Sine Wave Inductor is an indispensable component in modern electronics, playing a critical role in ensuring the efficiency and reliability of AC circuits across diverse industries. With ongoing advancements in materials, design, and manufacturing techniques, manufacturers like Shinenergy are at the forefront of delivering customized solutions that meet the specific needs of their customers. Whether for telecommunications, automotive, aerospace, or renewable energy applications, Shinenergy’s commitment to innovation and quality ensures that its Sine Wave Inductor exceed expectations and drive technological progress forward.

What is a Sine Wave Inductor?

Fundamental Role in AC Circuitry

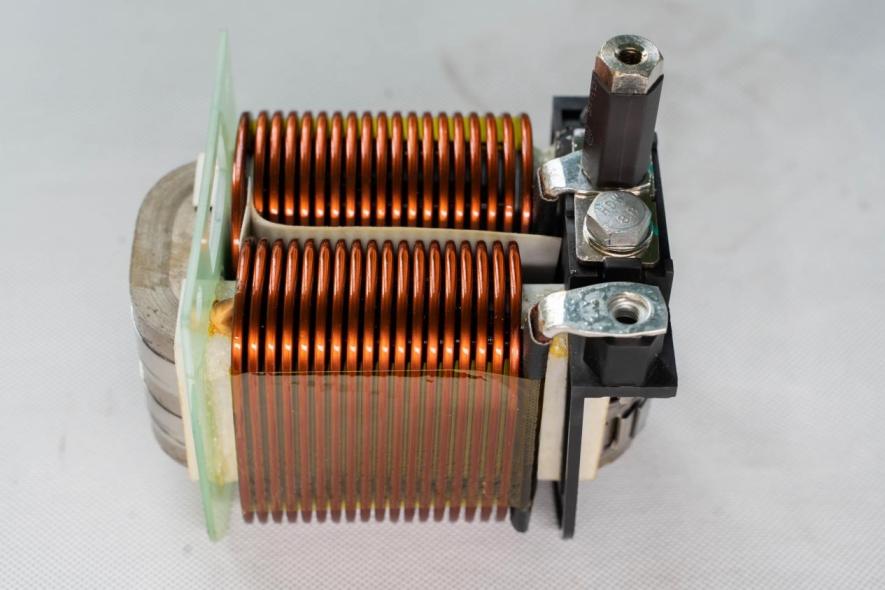

Sine Wave Inductor is a crucial component in electrical circuits, particularly in alternating current (AC) applications. They primarily function to store energy in the form of a magnetic field when current flows through them. This stored energy opposes changes in current, thereby stabilizing and smoothing the flow of AC signals. In essence, Sine Wave Inductor play a pivotal role in ensuring the efficiency, reliability, and performance of electronic systems across various industries.

Key Characteristics and Applications

These inductors exhibit specific characteristics such as inductance, which determines their ability to store energy, and reactance, which influences their impedance in AC circuits. Industries leverage Sine Wave Inductor in telecommunications for signal processing, automotive for power management in electric vehicles, aerospace for avionics, and renewable energy for inverters and converters. Their applications range from power conditioning and filtering to frequency tuning and voltage regulation.

Importance in Modern Electronics

As electronic devices become more sophisticated and compact, the demand for efficient energy management and signal integrity grows. Sine Wave Inductor, with their ability to handle high currents and maintain stability over a wide frequency range, are indispensable in meeting these evolving technological requirements.

Latest Technology in Sine Wave Inductor

Innovations in Materials and Design

Recent advancements in materials science have significantly enhanced the performance and capabilities of the Sine Wave Inductor. Manufacturers like Shinenergy utilize materials such as ferrite, powdered iron, and specialized alloys that offer superior magnetic properties and thermal stability. These materials enable inductors to achieve higher efficiency, lower losses, and better reliability in demanding operating conditions.

Advanced Manufacturing Techniques

Technological innovation extends to manufacturing processes, where precise winding techniques and automated assembly ensure consistency and quality in production. Modern facilities equipped with state-of-the-art machinery allow for the customization of inductors to meet specific customer requirements regarding size, shape, and performance characteristics.

Integration of Smart Technologies

The integration of smart technologies and digital enhancements in Sine Wave Inductor is another area of rapid development. These technologies include embedded sensors for real-time monitoring of temperature and current, which enhances operational reliability and enables predictive maintenance strategies in industrial applications.

Market Status of Sine Wave Inductor

Essential Components for Precision AC Control

Sine Wave Inductor is an indispensable component in industries that require precise control over alternating currents (AC). They are extensively utilized across diverse sectors including telecommunications, power electronics, automotive, aerospace, and renewable energy. The market for Sine Wave Inductor is experiencing steady growth, driven by technological advancements and the increasing complexity of electronic systems.

Applications Across Key Industries

Industries rely on Sine Wave Inductor for their ability to regulate and stabilize AC currents, making them crucial in applications where efficiency and reliability are paramount. These industries include telecommunications for signal processing, automotive for power management in electric vehicles, aerospace for avionics, and renewable energy for inverters and power converters.

