Industrial systems require a reliable and efficient power supply to enable them to run smoothly and avoid downtime that can result in significant losses. Big current AC reactors are a critical component of these systems, providing an optimal solution to handle high energy requirements in industrial applications.

At Advanced Power Solutions, we offer a range of big current AC reactors to match various industrial applications’ specific needs. Our products are designed to deliver enhanced energy efficiency and performance, ensuring smooth operation and reliable power supply.

Understanding Big Current AC Reactors

Big current AC reactors are essential components of electrical systems in industrial settings. These reactors are designed to handle high currents efficiently and reliably. They help regulate the flow of electricity, preventing damage to electrical equipment and ensuring stable system performance.

Their primary function is to limit the flow of current in the electrical system, avoiding excessive power loss or equipment failure. Big current AC reactors can reduce the voltage spikes that can affect sensitive equipment and affect system stability. They work well with other power protection devices, such as surge protectors and circuit breakers.

In summary, big current AC reactors play an important role in ensuring safe and efficient operation of electrical systems in industrial applications. They work by regulating current flow and preventing damage to equipment, contributing to overall system performance.

Benefits of High Voltage AC Reactors

Using high voltage AC reactors comes with numerous benefits, especially for industrial applications. These reactors offer superior energy efficiency, resulting in reduced power losses and enhanced overall system performance. In addition, they can be customized to meet specific requirements, ensuring optimal functionality in critical operations.

With high voltage AC reactors, system efficiency is improved due to their ability to provide stable and reliable power in the face of varying loads. This stability ensures that the equipment connected to the power source does not suffer from the negative effects of unstable voltage. As a result, energy wastage is significantly reduced, leading to lower electricity bills and increased savings.

The use of high voltage AC reactors is particularly relevant in applications where large amounts of electrical power are needed. These reactors can handle high currents while maintaining high power factor ratings, making them ideal for industrial systems such as electric motors, lighting systems, and other heavy-duty equipment. Furthermore, their energy-efficient design contributes to reducing greenhouse gas emissions, promoting sustainability in industrial operations.

Overall, high voltage AC reactors provide a reliable and cost-effective solution for industrial power supply needs, enhancing efficiency, and profitability. With their advanced energy efficiency features, they are positioned to revolutionize power systems in the industry for years to come.

Enhancing Power with High Power AC Reactors

High power AC reactors play an essential role in industrial settings, where the need for a reliable and consistent power supply is critical. They supply large amounts of electrical energy, making them suitable for high-power applications such as manufacturing, mining, and energy generation. High power AC reactors support heavy-duty equipment, ensuring that they operate optimally even under the most challenging conditions.

The significance of high power AC reactors in industrial processes cannot be understated. They offer reactive energy compensation and voltage stabilization, thus improving system efficiency, reducing power losses, and extending the operating life of equipment. These reactors help to protect sensitive equipment from power surges and harmonic distortion, thus preventing system failures and costly downtime.

When selecting a high power AC reactor, it’s crucial to consider factors such as power rating, current and voltage ratings, and acceptable temperature range. It’s also essential to select a reactor that’s specifically designed for the intended application to guarantee maximum performance and reliability.

