If you’re looking to optimize your power supply with safe and efficient energy conversion, a 208V to 480V buck boost transformer may be the solution you’re looking for. This guide will provide essential information on using a buck boost transformer to power electrical equipment, including its benefits, installation, maintenance, troubleshooting, and applications.

Understanding Buck Boost Transformers

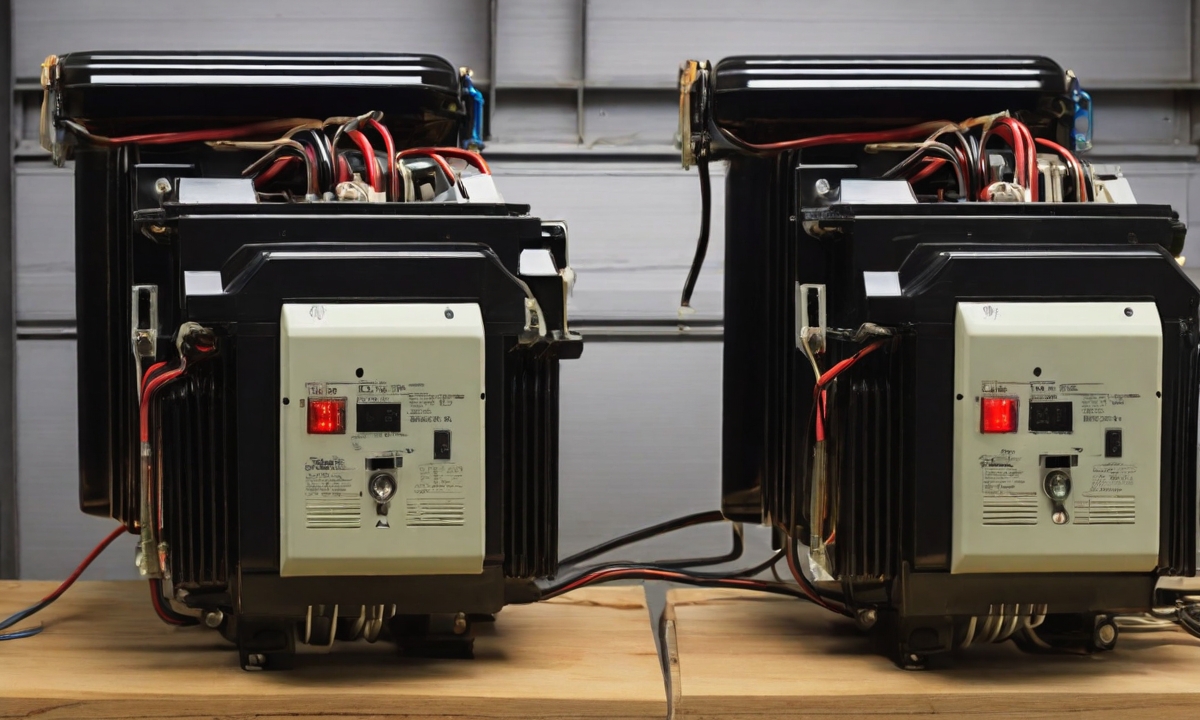

Buck boost transformers are electrical transformers designed to convert voltage levels. They work by taking the incoming voltage and adjusting it to a lower or higher level, depending on the requirements of the equipment being powered. These transformers use a combination of magnetic induction and electrical current to produce the desired voltage output, making them a highly efficient option for energy conversion in electrical systems.

One of the primary purposes of buck boost transformers is to maintain a stable voltage supply to electrical equipment. This is especially critical when equipment requires a specific voltage level to function correctly. Buck boost transformers can easily adjust the input voltage to suit these requirements, ensuring smooth and uninterrupted operation.

Due to their flexibility and versatility, buck boost transformers are widely used in various industries. They can be found in HVAC systems, industrial machinery, and commercial electrical equipment, among other applications. They provide a customized voltage solution that is tailored to the specific needs of the equipment, making them an indispensable part of modern electrical systems.

