformer in which the input and output share the same winding. Compared with traditional isolation transformers, autotransformers have smaller size, higher efficiency, and lower cost, so they are widely used in many industrial and commercial applications. It varies the output voltage by adjusting the taps on the windings and is suitable for power systems that do not require strict electrical isolation. Although the autotransformers offers significant advantages in terms of space and material savings, it also poses certain safety risks in some applications.

What Is an Autotransformer?

Figure 1-1 autotransformer meaning

Autotransformer Definition

Figure 1-2 autotransformer law

An autotransformer is actually a special transformer. Its main feature is that the input and output share the same set of coils. It can change the output voltage by adjusting the tapping point of the coil, thereby achieving voltage up and down conversion. Imagine that just like the power socket in your home can adjust the voltage, the autotransformer can adjust the voltage in the circuit to make the equipment operate normally.

Characteristics of Autotransformer

Figure 1-3 autotransformer purpose

This type of transformers is special because it is small in size, high in efficiency, and lower in cost than traditional transformers. It is very suitable for use in situations where strict voltage isolation is not required. However, since the voltage output is not completely isolated from the input electrically, an autotransformer is one of the methods used to be used with caution in applications with high safety requirements.

How Does an Autotransformer Work?

Figure 2-1 function of autotransformer

What Is The Principle of Autotransformer?

Figure 2-2 autotransformers operation

the figure shows the autotransformers adjusts the voltage through a single winding. Its winding acts as both the primary and secondary sides. By setting different tapping points on the winding, different voltage conversions can be achieved. The current enters from the primary side and is distributed to the secondary side through specific tapping points, thereby increasing or decreasing the voltage. The simplicity of this structure gives the autotransformers advantages in size, cost, and efficiency, but it also limits its isolation performance and safety. This is like adjusting the volume knob to make the music louder or softer. Therefore, the autotransformers help us adjust the voltage in this way. Therefore, it is mainly used in occasions where voltage isolation requirements are not high.

Difference of Autotransformer vs Transformer

Figure 2-3 transformer vs autotransformer

Differences in structure and function

Figure 2-4 autotransformer reduced voltage starter

Autotransformers use one winding to adjust the output voltage through different tapping points; conventional transformers have two independent windings that convert voltage through electromagnetic induction and provide better electrical isolation.

Differences in cost and volume

Figure 2-5 autotransformer schematic

Due to their simple structure, autotransformers have less production costs and materials required, making them more economical and smaller than conventional transformers.

Differences in efficiency

Figure 2-6 autotransformer split phase

Autotransformers have a simpler design, making them more energy-efficient in some applications; conventional transformers may have slightly lower efficiency due to their complex design.

Differences in safety and isolation

Figure 2-7 autotransformer starter diagram

Conventional transformers provide complete electrical isolation and are suitable for environments with high safety requirements; due to structural limitations, autotransformers are not as safe and isolated as conventional transformers.

Differences in applicable scenarios

Figure 2-8 autotransformer starter

Autotransformers are usually used in situations where isolation requirements are not high, such as some power adjustment applications; conventional transformers are suitable for environments that require strict voltage control and high safety standards, such as medical and high-precision equipment.

What Are Autotransformers Used For?

Figure 3-1 autotransformer theory

Application of Autotransformer

Power Industry

Figure 3-2 autotransform

Autotransformers are critical in this industry because they can effectively adjust voltage and help achieve efficient power transmission. This is especially important in large-scale power grids, such as when the voltage is reduced or increased, they can maintain a stable supply of power.

Heavy Industry

Figure 3-3 autotransform

In manufacturing, especially heavy industry, many large machines and production line equipment require precise voltage regulation to ensure production efficiency and safety. The role of autotransformers here is to ensure that this equipment can operate at the most suitable voltage.

Railway Transportation

Figure 3-4 audio autotransformer

In modern electrified railway systems, autotransformers are used to regulate the supply of electricity from the grid to the rails. They help the railway system maintain a constant voltage, ensuring the smooth operation of trains and the accuracy of railway signal systems.

Communication Infrastructure

Figure 3-5 autotransformer advantages

Many devices in the communication industry, such as transmission towers and data centers, require stable and reliable power. Autotransformers are used in these applications to prevent voltage fluctuations, thereby ensuring the continuity of communication and the security of data.

Buildings and Commercial Facilities

Figure 3-6 autotransformer ballast

In large commercial buildings or complex building complexes, autotransformers are used to manage and adjust the power needs of different floors and areas. This adjustment ensures efficient use of electricity and increases the flexibility of energy management.

Advantages and Disadvantages of Autotransformer

Figure 4 autotransformer advantages and disadvantages

What Is a Advantage of an Autotransformer?

