If you are working with industrial equipment that requires voltage conversion, it is crucial to choose the right transformer to ensure safe and efficient operation. In this guide, we will discuss the importance of selecting the appropriate 208V to 240V 3 phase buck boost transformer. We will provide an overview of power systems, examine the concept of a buck boost transformer, highlight the advantages of using a 208V to 240V buck boost transformer, and guide you on important factors to consider when choosing a transformer.

Understanding 208V and 240V Power Systems

Before delving into the specifics of 208V to 240V conversion and buck boost transformers, it is crucial to understand the difference between the two power systems.

In the United States, the most commonly used three-phase voltage levels are 208V and 240V. 208V systems are commonly found in commercial buildings, while 240V systems are more prevalent in industrial settings. The key difference between the two is that 208V systems use a Y configuration with three phases and a neutral, while 240V systems use a Delta configuration with three phases and no neutral.

While 208V and 240V power systems are designed for specific applications, there are instances where voltage conversion is necessary. This is where buck boost transformers come into play.

Keep reading to learn more about buck boost transformers and their role in converting voltage levels for safe and efficient operation of industrial equipment.

What is a Buck Boost Transformer?

A buck boost transformer is a type of electrical transformer that is used to adjust the voltage levels of alternating current (AC) electrical power. It is a type of transformer that can provide either an increase or decrease in the voltage level. The buck boost transformer is also known as an autotransformer because it has a single winding that serves both as the primary and secondary windings.

The operation of a buck boost transformer is based on the principle of Faraday’s law of electromagnetic induction, which states that a time-varying magnetic field induces an electromotive force (EMF) in a nearby conductor. In a buck boost transformer, the input voltage is applied to the primary winding, which generates a magnetic field. The magnetic field then induces a voltage in the secondary winding, which can be either higher or lower than the input voltage depending on the winding turns ratio.

Buck boost transformers are commonly used in industrial applications, such as in voltage regulators, motor starters, and welding machines. They are also used in residential and commercial applications, such as in air conditioning units and lighting systems.

Overall, buck boost transformers play a crucial role in adjusting voltage levels to meet specific requirements in various applications.

Advantages of Utilizing a 208V to 240V Buck Boost Transformer

In industrial settings where electrical equipment requires power at different voltage levels, a buck boost transformer can be a game-changer. By converting voltage levels from one level to another, a buck boost transformer can improve equipment performance, increase energy efficiency, and generate cost savings. Let’s explore some of the key advantages of using a 208V to 240V buck boost transformer:

Improved Equipment Performance

A buck boost transformer helps to optimize the performance of electrical equipment by providing voltage levels that are aligned with the specific requirements of the equipment. By stabilizing voltage levels, a buck boost transformer can help to prevent equipment malfunction due to under or overvoltage issues.

Energy Efficiency

By ensuring the electrical equipment is operating at the right voltage level, you can reduce energy waste. A buck boost transformer can help you achieve this by converting voltage levels to the required level, meaning the equipment will only receive the energy it needs to operate efficiently.

Cost Savings

By improving equipment performance and reducing energy wastage, a buck boost transformer can generate significant cost savings over time. Investing in a buck boost transformer can save on electric bills and minimize costly equipment repairs caused by under or overvoltage issues.

Factors to Consider When Choosing a Buck Boost Transformer

When choosing a buck boost transformer, it is crucial to consider various factors to ensure that you get the best transformer that fits your needs. The following are important factors to consider:

Load Requirements

Define the load requirements, including the power demands for all devices and equipment to determine the size and capacity of the transformer.

Voltage Characteristics

Understand the voltage characteristics of the primary and secondary systems, ensuring compatibility and preventing overvoltage/undervoltage issues.

Transformer Capacity

Choose a transformer with sufficient capacity to meet current load demands, while taking into account any potential future expansion requirements.

Buck Boost Transformer Calculator

Using a reliable buck boost transformer calculator can help simplify the process of selecting the right transformer by calculating the required capacity based on the entered load and voltage characteristics.

By considering these factors, you can ensure that you choose the best buck boost transformer for your specific needs, leading to optimal performance and efficient voltage conversion.

Types of 208V to 240V Buck Boost Transformers

A buck boost transformer is a type of electrical transformer that allows for voltage adjustments in industrial applications. In the market, there are various types of 208V to 240V buck boost transformers available to meet different applications’ needs.

