Understanding Enclosed Transformers: A World of Power in a Protective Shell:

- Enclosed transformers have their internal components housed inside a sealed enclosure, as opposed to open-wound transformers, which have exposed coils. This enclosure has several benefits, such as:

- Weatherproof Design: Enclosed transformers are perfect for outdoor applications since they are made to endure inclement weather.

- Fire Resistance: An extra line of defense against fire threats is offered by the enclosure.

- Enhancement of Safety: By reducing the possibility of unintentional contact with active electrical components, the enclosure raises standards of general safety.

- Noise Reduction: When compared to open-wound transformers, enclosed transformers usually operate at lower noise levels.

- Lower Maintenance: The transformer is shielded from dust, dirt, and other impurities by the sealed enclosure, which reduces the need for maintenance.

Types of Enclosed Transformers: Tailored Solutions for Diverse Needs

Enclosed transformers are available in different configurations to suit different needs. Below is a summary of some typical types:

- Dry-type transformer:

The most popular kind of transformers, dry-type transformers employ inert gas or air as cooling agents. Their fire-resistant qualities make them useful for interior applications.

- Transformers Encapsulated in Epoxy Resin:

These transformers provide superior flame retardancy and environmental protection.

- Pad-Mounted Transformers:

Located on a concrete platform, pad-mounted transformers are encased in a weatherproof casing and are intended for subterranean installations. They are frequently utilized in networks for power distribution.

- Pole-Mounted Transformers:

Usually used for temporary power distribution purposes or in rural locations, these transformers are mounted on utility poles.

- Substation Transformers:

These high-capacity transformers, which are located in electrical substations, reduce voltage before sending it to distribution lines.

Material Considerations: Aluminum vs. Copper Windings

The performance and cost of the transformer are influenced by the conductor material used in the windings (coils):

- Copper Wound Transformers: Copper windings are the conventional option because they provide better conductivity and less energy losses. They are often more costly than aluminum substitutes, though.

- Transformers with Aluminum Wounds: An increasingly common alternative, aluminum windings are less expensive. Although their energy losses are somewhat larger than those of copper, technological developments have reduced this difference.

Applications Galore: Where Enclosed Transformers?

Enclosed transformers are essential in several industries:

- Industrial electricity Distribution:

These transformers are used in factories, manufacturing plants, and other industrial facilities to reduce the high-voltage electricity needed to run machinery and equipment.

- Commercial Buildings:

These transformers are used in office buildings, retail centers, and other commercial buildings to distribute energy for HVAC systems, lighting, and other uses.

- Building Sites:

On building sites, portable transformers supply equipment and tools with temporary electricity.

- Integration of Renewable Energy:

To incorporate renewable energy sources into the grid, such as solar and wind power, enclosed transformers are a necessary component.

- Machine Tool Control Systems:

These transformers supply the voltage levels required to power industrial robots’ and machines’ control systems.

Factors to Consider: When Choosing an Enclosed Transformer?

When choosing an enclosed transformer, it’s important to carefully evaluate the following factors:

- KVA Rating:

This represents the transformer’s ability to handle power. Select a KVA value that allows for some margin for any surges while satisfying the total power requirements of your equipment.

- Voltage:

Verify that the input and output voltages of the transformer meet the needs of your power source and application.

- Phase (Single- or Three-Phase):

Your power supply and application will determine how many phases you need. In residential settings, single-phase transformers are typical; in industrial settings, three-phase transformers are used to meet increased power needs.

- Rules and Safety:

Make sure the enclosed transformer always meets the necessary safety requirements, such as NEMA ratings and UL registration.

Safety First: Crucial Things to Know When Using Enclosed Transformers

- Enclosed transformers still handle high-voltage energy, but because of their sealed enclosures, they provide a notable safety benefit over open-wound transformers. Hazardous situations or even death might result from improper handling or disobedience of safety procedures. When working with these transformers, keep the following points in mind:

- Double-Check the Voltage: Before activation, make sure the transformer’s input and output voltage ratings correspond to the power supply and planned use. Voltage mismatches can cause equipment damage or provide safety risks.

Grounding Is Essential:

These transformers must be properly grounded to safely operate. By allowing any stray current to safely return to Earth, grounding reduces the possibility of an electrical shock. Make sure the grounding procedure is handled by a licensed electrician.

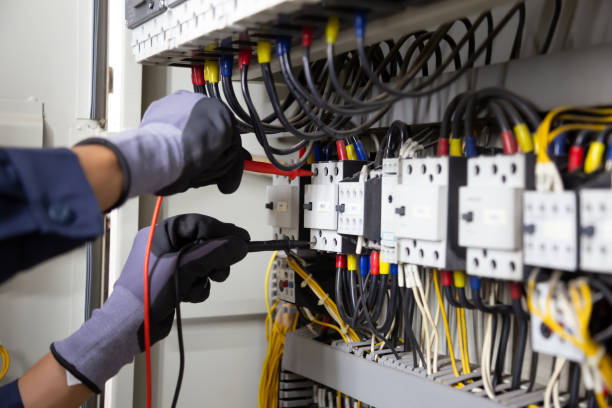

Equipment for personal protection (PPE):

Qualified electricians are required to wear proper Personal Protective Equipment (PPE) when working with or near high-voltage systems, especially enclosed transformers. This includes safety eyewear, insulated gloves suited for the relevant voltage levels, and flame-resistant apparel.

Best Enclosed Transformers for Construction Sites: Powering up Your Projects Safely:

A dependable and secure temporary power supply is necessary for a variety of tools and equipment used on construction sites. To power these machines, enclosed transformers are essential since they reduce high voltage energy (usually 480V) to a workable level (usually 120V). But with so many alternatives, there are a lot of considerations to consider when selecting the ” best” enclosed transformer for your building site . Here’s a guide to assist you in choosing the best one:

- Power Requirements (KVA Rating):

Determine the total power requirements of all the tools and equipment you want to employ on the site (KVA rating). Select a transformer with a KVA rating higher than your overall power need, taking into account possible peak loads. It is advised to have a buffer of 20–30% to provide for future expansion and surges.

- Voltage Compatibility:

Verify that the input voltage of the transformer is compatible with the power supply that is available on the building site (usually 480V). Most of your construction tools should work with the output voltage, which is typically 120V.

Conclusion:

You may choose the finest enclosed transformers for your building site by carefully weighing your demands in terms of power, mobility, and safety features. Never forget that safety comes first. When it comes to installation, maintenance, and any concerns about safe functioning, it is always advisable to consult certified electricians at our website, Shinenergy.

Pingback: เว็บพนันออนไลน์เกาหลี

Pingback: Angthong National Marine Park