Growth Drivers

The market expansion is fueled by innovations that enhance the performance and versatility of the Sine Wave Inductor. As industries evolve towards more sophisticated electronic solutions, the demand for high-performance inductors capable of meeting stringent operational requirements continues to rise.

Current Industry Needs

High Efficiency Demands

In today’s competitive landscape, industries demand Sine Wave Inductor that minimizes energy losses and maintains high efficiency, especially in power conversion applications. This requirement ensures optimal energy usage and cost-effectiveness in operational environments.

Reliability in Challenging Environments

For critical applications in the automotive sectors, reliability is non-negotiable. Sine Wave Inductor must withstand extreme conditions such as high temperatures, vibrations, and electromagnetic interference while delivering consistent performance over extended operational lifetimes.

Miniaturization for Compact Designs

The trend towards miniaturization in electronics necessitates Sine Wave Inductor that is not only powerful but also compact. These components must fit into increasingly smaller spaces within electronic devices without sacrificing performance or efficiency.

Customization for Varied Applications

Industries often require customized solutions to meet specific application needs. This customization could involve variations in voltage ratings, current handling capacities, physical dimensions, or environmental resilience. Tailored Sine Wave Inductor enables seamless integration into diverse systems and applications.

Solutions Offered by Sine Wave Inductor

Innovations in Materials and Design

Manufacturers like Shinenergy leverage advancements in materials science and design techniques to enhance the efficiency and reliability of Sine Wave Inductor. Materials such as ferrite, powdered iron, and specialized alloys are chosen to optimize performance parameters such as inductance, saturation current, and thermal stability.

Ensuring Temperature Stability

Sine Wave Inductor are designed to operate reliably across a wide range of temperatures. Advanced thermal management techniques and materials ensure stability under extreme environmental conditions, maintaining consistent performance over varying operational scenarios.

Achieving High Power Density

Modern Sine Wave Inductor achieves high power density through innovations in magnetic core materials and winding techniques. These advancements enable compact designs that deliver robust performance, meeting the demands of space-constrained electronic applications without compromising on efficiency or reliability.

Flexible Customization Options

Shinenergy offers a range of customization options tailored to specific industry requirements. This includes variations in inductance values, current ratings, and physical form factors to ensure seamless integration into diverse applications. Customized solutions empower industries to optimize performance and achieve operational goals effectively.

Shinenergy: Leading the Way in Sine Wave Inductor Manufacturing

Commitment to Quality and Innovation

Shinenergy stands at the forefront of sine wave inductor manufacturing, driven by a commitment to quality and continuous innovation. With a focus on advancing materials, refining design methodologies, and integrating cutting-edge technologies, Shinenergy consistently delivers products that exceed industry standards.

Research and Development Excellence

The company’s dedicated research and development teams are instrumental in pushing the boundaries of sine wave inductor technology. By investing in R&D, Shinenergy pioneers new materials and manufacturing processes that enhance product performance, reliability, and efficiency.

Industry Partnerships and Collaborations

Shinenergy fosters collaborative partnerships with industry leaders to anticipate market trends and develop solutions that address emerging challenges. These partnerships ensure that Shinenergy’s Sine Wave Inductor is not only technically superior but also aligned with the evolving needs of global industries.

Customer-Centric Approach

Tailored Solutions for Diverse Applications

Understanding that every industry has unique requirements, Shinenergy offers personalized consultancy and customization services. This customer-centric approach enables Shinenergy to develop bespoke sine wave inductor solutions that precisely match the specific needs of each application.

Comprehensive Support and Service

Beyond product innovation, Shinenergy prides itself on providing comprehensive support and service throughout the product lifecycle. From initial design consultations to post-sales technical support, Shinenergy remains dedicated to ensuring customer satisfaction and success.

Sustainable Manufacturing Practices

Shinenergy is committed to sustainable manufacturing practices, incorporating environmental considerations into every aspect of its operations. By prioritizing energy efficiency, waste reduction, and responsible sourcing, Shinenergy contributes to a cleaner and greener future for the industry and society at large.

Conclusion

Sine Wave Inductor plays a pivotal role in modern industries, enabling precise control over AC currents and supporting the advancement of electronic systems across diverse applications. As the market continues to expand, driven by the demand for efficiency, reliability, and customization, manufacturers like Shinenergy are at the forefront, delivering innovative solutions that meet and exceed industry expectations.

By leveraging advanced materials, rigorous design principles, and a customer-centric approach, Shinenergy remains a trusted partner for industries seeking high-performance Sine Wave Inductor. As technologies evolve and industries innovate, Shinenergy stands ready to collaborate and innovate, shaping the future of sine wave inductor technology for a connected and sustainable world.

Pingback: เกมสล็อตยอดนิยมจากค่าย FastSpin