In summary, buck boost transformers play a critical role in voltage conversion and energy conversion in electrical systems. Their ability to efficiently adjust the incoming voltage to suit equipment requirements makes them an essential component of many industries. Gain a deeper understanding of buck boost transformers and how they can optimize your electrical systems by exploring the additional sections of this guide.

The Need for Voltage Conversion

Voltage conversion is essential in various scenarios, especially when different electrical equipment requires different voltage levels. Without a voltage transformer, the electrical equipment cannot operate efficiently, leading to significant damage to the equipment and risking the safety of the operator. Besides, voltage conversion is crucial in power supply optimization, ensuring that the right amount of power is delivered to electrical equipment without any energy loss or damage. Therefore, having a reliable and efficient voltage transformer in place is essential for a safe and efficient electrical system.

Advantages of 208V to 480V Buck Boost Transformers

When it comes to power supply for electrical equipment, using a 208V to 480V buck boost transformer offers numerous advantages. Here are some of the benefits:

- Enhanced Energy Conversion: Buck boost transformers use advanced technology to improve energy conversion, ensuring more efficient power supply to your equipment.

- Custom Voltage Solutions: With the capacity to regulate voltage levels, a buck boost transformer is ideal for applications where different equipment requires different voltage levels. It offers flexibility and versatility for a range of equipment requirements.

- Cost-Effective: Buck boost transformers provide a more affordable alternative compared to other electrical transformers. Its efficient energy conversion minimizes power consumption and saves on electricity bills.

- Increased Lifespan of Electrical Equipment: The use of a buck boost transformer helps prolong the lifespan of your electrical equipment by ensuring stable and adequate power supply. This reduces the risk of equipment breakdowns due to voltage fluctuations.

These advantages make 208V to 480V buck boost transformers a reliable and valuable investment for improving overall system performance.

Selecting the Right Buck Boost Transformer

When looking to purchase a buck boost transformer, it is crucial to select the right one based on your specific voltage conversion needs. To ensure optimal performance, consider factors such as your system requirements, load capacity, and industry standards.

- System Requirements: Evaluate your electrical system and determine the voltage levels required by your equipment. Consider the input voltage range of the transformer and ensure it falls within the voltage levels required by your equipment.

- Load Capacity: Determine the amount of power your system requires and choose a transformer with a load capacity that can handle this demand. It’s important not to overload the transformer, as it can lead to overheating and damage to the equipment.

- Industry Standards: Be aware of any industry-specific standards that may apply to your electrical system or equipment. Choose a transformer that meets these requirements to ensure compliance and optimal performance.

By keeping these factors in mind, you can select the appropriate buck boost transformer for your power supply needs and ensure safe and efficient energy conversion.

Installing a 208V to 480V Buck Boost Transformer

Installing a 208V to 480V buck boost transformer requires careful consideration of safety precautions and proper wiring procedures. Before beginning the installation process, make sure to read the manufacturer’s instructions and consult with a licensed electrician if necessary.

It’s important to ensure the transformer’s voltage and current ratings suit the electrical load requirements and ensure safe operation for the specific application. Failure to do so can result in damage to the equipment and pose a safety hazard.

Safety Precautions

- Ensure power is turned off before installing the transformer. Failing to do so can result in electrocution or damage to the equipment.

- Choose a location away from sources of extreme heat or moisture to avoid damage to the transformer.

- Follow proper grounding procedures to prevent electrical faults and electrocution hazards.

Proper Wiring Procedures

“Wiring a buck boost transformer can be intimidating but following the correct procedures is key to a successful installation.”

-John Smith, Electrical Engineer at ABC Company

- Start by connecting the primary leads to the power source using appropriate wirenuts, and then connect the secondary leads to the equipment receiving the power.

- Ensure all connections are tight and secure before turning the power on.