Single-Phase Buck Boost Transformers

Single-phase transformers are typically used where the power application has lower voltage and power requirements. These transformers are more cost-effective and smaller than three-phase transformers. They are ideal for smaller applications such as lighting, small motors, and low voltage equipment.

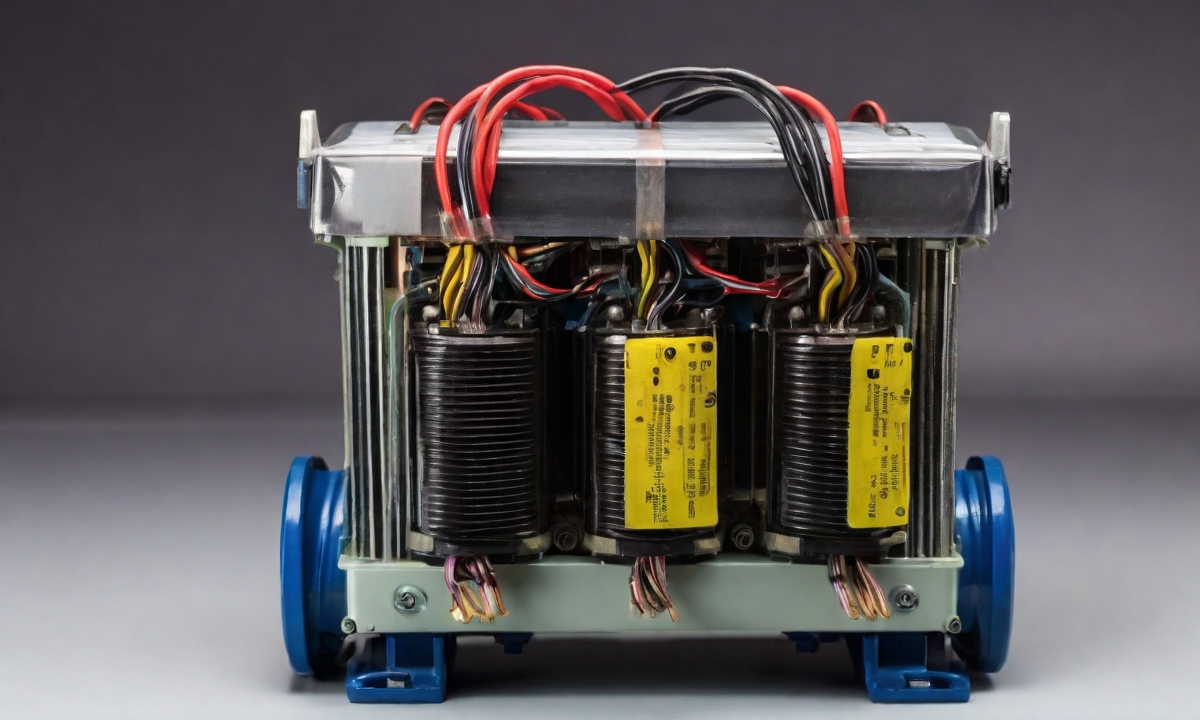

Three-Phase Buck Boost Transformers

Three-phase transformers are designed for higher voltage and power requirements than single-phase transformers. They are commonly used in high-voltage power distribution and industrial applications. Three-phase buck boost transformers are ideal for applications such as air conditioning units, motors, and pumps.

It is important to choose the right transformer for your application to ensure optimal performance. A professional electrician or engineer can help you determine which type of buck boost transformer is best for your specific needs.

Installation and Wiring Considerations

Proper installation and wiring of a 208V to 240V buck boost transformer is critical for safe and efficient operation. Before beginning installation, ensure that the transformer matches your specific voltage requirements and load capacity needs.

When mounting the transformer, it should be kept in a dry location and away from any potential sources of physical damage or interference. The transformer should be grounded according to national and local electrical codes, and the grounding wire should be connected securely.

Wiring connections should also be made carefully, using appropriate wire sizes and wire nuts. Be sure to carefully follow the wiring diagram provided by the manufacturer to avoid any mistakes that could result in electrical hazard or equipment damage.

It’s important to also verify that the wiring and connections are done correctly before powering up the transformer. A voltage test should be conducted to ensure that the voltage is being properly regulated by the transformer.

Overall, proper installation and wiring practices are essential to maximizing the lifespan and performance of a 208V to 240V buck boost transformer. If you are unsure of how to properly install or wire the transformer, consult a licensed electrician or the manufacturer for guidance.