Figure 4-1 advantages of autotransformer

The advantages of autotransformers are their cost-effectiveness, small size, and high efficiency. Their simple design uses less material, which reduces manufacturing costs. At the same time, the single winding structure makes it smaller, which is very suitable for space-constrained environments. In addition, due to its simple construction, autotransformers usually achieve high efficiency in applications where voltage regulation is not large, especially when transmitting relatively low voltage changes.

What Is a Disadvantage of an Autotransformer?

Figure 4-2 autotransformer calculations

Disadvantages of autotransformers include a lack of electrical isolation and limited voltage regulation capabilities. Since they only have a single winding in their design, they do not provide complete electrical isolation like conventional transformers, which can cause safety issues, especially in applications where sensitive equipment needs to be protected. In addition, autotransformers do not have the same range and flexibility in voltage regulation as conventional transformers, limiting their use in complex applications that require precise voltage control. Under high load conditions, autotransformers may also generate more heat, requiring additional cooling measures.

What Cases Is It Suitable to Use an Autotransformer?

Figure 4-3 autotransformer calculator

Autotransformers are suitable for use in applications where the voltage adjustment range is small and electrical isolation is not required. For example, in large power transmission systems, it can effectively reduce costs and improve efficiency. In factories or industrial equipment, autotransformers are often used to adjust the voltage to ensure stable operation of equipment. In addition, their small size and high efficiency make them very suitable for space-saving applications in environments with limited space and low safety requirements. However, it should be noted that autotransformers are not very suitable for applications where strict electrical isolation is required.

Conclusion

Figure 5-1 isolation transformer vs autotransformer

Autotransformers are favored for their simple structure and cost-effectiveness, making them ideal where strict electrical isolation isn’t needed. However, because they don’t fully isolate, proper safety measures are crucial, especially with sensitive equipment. If your application tolerates lower isolation and prioritizes efficiency and cost, autotransformers are a great option.

FAQ1

What Is The Voltage Supplied to The Autotransformer Called?

Figure 6-1 autotransformer circuit

The voltage supplied to autotransformers is typically called the “input voltage” or “primary voltage.” This is the voltage that is initially applied to the primary winding of the autotransformers from the external power source. Ensure the proper autotransformers grounding to enhance safety and prevent electrical faults by connecting the transformer’s neutral or ground point to the system ground, following electrical codes.

What Does The Autotransformer Control?

Figure 6-2 autotransformer connection

The autotransformers control the output voltage supplied to the load. It adjusts the voltage either by stepping it up or stepping it down from the primary voltage, based on the needs of the connected equipment. This adjustment is made through a single winding with multiple taps at different points, allowing for different voltage levels to be selected.