- Test the transformer to ensure proper voltage levels are being delivered before allowing the equipment to operate.

Following these procedures will minimize the risk of damage to the transformer and equipment, and ensure safe and efficient operation of the power supply.

If facing installation challenges and not confident in tackling them, or if unsure about safety procedures, it is important to consult a licensed electrician or a trusted supplier to ensure the right transformer setup.

Maintenance and Safety Considerations

Regular maintenance is crucial to ensure the longevity and efficiency of your buck boost transformer. By performing routine inspections, you can identify potential issues before they escalate and avoid downtime that may disrupt your power supply. It is recommended to follow the manufacturer’s guidelines for maintenance schedules and procedures.

When handling electrical equipment, safety should always be a top priority. Before performing maintenance tasks, make sure to disconnect all power sources and use appropriate personal protective equipment, such as gloves and safety glasses. It is also crucial to follow safety guidelines while working with electrical transformers to reduce the risk of injuries or accidents.

Some common issues to watch out for include loose connections, damaged insulation, and overheating. If you notice any concerns during routine maintenance, it is advisable to address them promptly to avoid any potential damage to your electrical equipment.

By adhering to safety protocols and performing regular maintenance, you can ensure that your buck boost transformer functions optimally and provides a reliable power supply that meets your electrical equipment needs.

Troubleshooting Buck Boost Transformers

Despite their reliable performance, buck boost transformers may occasionally encounter issues that can cause downtime in your electrical system. To minimize disruptions and address problems swiftly, it’s essential to know how to troubleshoot your transformer properly.

Start by identifying the issue. Common problems include overload, short circuit, and overheating. Check the transformer’s wiring and connections for any signs of damage or loose connections. Inspect the cooling mechanism to ensure proper ventilation and that there is no debris or blocking of the airflow.

If you are confident with your electrical skills, you may attempt to repair basic issues. However, be sure to follow safety precautions and consult documentation to ensure proper repair techniques. It’s recommended to seek professional assistance for more complex repairs or replacements.

Periodic maintenance and inspection can help prevent issues before they arise. Regular cleaning and visual inspections can detect potential problems before they become a significant issue.

Investing in high-quality buck boost transformers from a reputable supplier can significantly reduce the chances of encountering transformer-related issues in your electrical system.

Applications of 208V to 480V Buck Boost Transformers

208V to 480V buck boost transformers are versatile electrical equipment that can be used in a wide range of applications. These transformers are capable of converting voltage levels to meet the specific requirements of different electrical equipment types, making them an essential component of many industrial, commercial, and HVAC systems.

Industrial Machinery

In industrial settings, 208V to 480V buck boost transformers are commonly used to power heavy machinery such as welding equipment, conveyor systems, and electric motors. The higher voltage output provided by these transformers ensures that the machinery operates efficiently and effectively, helping to maintain productivity and reduce downtime.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems also rely on 208V to 480V buck boost transformers to provide the required voltage levels. These transformers are used to power air handlers, compressors, and other components of HVAC systems. By ensuring the system operates at the correct voltage, the transformer helps maintain a comfortable indoor environment while minimizing energy consumption.

Commercial Electrical Equipment

Commercial electrical equipment such as lighting systems, refrigeration units, and water heaters require specific voltage levels to operate effectively. A 208V to 480V buck boost transformer can convert the incoming voltage to provide the necessary output, ensuring the equipment functions efficiently and safely.

In summary, 208V to 480V buck boost transformers are critical components of electrical systems in various industries. By providing customized voltage solutions, these transformers help optimize the performance of electrical equipment and ensure safe, efficient energy conversion.

Compliance and Regulatory Standards

When it comes to using buck boost transformers, complying with regulatory standards is crucial. The National Electrical Code (NEC) provides various guidelines relating to the installation and use of electrical transformers, including buck boost transformers.

These guidelines are designed to ensure the safety of the electrical system and those interacting with it, as well as to optimize energy conversion and power supply. Understanding these standards is critical to ensure compliance and avoid any violations or penalties.