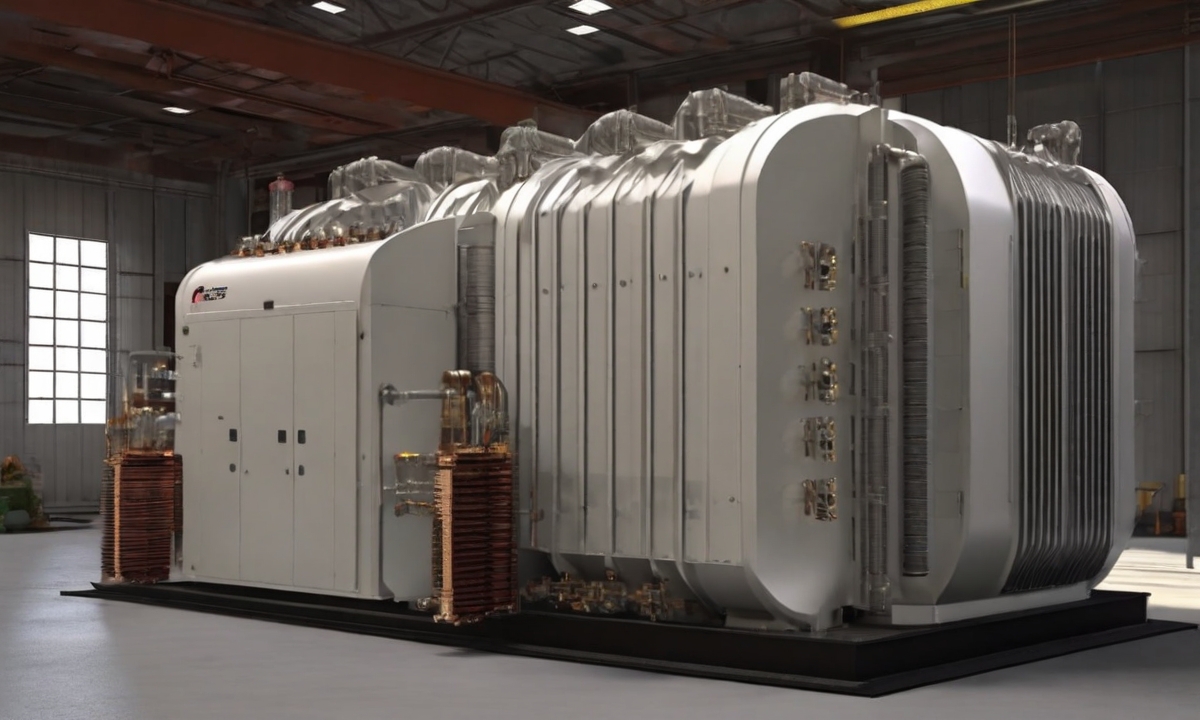

Large Scale AC Reactors for Industrial Applications

Large scale AC reactors play a vital role in handling substantial electrical loads in industrial settings. These reactors are necessary for many industries, including manufacturing, mining, and energy generation, as they ensure reliable and uninterrupted power supply to industrial processes.

In industrial applications, large scale AC reactors have the ability to regulate and control real power, reactive power, and ensure optimal power factor correction. They are designed to handle high voltage, high current, and complex electrical systems while minimizing harmonic distortion, improving power quality, and reducing overall energy consumption.

Industrial AC reactors come in different sizes and designs, allowing for customization to meet specific requirements for various applications. From simple air-core reactors to more advanced iron-core reactors, these solutions are engineered with the latest technologies to offer enhanced reliability and high-performance operation, reducing downtime and maintenance costs in industrial systems.

Overall, large scale AC reactors are essential power solutions that play a critical role in ensuring the efficient and reliable operation of industrial systems. When selecting an industrial AC reactor, factors such as current capacity, voltage range, energy efficiency, and custom design should be taken into consideration to ensure optimal system performance.

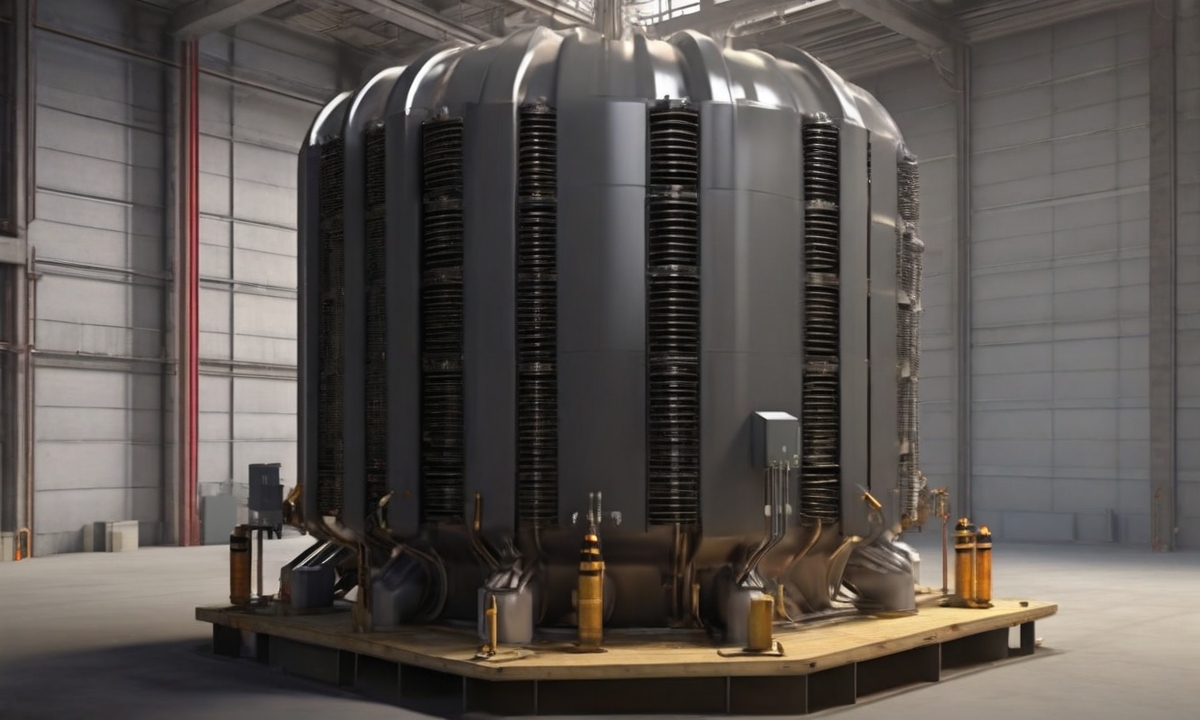

Exploring Advanced AC Reactor Technology

With the continued growth of industrial applications, there has been a need for advanced AC reactor technology that offers enhanced reliability and high-performance operation. Manufacturers have responded by developing reactors with new features to support uninterrupted power supply in critical applications.

