Customize Your High Frequency Inductor

- Certifications:For clients who prioritize quality and compliance, Shinenergy’s inductors are certified to ISO9001, IATF16949, and environmental standards, ensuring each product meets global benchmarks for reliability and safety. Every inductor is manufactured under strict quality controls to give you confidence in performance and consistency, especially under demanding operational conditions.

- Performance and Craftsmanship:Addressing common challenges like power losses and overheating, Shinenergy’s inductors are crafted with high-quality magnetic materials and precise automated manufacturing processes, including advanced winding and controlled coating. This ensures low energy loss, optimal thermal stability, and robust performance, minimizing your risk of downtime and enhancing operational efficiency.

- Application Fields:Shinenergy inductors support critical applications across PV energy storage, EV charging, data centers, UPS systems, and more. Designed for high-frequency and high-load operations, our inductors provide reliable, stable power conversion to keep essential systems running smoothly, even under challenging conditions.

Why is Shinenergy's customized service always deeply appreciated?

Shinenergy’s customized service is deeply appreciated because we prioritize what matters most to you: precision, reliability, and seamless integration. We don’t just build inductors—we engineer solutions tailored to your unique challenges.

Leveraging advanced circuit analysis, magnetic simulation, and thermal modeling, our designs deliver unmatched power density and heat management. Each project starts with a thorough understanding of your specific needs, ensuring our inductors enhance your system’s efficiency and resilience. With Shinenergy, you gain a partner who values your success as much as you do.Contact us today to learn more!

Inductor application range covers multi-industry power needs

Residential Single-Phase Units/Residential Three-Phase Units/Commercial & Industrial Distributed Stations/Ground-Based Distributed Stations

Residential Single-Phase Storage Systems/Residential Three-Phase Storage System/Bidirectional DC-DC Systems/Ground Station Storage Systems

OBC-DC-DC Systems/OBC-PFC Systems/800V Onboard Boost Systems/Commercial Hydrogen Fuel Cell Electric Vehicles

Multiple core types to meet your diverse customization needs

Shinenergy’s wide range of core options are designed to meet your customized needs. Whether it’s power density, thermal optimization, or high-frequency performance, we ensure that our inductors are stable, low-loss, and efficiently support your application to help you achieve your goals.

INDUCTOR TYPES

Shinenergy's Eight Core Processes for Lean Manufacturing

Vertical winding of 50mm² flat wires, characterized by high efficiency, reliability and batch traceability.

Pin stripping and tinning in a single pass ensures a safe, efficient and reliable production process.

Uniform and controllable dispensing volume on the core bonding surface ensures efficient and reliable bonding quality.

Immersion baking is accomplished in a single pass, ensuring high efficiency, reliability, and traceability for each batch.

An environmentally friendly and efficient resistance welding process is utilized to ensure reliability and batch traceability.

Glue filling and baking in a single pass, with controlled glue volume to ensure batch traceability.

Real-time detection of data anomalies and alarms to ensure traceability of data for each product.

Automation of key positions, IT-based management, and professionalization of personnel to ensure the stability of key positions.

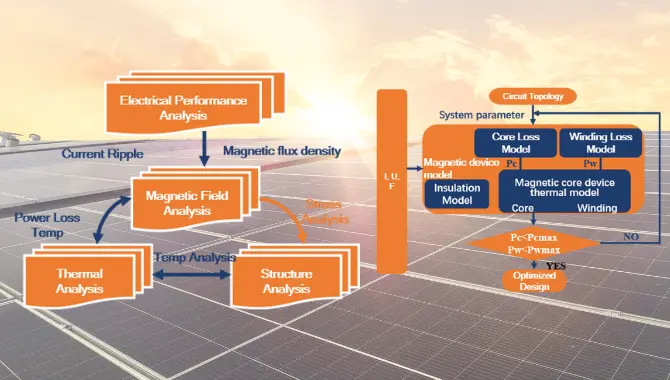

Advanced Design Capabilities for Customized Performance

At Shinenergy, our design capabilities span precise circuit analysis, magnetic and thermal simulations, and custom structural optimization to ensure your power solutions are efficient and reliable. From maximizing power density to meeting complex specifications, we provide tailored solutions that elevate your system’s performance. Trust Shinenergy for engineering excellence in every detail.

Shinenergy’s Precision in Circuit Analysis and Custom Design

Shinenergy has in-depth circuit analysis capabilities, and can accurately analyze the electromagnetic parameters under various working conditions and verify their reasonableness. We provide our customers with specialized advice and tailor-made solutions to ensure the best matching of product performance. With our strong customized design capabilities, we help our customers achieve more efficient and reliable power systems.

