High Frequency Transformer for Rail

Shinenergy’s high-frequency transformer for rail could work at a high frequency of more than 16KHZ, widely applied in the rail traction system. It’s mainly applied to full bridge DC/DC converters.

- Wide operating frequency range from 16KHZ to 200KHZ

- Rated voltage: up to 25kV

- Power capacity is high up to 2800KVA

- CE, UL certificated

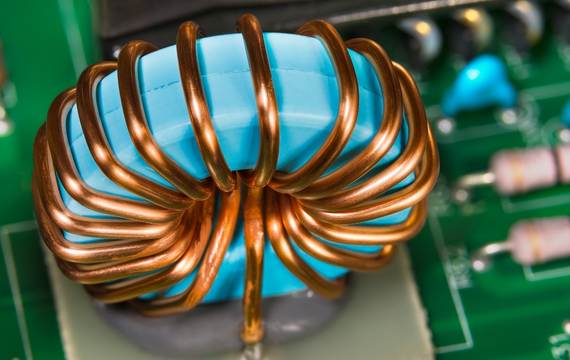

Customized Geometry Ferrite Core

Typically high frequency transformers use the ferrite core, different kinds of geometries of ferrite core are available, and whatever additional shielding or a specific form factor from clients, a ferrite core might meet the requirement.

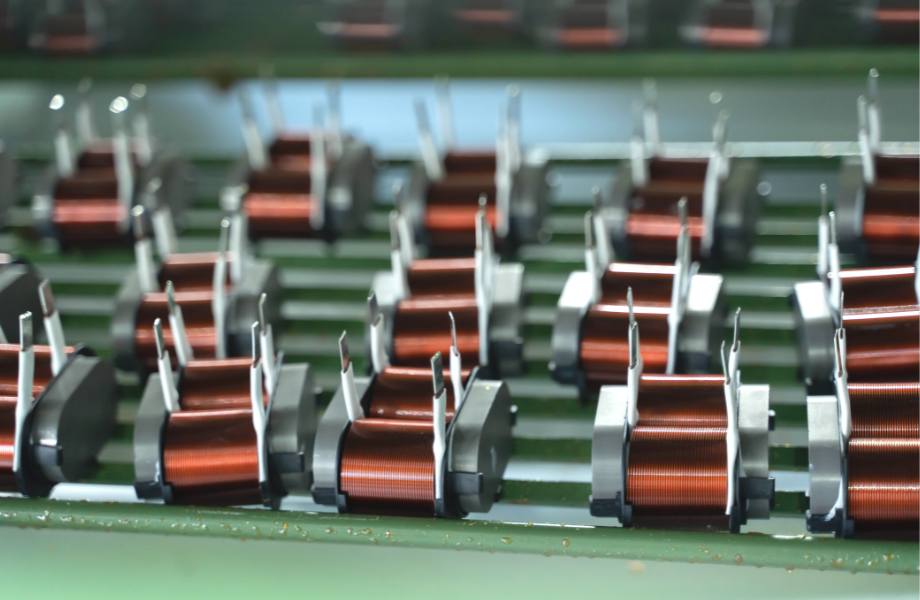

Liz Wire Reduce the Loss

Shinenergy’s high-frequency transformer cooperated with Liz wire to reduce the skin effect, thereby reducing the loss, Litz wire is a multistrand wire, this wire is designed to reduce the skin effect, it’s constructed of many thin wire strands, and the size of each individual strand is determined by the intended working frequency.

- Data sheet

- FAQs

| Model No. | MPT-016 |

| Application | Rails |

| Core Material | Ferrite |

| Winding Material | Liz Wire |

| Ratio | 1.57 |

| Frequency | 16~20KHz |

| Insulation Voltage | DC2600V |

| Weight | 24KG |

- What is a High Frequency Transformer for Rail?

- It’s a transformer designed specifically for railway applications, operating at higher frequencies than standard transformers to provide power conversion and supply in rail systems.

- How do High Frequency Transformers Differ from Standard Transformers in Rail Applications?

- These transformers are tailored for high frequency operation, which makes them more efficient and compact for the unique demands of rail systems, including onboard electronic systems and signaling.

- What are the Main Uses of High Frequency Transformers in Rail Systems?

- They are used in a variety of applications, including power supply for onboard electronics, lighting, air conditioning systems, and in signaling and communication systems.

- Why is High Frequency Operation Important in Rail Applications?

- High frequency allows for smaller, lighter transformers, which is crucial in rail applications where space and weight are significant considerations.

- Are High Frequency Transformers More Efficient?

- Yes, they tend to be more efficient, especially in applications where size and weight reduction are important, as is often the case in rail systems.

- What are the Key Features to Look for in a High Frequency Transformer for Rail?

- Key features include high efficiency, compact size, lightweight design, durability, and the ability to withstand vibrations and harsh conditions typical in rail environments.

- How Do Environmental Conditions Affect High Frequency Transformers in Rail?

- These transformers must be robust to withstand varying environmental conditions such as temperature fluctuations, humidity, and vibrations common in rail applications.

- Can High Frequency Transformers be Customized for Specific Rail Applications?

- Yes, many manufacturers offer customization options to meet specific requirements of different rail systems.

- What Maintenance Do High Frequency Transformers for Rail Require?

- They typically require minimal maintenance, but regular checks for wear, tear, and environmental impact are advised.

- Are High Frequency Transformers in Rail Systems Subject to Regulatory Standards?

- Yes, they must comply with specific industry and safety standards to ensure reliability and safety in the demanding rail environment.

Main Features of the High Frequency Transformer

High-frequency transformers operate at high frequencies from 16KHZ to over 1MHz, with the higher frequency, the transformer could be smaller, and the smaller size needs fewer wires, thereby reducing the losses and making the transformer more efficient, secondly, the core is typically ferrite, different kinds of geometries are available. Thirdly, the Litz wire could reduce the skin effect to reduce the losses.