One major advancement in AC reactor technology is the implementation of self-cooled designs that reduce the risk of overheating and system failure. This approach improves the efficiency of energy transfer while maintaining the overall quality of the reactor’s performance, thus reducing running costs for businesses in the long-term.

Another area of innovation is the development of intelligent control systems. These systems use advanced data analytics to monitor and adjust system behavior in real-time, optimizing performance and ensuring energy efficiency. In addition, some AC reactors now feature high-speed switching technology, enabling immediate switching between operation modes to better handle fluctuating electrical loads.

Overall, the latest developments in AC reactor technology are enabling reactors to offer greater reliability, enhanced efficiency, and high-performance operation, all of which contribute to uninterrupted power supply in critical applications.

Custom AC Reactor Design for Specific Requirements

Custom AC reactor design plays a vital role in meeting specific industrial requirements. Customized reactors are tailored to meet specific voltage, power, and environmental conditions, ensuring optimal performance and efficiency. The design process takes into consideration the application, power quality issues and the specific technical requirements of the system.

With custom AC reactor design, industries can significantly reduce energy losses, improve power quality and avoid equipment failure due to unforeseen system conditions. At the same time, achieving optimal performance and efficiency in the system.

Factors to Consider When Choosing an AC Reactor

Choosing the right AC reactor requires careful consideration of several factors, including:

Current Capacity

The current capacity of the reactor should align with the demand of your electrical system. Consider the maximum current your system may draw and ensure you choose a reactor with appropriate capacity.

Voltage Range

Similarly, choose an AC reactor with a suitable voltage range that aligns with your power system requirements.

Energy Efficiency

Select an AC reactor that is energy efficient and will minimize power losses. This helps to ensure optimal system performance and cost savings on your power bills.

Reliability

Reliability is critical when choosing an AC reactor. Look for a product that has a long service life and won’t fail prematurely, causing downtime and productivity loss.

Custom Design

Custom-designed AC reactors can be tailored to the specific demands of your electrical system, ensuring optimal performance and efficiency. Consider the benefits of custom design when selecting an AC reactor.

Type of Application

Another factor to consider is the type of industrial application for which the AC reactor will be used. Some applications may require large-scale or high-power reactors, while others may require energy-efficient solutions. Choose a reactor that aligns with your specific application requirements.

By taking all these factors into account, you can select a high-performance, reliable, and energy-efficient AC reactor that offers optimal performance and longevity for your industrial needs.

Conclusion

In conclusion, big current AC reactors offer advanced power solutions that are crucial for industrial applications. Understanding the different types of reactors, such as high voltage, high power, and large-scale reactors, is necessary to select the right solution for specific requirements. The benefits of using custom design reactors cannot be overstated as they ensure optimal performance and efficiency. Energy efficiency and reliability are critical for industrial systems, and advanced AC reactor technology can help achieve both. By considering factors such as current capacity, voltage range, energy efficiency, and reliability, industries can select the most suitable AC reactor for their needs.

FAQ

What is a big current AC reactor?

A big current AC reactor is a type of power electronic device designed to handle high electrical currents in industrial settings. It is used to regulate and control the flow of current in AC power systems, ensuring stable and reliable operation.

How do big current AC reactors work?

Big current AC reactors work by introducing impedance into the electrical circuit. They restrict the flow of current, providing protection and stability to the system. The reactors are typically connected in series with the load, absorbing unwanted harmonics and improving overall power quality.

What are the benefits of using high voltage AC reactors?

High voltage AC reactors offer several advantages. They help reduce power losses, improve the efficiency of electrical systems, and enhance power quality. These reactors protect sensitive equipment, mitigate voltage fluctuations, and contribute to overall energy savings.

How do high power AC reactors enhance power supply?

High power AC reactors are designed to handle substantial electrical loads reliably. They increase the power supply capacity in industrial applications, enabling the smooth operation of high-power machinery and equipment. These reactors ensure stable voltage and current levels, protecting the equipment and optimizing system performance.

What are some industrial applications of large scale AC reactors?

Large scale AC reactors find applications in various industries such as manufacturing, mining, and energy generation. They are used in heavy machinery, industrial automation systems, renewable energy plants, and high-power data centers, among others. These reactors support the efficient and reliable operation of these industrial processes.

What advancements have been made in AC reactor technology?

AC reactor technology has advanced significantly in recent years. Modern reactors are built with enhanced reliability features, high-performance operation, and improved energy efficiency. They incorporate advanced materials, optimized designs, and intelligent control systems to ensure uninterrupted power supply and optimal system performance.

Can AC reactors be customized for specific requirements?

Yes, AC reactors can be customized to meet specific requirements. Custom design allows for the adaptation of reactors to suit unique industrial applications. Factors such as current capacity, voltage range, and mounting options can be tailored to optimize performance and efficiency.

What factors should be considered when selecting an AC reactor?

When choosing an AC reactor, several factors should be considered. These include the required current capacity, voltage range, energy efficiency, reliability, and the benefits of custom design. It is essential to select a reactor that aligns with the specific requirements of the application and the overall power system.

Pingback: ประกันชีวิตในอเมริกา