Maintenance and Safety Guidelines

Proper maintenance and safety practices are crucial to ensuring the reliable performance and longevity of your 208V to 240V buck boost transformer. Here are some essential guidelines to keep in mind:

- Regularly inspect the transformer for signs of wear or damage.

- Ensure that the transformer is installed in a well-ventilated area and that there is adequate clearance around it.

- Check the transformer’s oil level and cleanliness regularly. Dirty or low oil levels can cause damage to the transformer.

- Do not attempt to operate the transformer outside of its rated capacity.

- Always shut off power to the transformer before performing any maintenance or repairs.

Remember that working with electrical transformers can be dangerous, and caution should always be exercised. If you are unsure about any aspect of maintenance or repair, contact a qualified electrician or technician for assistance.

“Neglecting maintenance or failing to follow safety protocols can result in serious damage to the transformer, as well as posing a safety hazard to people working nearby.”

Popular Brands and Manufacturers

When it comes to purchasing a high-quality 208V to 240V buck boost transformer, it’s essential to choose a reliable brand with a proven track record. Here are some of the leading manufacturers in the industry:

1. Acme Electric Corporation

Acme Electric Corporation is a well-respected manufacturer of high-performance transformers and power conversion equipment. Their buck boost transformers are designed to deliver excellent voltage regulation and are known for their durability and efficiency.

2. Hammond Power Solutions

Hammond Power Solutions is known for producing a wide range of high-quality transformers for various applications, including industrial, commercial, and residential settings. Their buck boost transformers offer superior performance, robust construction, and long-term reliability.

3. Eaton Corporation

Eaton Corporation is a global leader in electrical equipment manufacturing, offering a broad range of products for industrial, commercial, and residential applications. Their buck boost transformers are designed to provide outstanding voltage regulation with minimal maintenance requirements.

4. Federal Pacific

Federal Pacific is a trusted brand that has been producing electrical equipment for over 50 years. Their buck boost transformers are designed for demanding industrial applications and provide reliable and efficient voltage regulation.

These are just a few examples of the reputable brands and manufacturers that offer excellent 208V to 240V buck boost transformers. It’s essential to do your research and choose a transformer that meets your specific requirements and offers the best value for your investment.

Troubleshooting Common Issues

Despite their reliability, 208V to 240V buck boost transformers may experience issues over time. The following are some of the most common issues and their corresponding troubleshooting tips:

1. Overheating

Overheating is a common issue that may occur due to various factors such as inadequate cooling, overloaded transformer, or inadequate ventilation. To address this issue, you should:

- Check for any obstructions blocking the airflow around the transformer and remove them.

- Ensure that the transformer is adequately ventilated according to the manufacturer’s guidelines.

- Ensure that the transformer is not overloaded and that the load is distributed evenly among all phases.

- Consider installing a cooling system such as a fan or heat sink to dissipate heat.

2. No Output Voltage

If the buck boost transformer fails to deliver rated voltage output, the following steps can be performed to troubleshoot the issue:

- Ensure the primary and secondary wiring connections are correct.

- Check if the transformer is overloaded and reduce the load to an appropriate level.

- Check if the input voltage matches the specifications of the transformer.

- Inspect the transformer windings for any damage that may cause a short circuit or open circuit.

3. Buzzing or Humming Noise

Another common issue that may arise is a buzzing or humming noise emitted by the transformer. The possible causes of this issue and their troubleshooting tips include:

- Ensure that the transformer is properly grounded.

- Tighten any loose connections or hardware that may cause vibration.

- Check and replace any damaged components such as the core or winding.

- Inspect the transformer for any signs of loose windings or damage to the core.

By following these troubleshooting tips, you can resolve common issues with 208V to 240V buck boost transformers and ensure safe and efficient operation.

Conclusion

When it comes to choosing the right transformer for your industrial applications, there are several factors you need to consider. One of the most critical factors is the ability to convert voltage from 208V to 240V reliably and efficiently. In this guide, we have explored the essential aspects of buck boost transformers and their role in adjusting voltage levels to meet specific requirements.

We began by discussing the difference between 208V and 240V power systems and the need for voltage conversion. Then, we delved into the concept of buck boost transformers and the advantages of using them in industrial settings. We also covered the important factors to consider when selecting a transformer, such as load requirements and voltage characteristics.