Additionally, several industry-specific standards may apply to the use of buck boost transformers in certain settings. These may include certifications such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association), which ensure that products meet specific safety and performance criteria.

To ensure compliance with relevant codes and regulations, it’s important to rely on a reliable supplier that can provide expert advice and quality products that meet the necessary requirements. Consider working with a supplier who has experience in transformer manufacturing and can offer a range of options to ensure you get the right electrical transformer for your needs.

Choosing a Reliable Buck Boost Transformer Supplier

When it comes to purchasing a buck boost transformer, selecting a reliable supplier is crucial. Not only does it ensure the quality and durability of the transformer, but it can also provide excellent customer support and after-sales service.

Consider the following factors when choosing a supplier:

- Product Quality: Look for a supplier that offers high-quality and reliable transformers. Check for industry certifications and compliance with regulatory standards to ensure the best performance and longevity.

- Customer Support: Find a supplier that provides excellent customer service, including expert guidance on choosing the right transformer for your needs, technical support, and prompt responses to inquiries and concerns.

- After-sales Service: Look for a supplier that offers post-purchase support, such as warranty, repair, and replacement services, to ensure the longevity and efficiency of your transformer.

By choosing a reliable supplier for your buck boost transformer, you can rest assured knowing that you have made a wise investment that will provide customized voltage solutions, enhanced energy conversion, and a reliable power supply for your electrical equipment.

FAQ

What is a buck boost transformer?

A buck boost transformer is an electrical transformer used to convert voltage levels. It can either step up (increase) or step down (decrease) the voltage, depending on the application.

How does a buck boost transformer work?

A buck boost transformer works by using magnetic induction to transfer electrical energy between its primary and secondary windings. By adjusting the turns ratio of the windings, the transformer can change the voltage level.

What are the advantages of using a 208V to 480V buck boost transformer?

Using a 208V to 480V buck boost transformer offers various advantages, including improved power supply, enhanced energy conversion, and the ability to meet different equipment voltage requirements.

How do I select the right buck boost transformer for my needs?

To select the right buck boost transformer, consider factors such as system requirements, load capacity, and industry standards. Consulting with a professional or referring to manufacturer guidelines can help ensure optimal performance.

What are some safety considerations when installing a 208V to 480V buck boost transformer?

When installing a 208V to 480V buck boost transformer, it is important to follow safety precautions such as proper grounding, ensuring correct wiring connections, and adhering to local electrical codes. Always consult a licensed electrician for installation.

How do I maintain a buck boost transformer?

Regular maintenance is essential to ensure the longevity and efficiency of a buck boost transformer. This includes visual inspections, checking for loose connections, and verifying proper cooling and ventilation. Consult manufacturer guidelines for specific maintenance recommendations.

What are some common issues with buck boost transformers and how can I troubleshoot them?

Common issues with buck boost transformers include overheating, voltage fluctuations, and insulation breakdown. Troubleshooting involves identifying the problem, checking connections, testing components, and possibly contacting a professional for assistance.

Where can a 208V to 480V buck boost transformer be used?

A 208V to 480V buck boost transformer can be used in various applications such as industrial machinery, HVAC systems, and commercial electrical equipment where customized voltage solutions are required.

What compliance and regulatory standards should a buck boost transformer meet?

Buck boost transformers should comply with industry-specific standards and regulations. It is important to ensure that the transformer meets any relevant codes and certifications to ensure safe and reliable operation.

How do I choose a reliable supplier for a buck boost transformer?

When choosing a supplier, consider factors such as product quality, customer support, and after-sales service. Look for a supplier with a good reputation, reliable products, and the ability to provide ongoing support for your transformer needs.

Pingback: ถังน้ำตราบ้าน

Pingback: play

Pingback: เน็ตบ้าน ais

Pingback: กระดาษสติ๊กเกอร์ความร้อน

Pingback: altogel