Powder Core DC Boost Inductor

Shinenergy’s powder core DC boost inductor is one of the DC boost inductors made up of powder core and copper winding, which could store the energy and boost the voltage, widely applied in the electric circuit to reduce the harmonic.

- Potted structure

- High-quality core and winding material

- Outstanding R&D design to reduce the temperature rise

- CE, UL certificated

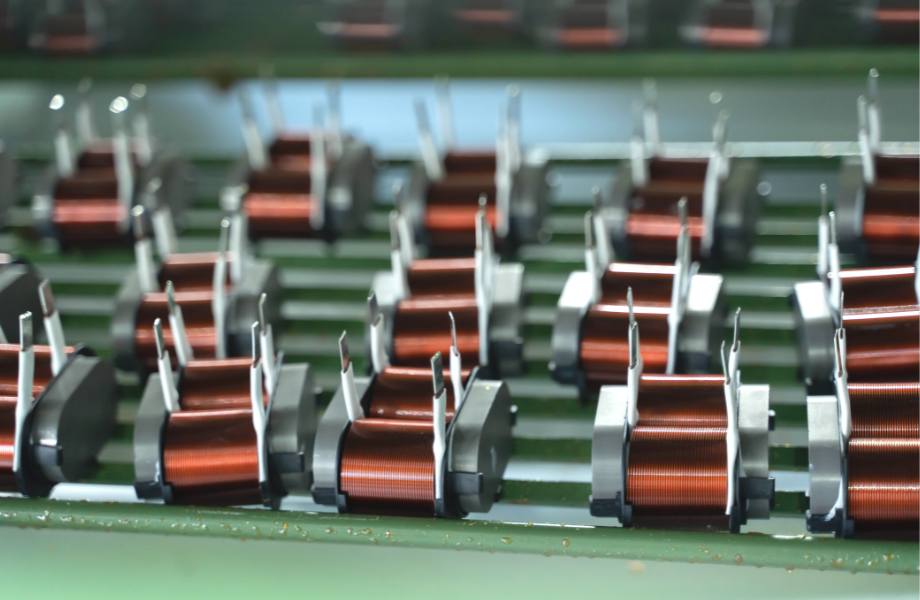

Copper Winding Material

Adopt the copper vertical winding, the conductivity of aluminum wire and copper wire is different, and the physical properties of aluminum determine that aluminum wire cannot be drawn as thin as copper wire, so the cross-section of aluminum wire should be twice as large as that of the copper wire. The resistance value of the aluminum wire with the same cross-sectional area is higher than that of the copper wire, so to obtain the same current, y must increase the cross-sectional area of the aluminum wire

Could be Produced in Batches

Small size and copper vertical winding make Shinenergy’s powder core DC boost inductor could be produced in batches, increase the production efficiency and reduce the cost relatively.

- Data sheet

- FAQs

| Model No. | MPR-006 |

| Application | PV Inverters |

| Core Material | Powder core |

| Winding Material | Copper wire vertical winding |

| Structure | Potted |

| Rated Inductance | 1.32mH |

| Rated Current | 30A |

| Weight | 2.5KG |

Q1: Where could be this powder core DC boost inductor applied?

A1: Shinenergy’s powder core DC boost inductor could be applied for PV inverters.

Q2: What’s the function of the powder core DC boost inductor?

A2: Powder core DC boost inductor used to step up the supply voltage and output the higher voltage.

What are the advantages of powder core DC boost inductors?

Shinenergy’s powder core DC boost inductor with all advantages of the typical DC boost inductor, due to choosing the powder core, the power loss of the whole inductor is less, and it’s moisture-proof because of the potted structure. The efficiency of the inductor is higher with the copper winding compared with the aluminum winding.