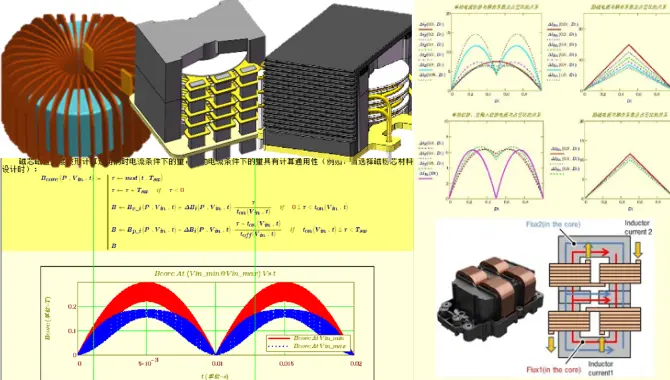

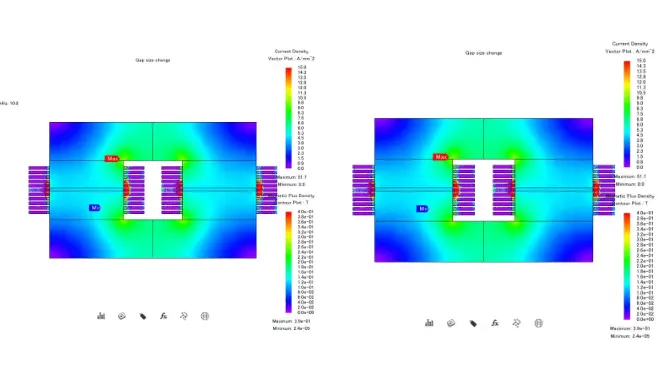

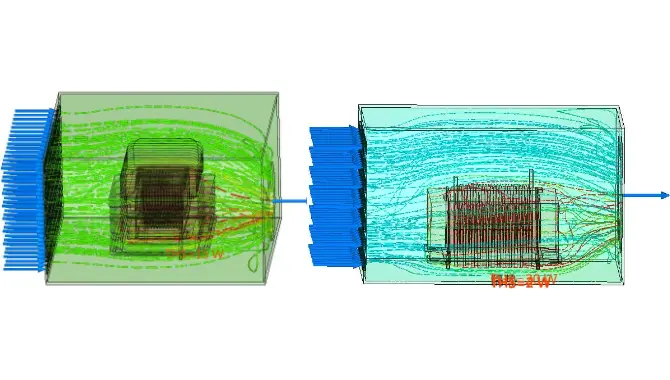

Magnetic simulation optimization for your tailor-made electrical solutions

Shinenergy has advanced magnetic simulation capabilities to prevent localized overheating by accurately analyzing flux density and temperature distribution for reliable designs. We optimize the core structure and air gap size according to customer requirements and provide customized solutions for each project. Our strong customized design capability allows us to build highly efficient and stable electromagnetic products for our customers to meet the needs of various complex application scenarios.

Accurate Thermal Simulation Technology for Customized electric Solutions

Shinenergy’s thermal simulation capability ensures that your systems perform reliably under high power demands. We meticulously verify heat dissipation across both structural and material levels, designing customized, high-power-density solutions to prevent overheating and maximize efficiency. With Shinenergy, you gain a partner focused on delivering precise, tailored solutions that meet your specific thermal management needs and ensure optimal performance across various applications.

Related Products

AC Inductor is specified for the AC electrical circuit, there are three-phase AC inductors and single-phase AC inductors. AC inductor and capacitor are connected in series to form a non-power compensation device.

Widely applied in the DC-DC electrical circuit, DC boost inductor is applied for step up the input voltage to a high voltage at output, the voltage increase ratio is up to the load within the circuit.

Shinenergy’s 32KHZ AC inductor is one kind of AC inductor that could work in high frequency, with the special structure and advanced materials, the 32KHZ AC inductor with the better performance in the electrical circuit.

Shinenergy’s amorphous core AC inductor is the typical AC inductor with amorphous core, with all properties of AC inductor and performs better compared with the typical AC inductor.

Shinenergy’s MPP core AC inductor is one kind of AC inductor, all AC inductors with the similar function but different for different cores and winding materials, MPP core is one kind of power core with advanced characteristics.

- Data Sheet

- Product Brochure

High Frequency Inductors Data Sheet | |

| Rate of Work | 1.5kW-450kW |

| Rated Current | 5A-400A |

| Frequency | 10kHZ-200kHZ |

| Inductance | 0.13mH-16mH |

| Core Material | AMORPHOUS CORES/FERRITE CORES/INDUCTOR TYPES |

| Winding Material | Copper or Aluminum |

| Application | PV Power Supply/Energy Storage Power Supply/Vehicle Power Supply/Charging Pile Power Supply/Uninterruptible power supply/Data center power supply |

The symbol for an inductor in circuit diagrams is typically a coiled line or series of loops, representing the coiled wire that constitutes an inductor. This symbol visually suggests the coil’s magnetic field properties, which are central to its function.

An inductor is an electronic component that stores energy in a magnetic field when current flows through it. It resists changes in current, making it essential for controlling and stabilizing electrical circuits in devices like transformers, filters, and power supplies.

The inductance (L) of an inductor is calculated with the formula L=N2⋅μ⋅A/l, where N is the number of turns,μ is the core material’s permeability, AAA is the coil’s cross-sectional area, and l is the coil length. This formula determines inductance in Henrys (H).

An inductor diagram typically illustrates a coiled wire, sometimes alongside relevant values like inductance, core material, and physical dimensions. In circuit diagrams, it appears as a zigzag line or loop series, symbolizing its coiled structure and magnetic field behavior.

The main function of an inductor is to resist changes in current by creating a magnetic field. This makes inductors ideal for applications requiring current smoothing, filtering, and energy storage, such as in power supplies, tuned circuits, and electromagnetic interference filters.

Inductors vary by design and application, with types including air-core, iron-core, and ferrite-core inductors. Others include choke inductors for filtering, toroidal inductors for space-saving designs, and variable inductors for adjustable inductance. Each type serves specific circuit requirements based on its magnetic properties.

Shinenergy’s Isolation Transformers: Ensuring Safety and Reliability for Your Power Systems

Shinenergy’s inductors are designed to deliver unmatched power efficiency and stability. With advanced customization options tailored to your exact specifications, our inductors meet the demands of high-frequency, high-load applications, whether for PV energy storage, data centers, or EV charging stations. Leveraging top-grade materials and precise engineering, Shinenergy provides inductors that optimize your system’s performance and reliability, backed by our commitment to quality and innovation. Trust Shinenergy for inductors that power your success.