Furthermore, we explored the different types of buck boost transformers available on the market and their suitability for various applications. We provided guidance on proper installation, wiring practices, and essential maintenance practices to ensure longevity and reliable performance of a 208V to 240V buck boost transformer.

Lastly, we shared some reputable brands and manufacturers known for producing high-quality buck boost transformers and addressed common issues that may arise with them.

In summary, selecting the right 208V to 240V 3 phase buck boost transformer is crucial for efficiency, safety, and cost savings in industrial applications. We hope this guide has provided you with valuable insights to help you make informed purchasing decisions.

References

1. Buck-Boost Transformers Explained. (2021). Acme Electric. Acme Electric. https://www.acmepowerdist.com/wp-content/uploads/2019/08/Buck-Boost-Transformers-Explained.pdf

2. Buck-Boost Transformers. (2021). Electrician’s Toolbox Etc. Electrician’s Toolbox Etc. https://www.electricianstoolbox.com/buck-boost-transformers/

3. Buck-Boost Transformers: What They Are & How They Work. (2021). Bay Power. Bay Power. https://www.baypower.com/buck-boost-transformers-what-they-are-how-they-work/

4. Electrical Transformer Basics. (2021). Energy.gov. Energy.gov. https://www.energy.gov/sites/default/files/2017/03/f34/transformerbasics.pdf

5. How to Choose and Size a Buck-Boost Transformer. (2021). Acme Electric. Acme Electric. https://www.acmepowerdist.com/wp-content/uploads/2019/08/How-to-Choose-and-Size-a-Buck-Boost-Transformer.pdf

6. Transformers. (2021). Grainger. Grainger. https://www.grainger.com/category/power-transmission/electrical-power-generation/transformers

7. Understanding Buck-Boost Transformers. (2021). EEP – Electrical Engineering Portal. EEP – Electrical Engineering Portal. https://electrical-engineering-portal.com/understanding-buck-boost-transformers

FAQ

What is a buck boost transformer?

A buck boost transformer is an electrical device that allows for the adjustment of voltage levels to meet specific requirements. It is commonly used to convert voltage from 208V to 240V in industrial applications.

Why would I need a 208V to 240V buck boost transformer?

You might need a 208V to 240V buck boost transformer if your equipment or machinery requires a higher voltage level than what is available in your power system. It ensures safe and efficient voltage conversion for optimal performance.

How does a buck boost transformer work?

A buck boost transformer works by utilizing the principles of magnetic induction and electrical impedance to adjust voltage levels. It consists of primary and secondary windings wound around a magnetic core, enabling the transformation of voltage to the desired level.

What are the advantages of using a 208V to 240V buck boost transformer?

Using a 208V to 240V buck boost transformer offers several benefits, including improved equipment performance, energy efficiency, and cost savings. It ensures that your machinery operates at the correct voltage level, reducing the risk of damage or malfunction.

What factors should I consider when choosing a buck boost transformer?

When selecting a buck boost transformer, you should consider factors such as the load requirements, voltage characteristics, and transformer capacity. It is essential to choose a transformer that can handle the specific demands of your equipment.

What are the different types of 208V to 240V buck boost transformers available?

There are different types of 208V to 240V buck boost transformers available, including single-phase and three-phase options. The type you choose depends on the specific application and power system requirements.

What are the installation and wiring considerations for a buck boost transformer?

Proper installation and wiring are crucial for the safe and effective operation of a buck boost transformer. It is essential to follow the manufacturer’s guidelines and local electrical codes to ensure correct and secure installation.

What maintenance and safety guidelines should I follow for a buck boost transformer?

To ensure the longevity and reliable performance of a buck boost transformer, regular maintenance practices should be followed. This includes inspections, cleaning, and regular testing. Additionally, it is important to adhere to safety guidelines to prevent accidents and electrical hazards.

Which brands and manufacturers are known for producing high-quality 208v to 240v 3 phase buck boost transformer?

There are several reputable brands and manufacturers known for producing high-quality 208v to 240v 3 phase buck boost transformer, including ABB, Schneider Electric, Siemens, and Eaton. It is advisable to research and choose a trusted brand to ensure product reliability and performance.

What are some common issues with buck boost transformers, and how can they be troubleshooted?

Some common issues with buck boost transformers include overheating, voltage fluctuations, or improper voltage conversion. If you encounter such issues, it is recommended to consult a qualified electrician or the manufacturer for troubleshooting guidance.

Pingback: รับทำตรายาง

Pingback: คลินิกทันตกรรม กระบี่