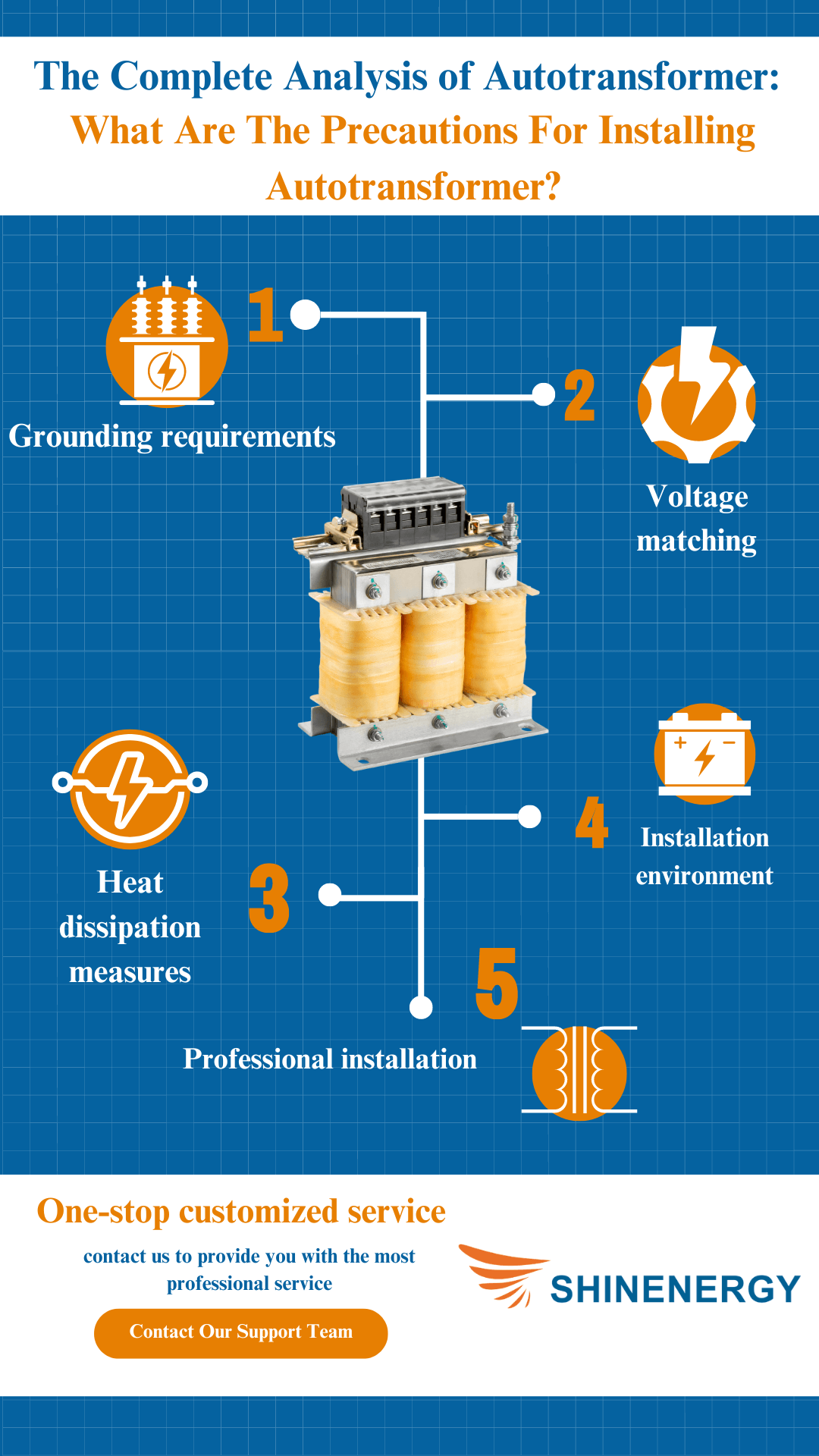

What Are The Precautions For Installing Autotransformer?

Figure 6-3 Autotransformer construction

Grounding requirements

Ensure that the load-side terminals of the autotransformers are properly connected to the grounding conductor of the power supply system. This step is critical because the autotransformers do not provide complete electrical isolation.

Voltage matching

Before installation, verify that the voltage level of the autotransformers matches the system requirements to avoid equipment damage caused by voltage mismatch.

Heat dissipation measures

Since the autotransformers may generate heat during operation, ensure that there is appropriate heat dissipation space or heat dissipation facilities.

Installation environment

Select an appropriate installation location and avoid environments with humidity, excessive dust, or corrosive substances to extend the service life of the transformer.

Professional installation

Given the electrical characteristics of autotransformers, a qualified electrician should install and maintain them to ensure compliance with local electrical safety regulations during all operations.

What Is a Variable Autotransformer?

Figure 6-4 autotransformer design

Variable autotransformers are a type of transformer that allows for continuous adjustment of the output voltage without complete electrical isolation between the primary and secondary windings. Commonly used in laboratories and industrial settings, it offers precise voltage control and is ideal for applications that require variable voltages.

What Are The Symbols of Autotransformer?

Figure 6-5 Autotransformers disadvantages

What Are The Types of Autotransformers?

Figure 6-6 types of autotransformer/autotransformer starting

- step down autotransformer

- step down autotransformer diagram

- step up autotransformer

- step up autotransformer diagram

- 120 240 autotransformer

- 120/240 autotransformer

- 18 pulse autotransformer

- 18-pulse autotransformer

- 3-phase autotransformer

- 49 1 autotransformer

¿Qué es un “diagrama unifilar arranque autotransformador”?

Figure 6-7 autotransformers vs isolation transformer

Un “diagrama unifilar arranque autotransformador” se refiere a un diagrama unifilar utilizado para ilustrar el circuito de arranque de un autotransformador. Este tipo de diagrama es crucial para entender cómo se configura un autotransformador para ajustar los niveles de voltaje durante el arranque en diversas aplicaciones industriales, proporcionando una representación clara y simplificada de las conexiones eléctricas y los componentes involucrados.

¿Qué representa un “diagrama unifilar arranque por autotransformador”?

Figure 6-8 autotransformers vs two winding transformer

Un “diagrama unifilar arranque por autotransformador” muestra la configuración eléctrica para el arranque de maquinaria o sistemas utilizando un autotransformador. Este tipo de diagrama ayuda a visualizar cómo se distribuye la energía eléctrica y cómo se ajusta el voltaje inicial para el arranque eficiente y seguro de los equipos.

What is the difference between an isolation transformer and an autotransformer?

The key difference between an isolation transformer and autotransformers lies in the design of their windings. An isolation transformer has separate primary and secondary windings, which provide full electrical isolation between the input and output. In contrast, autotransformers use a single, shared winding for both input and output, offering no electrical isolation but with advantages in terms of size, efficiency, and cost. The choice depends on the need for isolation versus efficiency and cost savings.

Pingback: oak pellets bulk

Pingback: โครงการแลกเปลี่ยน

Pingback: รับทำแพคเกจจิ้ง

Pingback: เว็บสล็อต

Pingback: skachatpinapprilozhenie.website

Pingback: Translation Services in Koh Samui

Pingback: essentials fear of god

Pingback: รับจด อย

Pingback: Thermage